Low temperature catalytic fused salt electrolyte capable of increasing electro-oxidation performance of carbon

A technology of molten salt electrolyte and low-temperature catalysis, which is applied in the field of electrolyte systems, can solve the problems of inability to continuously improve the performance of carbon electro-oxidation, limited performance improvement, and metal shedding, so as to improve the performance of carbon electro-oxidation, improve performance, and easily The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

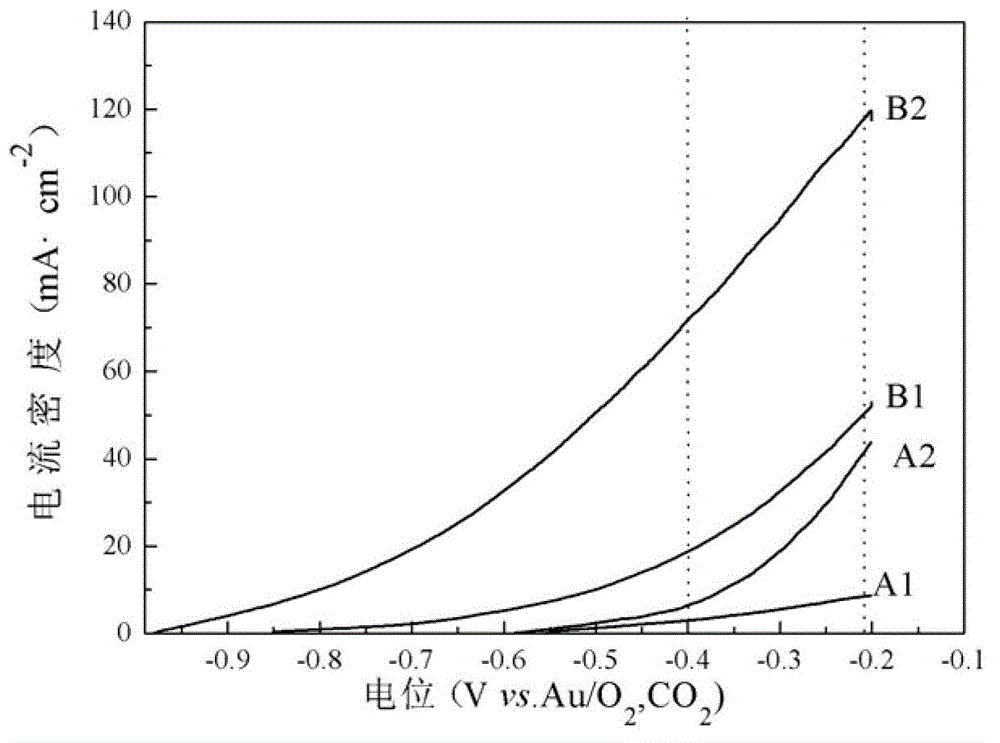

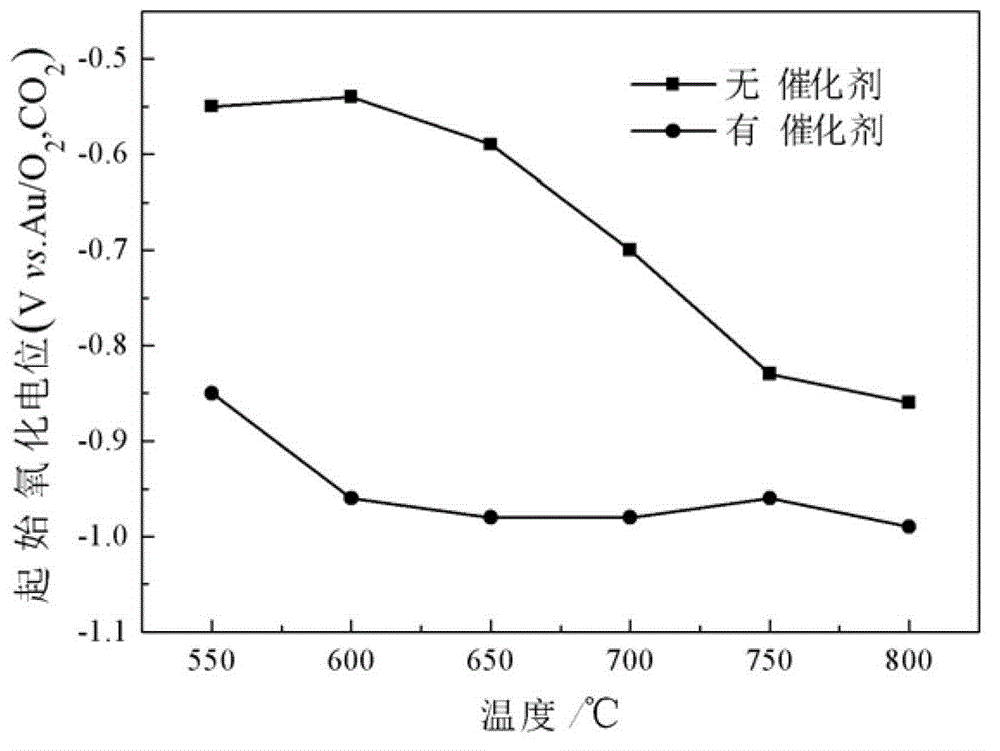

[0022] 20g of CsVO 3 -MoO 3 (molar ratio is 3:1, melting point 377°C) added to 100g of Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (The mass ratio is 32:34:34. At this time, the mixed carbonate has a minimum melting point of 397°C). In the carbonate electrolyte, at 550°C, the conductivity of the electrolyte can be increased from 0.725S·cm -1 Increased to 1.155S·cm -1 .

Embodiment 2

[0024] 10g CsVO 3 -MoO 3 (molar ratio is 3:1) added to 100g of Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (The mass ratio is 32:34:34) in the carbonate electrolyte.

Embodiment 3

[0026] 5g CsVO 3 -MoO 3 (molar ratio is 3:1) added to 100g of Li 2 CO 3 -Na 2 CO 3 -K 2 CO 3 (The mass ratio is 32:34:34) in the carbonate electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Oxidation potential | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com