Sintering method and sintering furnace of zirconium oxide all-ceramic tooth

A sintering method, zirconia technology, applied in fluidized bed furnaces, furnaces, dentures, etc., to achieve the effects of easy mass production, lower production costs, and easy popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

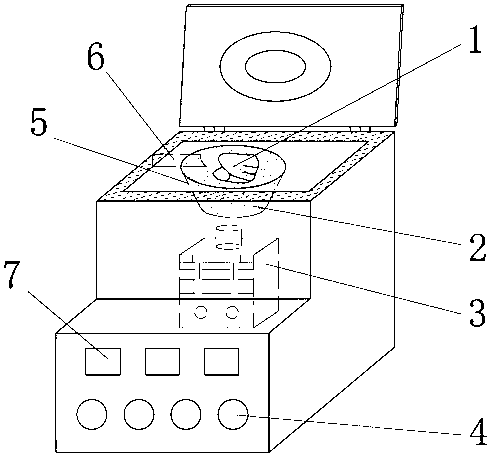

Image

Examples

Embodiment 1

[0019] Use 94% zirconia powder with a purity of 99% or more by weight, add 5% yttrium oxide and alumina as toughening agents and crystal phase stabilizers, and add a small amount of dentin coloring agent. Isostatically press the hydraulic machine for 4 hours, the pressure is 2000kg / cm 2 , The zirconia powder is pressed into a compact.

[0020] Use an ordinary CNC milling machine to process the blank, change the flat end milling cutter of the CNC milling machine to a small ball end milling cutter, enlarge it by 20%, and use special auxiliary software to make crown blanks.

[0021] Put the crown blank into a silicon carbide powder microwave sintering furnace for heating and sintering. When the heating temperature is 1300℃~1500℃, the temperature is accurately controlled to increase in a stepped manner. When the temperature rises to 1350℃, the temperature is kept constant for 20 minutes and rises to 1400℃ When the temperature is constant for 20 minutes, when it rises to 150℃, the tempe...

Embodiment 2

[0024] The basic materials and operating steps used in this example are basically the same as those in Example 1, except that the static pressing time of the hydraulic machine is extended to 6 hours. In addition, the crown blank is glued with a layer of dextrin and sintered at 1700°C before sintering. The zirconia powder that is no longer sintered at 1500°C is crushed once, and then sintered.

[0025] The zirconia all-ceramic teeth sintered in this example are in accordance with the requirements in shape and size, and the size is relatively consistent, the sintering shrinkage can be controlled at 20%, and the zirconia on the surface of the crown does not appear to adhere to silicon carbide powder. Transparency is also better. In addition, increasing the temperature during sintering can increase the transparency of the porcelain teeth, but the brittleness is also large, which can only be applied to certain anterior teeth.

[0026] In addition, for the sintering furnace used during ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com