Method for fabricating flexible electrode

A flexible electrode and electrochemical technology, applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of low capacity, large weight, and low usage of active materials, and achieve high specific capacity and quality. Light, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

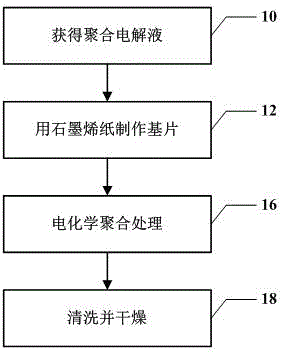

Method used

Image

Examples

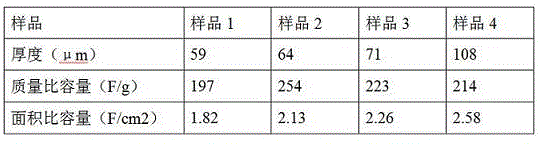

example 1

[0050] (1) Cut the graphene paper size to 30×60mm;

[0051] (2) After the graphene paper was ultrasonically cleaned in acetone and deionized water for 1 h, it was dried with nitrogen for later use;

[0052] (3) Prepare acetonitrile electrolyte, which contains 0.1mol / L lithium perchlorate and 0.2mol / L 3,4-ethylenedioxythiophene monomer;

[0053] (4) Immerse the graphene paper in the electrolyte as the working electrode, the platinum wire as the counter electrode, and the silver / silver chloride as the reference electrode. After soaking for 30 minutes, use the chronopotentiometry to polymerize. The polymerization potential is 0 to 1 volt. The current is 3mA / cm 2 , cycle 100 times, the electrochemical deposition is completed;

[0054] (5) Rinse the electrochemically deposited graphene paper with absolute ethanol for 2 to 5 times, and vacuum-dry it at 60 to 80°C for 10 to 12 hours to obtain the conductive polythiophene flexible electrode sample 1 of the graphene paper.

example 2

[0056] (1) Cut the graphene paper size to 30×60mm;

[0057] (2) After the graphene paper was ultrasonically cleaned in acetone and deionized water for 1 h, it was dried with nitrogen for later use;

[0058] (3) Prepare acetonitrile electrolyte, which contains 0.5mol / L lithium perchlorate and 0.3mol / L 3,4-ethylenedioxythiophene monomer;

[0059] (4) Immerse the graphene paper in the electrolyte as the working electrode, the platinum wire as the counter electrode, and the silver / silver chloride as the reference electrode. After soaking for 30 minutes, use the chronopotentiometry to polymerize. The polymerization potential is 0 to 1 volt. The current is 3mA / cm 2 , cycle 100 times, the electrochemical deposition is completed;

[0060] (5) Rinse the electrochemically deposited graphene paper with absolute ethanol for 2 to 5 times, and vacuum-dry it at 60 to 80°C for 10 to 12 hours to obtain the conductive polythiophene flexible electrode sample 2 of the graphene paper.

example 3

[0062] (1) Cut the graphene paper size to 30×60mm;

[0063] (2) After the graphene paper was ultrasonically cleaned in acetone and deionized water for 1 h, it was dried with nitrogen for later use;

[0064] (3) Prepare acetonitrile electrolyte, which contains 0.1mol / L lithium perchlorate and 0.2mol / L 3,4-ethylenedioxythiophene monomer;

[0065] (4) Immerse the graphene paper in the electrolyte as the working electrode, the platinum wire as the counter electrode, and the silver / silver chloride as the reference electrode. After soaking for 30 minutes, use the chronopotentiometry to polymerize. The polymerization potential is 0 to 1 volt. The current is 8mA / cm 2 , cycle 100 times, the electrochemical deposition is completed;

[0066] (5) Rinse the electrochemically deposited graphene paper with absolute ethanol for 2 to 5 times, and vacuum-dry it at 60 to 80°C for 10 to 12 hours to obtain the conductive polythiophene flexible electrode sample 3 of the graphene paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com