A kind of all-solid wound supercapacitor and preparation method thereof

A supercapacitor and solid electrolyte technology, applied in the field of electrochemical energy storage, can solve the problems that supercapacitors cannot achieve large bending and tight winding, and the area of supercapacitor self-supporting carbon nanomaterial-based flexible electrode materials is difficult to expand. Achieve the effects of improving safety and stability, portability, controllability, and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

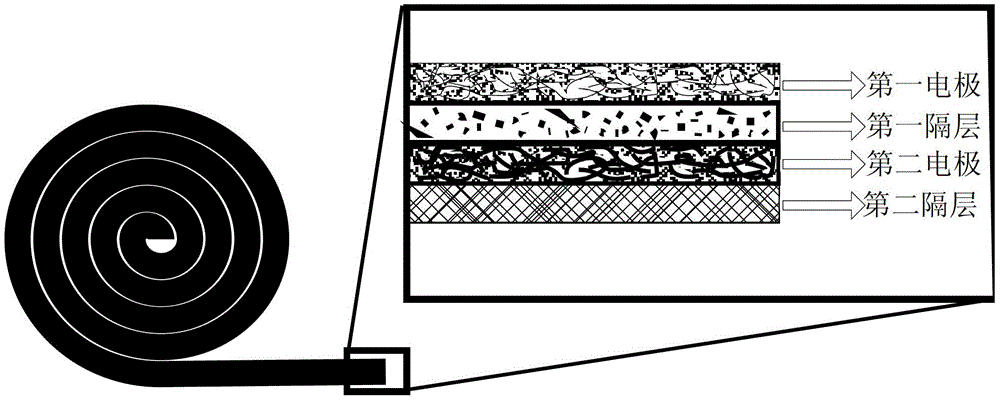

[0070] The preparation method of above-mentioned supercapacitor, may comprise the steps:

[0071] Step 1, placing the second electrode on the second interlayer;

[0072] If the second interlayer adopts a solid electrolyte, before the step 1, it also includes: hot dripping the solid electrolyte on the surface of the substrate, and using the glue-spinning method to uniform the glue to obtain a layer of uniform and flat solid electrolyte surface, as second compartment;

[0073] If the second interlayer adopts a solid electrolyte and an insulating layer, before the step 1, it also includes: first laying a layer of insulating film on the surface of the substrate, and then thermally dripping the solid electrolyte onto the insulating film. , as a second compartment.

[0074] In step 1, the second electrode may be spread on a roller, and the second electrode may be transferred onto the second separator by a roll transfer printing method.

[0075] If the electrode is composed of a p...

Embodiment 1

[0108] 1) In this embodiment, both the first electrode and the second electrode are carbon nanotube films directly grown by the floating catalytic chemical vapor deposition method, and the thickness of the selected film is about 120 nm. Since the area of the film obtained by this method is limited by the size of the growth chamber, for the convenience of spreading, the carbon nanotube film was uniformly cut into 2×4cm 2 , to get multiple small pieces of carbon nanotube thin film; cut another two pieces of 5×15mm 2 Carbon nanotube film strips are ready for use.

[0109] 2) Take two polytetrafluoroethylene rollers (5cm in diameter and 3cm in length), wet the cylindrical surface of each roller with ethanol, and then spread the small pieces of carbon nanotube film end to end on the cylindrical surface of the roller superior. Each roller uses 4 small pieces of carbon nanotube film, and the paving area is 2×15cm 2 .

[0110] If the electrode of the device design needs to be th...

