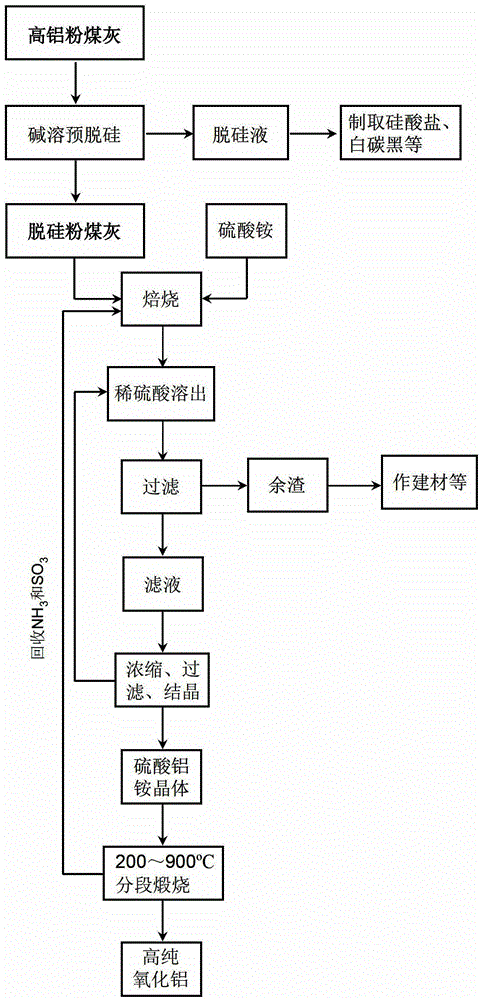

Method for recovering alumina, silica and other metal components from fly ash

A technology of metal composition and silicon dioxide, applied in the direction of alumina/aluminum hydroxide, silicon oxide, etc., can solve the problems of large amount of tailings, high energy consumption, dangerous waste of resources, etc. The effect of short time and high leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Pre-desilication of high-alumina fly ash The composition of high-alumina fly ash from Inner Mongolia Tuoketuo Thermal Power Plant is shown in Table 1.

[0022] Table 1 Chemical composition of high alumina fly ash samples

[0023] Element

Al 2 o 3

SiO 2

total iron oxide

TiO 2

CaO

the sum

Content (%)

48.45

40.55

1.92

1·54

3.64

1·31

97.41

[0024] Take 150 grams of high-alumina fly ash, put it into a 1-liter high-pressure reactor, and then add sodium hydroxide solution (500 ml of water + 180 g of solid sodium hydroxide). After sealing the reaction kettle, start the stirrer, raise the temperature in the reaction kettle to 140° C., and keep the temperature constant for 1.5 hours. After the temperature in the reaction kettle was cooled to below 80°C, the kettle was opened and the reaction mixture was taken out. Filtrate, wash the filter residue twice with hot water (3...

Embodiment 2

[0030] 1. Pre-desilication of high alumina fly ash

[0031] The chemical composition of high aluminum fly ash is the same as in Example 1.

[0032]Take 150 grams of high-alumina fly ash, put it into a 1-liter high-pressure reactor, and then add sodium hydroxide solution (400 ml of water + 90 g of solid sodium hydroxide). After the reactor was sealed, the stirrer was started, and the temperature in the reactor was raised to 200° C., and the temperature was kept constant for 1.5 hours. After the temperature in the reaction kettle was cooled to below 80°C, the kettle was opened and the reaction mixture was taken out. After filtering, the filter residue was washed twice with hot water (200 ml each time) and then dried for later use; the washing solution was filtered and combined with the dissolution filtrate, and the volume was adjusted to 1000 ml. Silicon molybdenum blue was used to measure the concentration of silicon in the desiliconization solution, and the pre-desilication ...

Embodiment 3

[0038] 1. Pre-desilication of high alumina fly ash

[0039] The chemical composition of high aluminum fly ash is the same as in Example 1.

[0040] Take 150 grams of high-alumina fly ash, put it into a 1-liter high-pressure reactor, and then add sodium hydroxide solution (400 ml of water + 100 g of solid sodium hydroxide). After sealing the reaction kettle, start the stirrer, raise the temperature in the reaction kettle to 180° C., and keep the temperature constant for 1.5 hours. After the temperature in the reactor was cooled to below 50°C, the kettle was opened to take out the reaction mixture. After filtering, the filter residue was washed twice with hot water (200 ml each time) and then dried for later use; the washing solution was filtered and combined with the dissolution filtrate, and the volume was adjusted to 1000 ml. Silicon molybdenum blue was used to measure the concentration of silicon in the desiliconization solution, and the pre-desilication efficiency (that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com