Embodiment 2

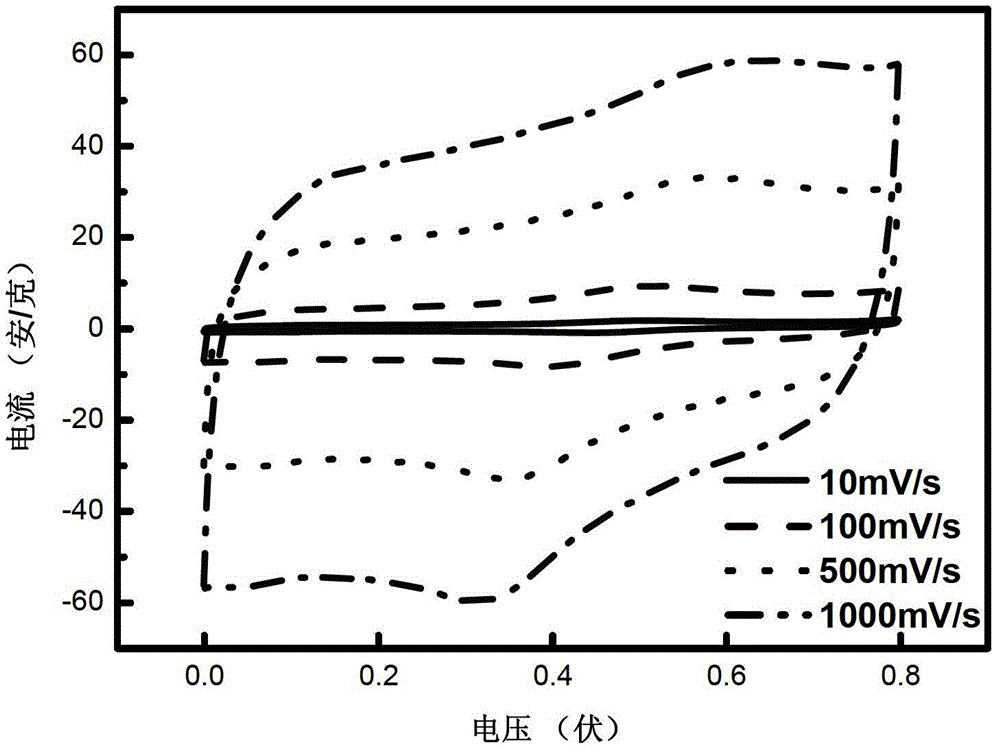

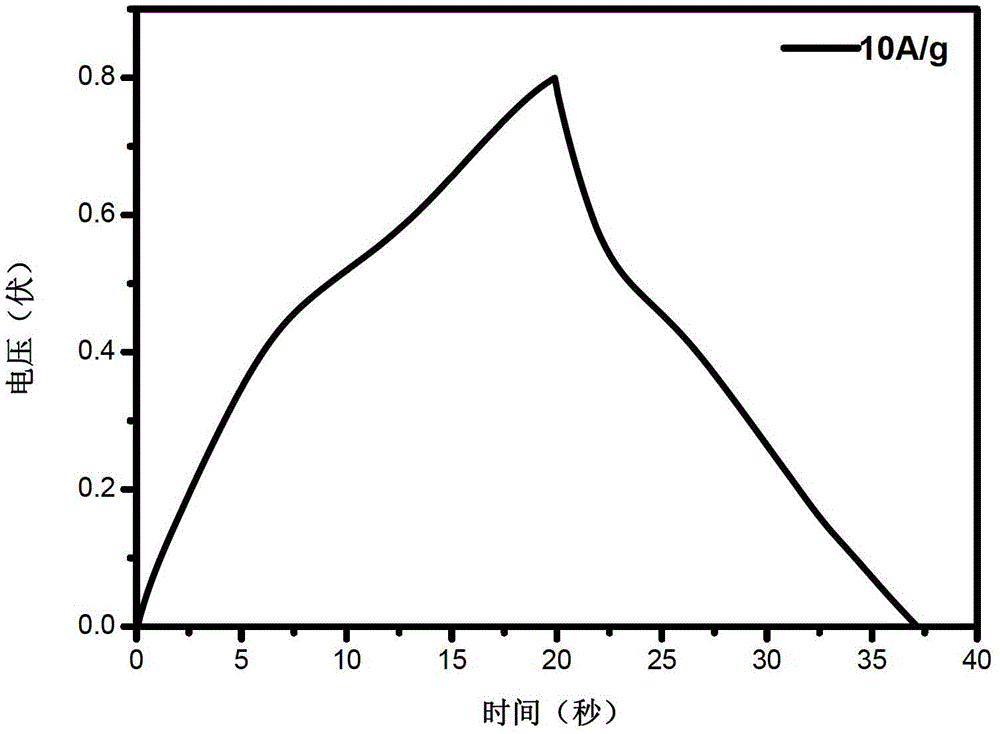

[0120] 1) First, cut the carbon nanotube film directly grown by the floating catalytic chemical vapor deposition method to obtain multiple pieces with an area of 2.5×4.5cm 2 Carbon nanotube thin film slices with a thickness of about 200nm; cut another two pieces of 5×15mm 2Carbon nanotube film strips are ready for use. Then, two small pieces of carbon nanotube film were spread on a hollow polytetrafluoroethylene (PVDF) rectangular frame (2.0×4.0cm 2 ) on both sides; then immerse the carbon nanotube film in an aqueous solution containing 0.1M aniline monomer, 0.25M sulfuric acid, and 0.25M sodium sulfate, and in-situ polymerize polyaniline with a constant potential method, with a potential of 0.8V and a time of 30 seconds; remove the carbon nanotube / polyaniline composite film from the PVDF rectangular frame, cut and retain the composite film in the PVDF frame, and obtain two pieces of 2.0×4.0cm 2 Porous carbon nanotube / polyaniline composite thin film pellets. Repeatedly, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com