Alpha molybdenum oxide nanorod gas sensitive material and preparation method and application thereof

A technology of gas-sensitive materials and molybdenum oxide, which is applied in the fields of molybdenum oxide/molybdenum hydroxide, material resistance, nanotechnology, etc., to achieve the effects of low experimental temperature, simple equipment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Accurately weigh 0.3g of ammonium molybdate and add it into 5ml of deionized water, and fully dissolve it by electromagnetic stirring. Slowly drop 20ml of concentrated nitric acid under the condition of electromagnetic stirring. After stirring evenly, the Erlenmeyer flask was placed in a water bath with magnetic stirring, and stirred at 85°C for 0.5h. After the stirring was stopped, the temperature was continued at 85°C for 1h. After the reaction, the obtained white precipitate was centrifuged and washed twice with deionized water, then once with absolute ethanol, and the obtained powder was dried in an oven at 60°C for 12 hours to obtain nano-oxidized Molybdenum powder.

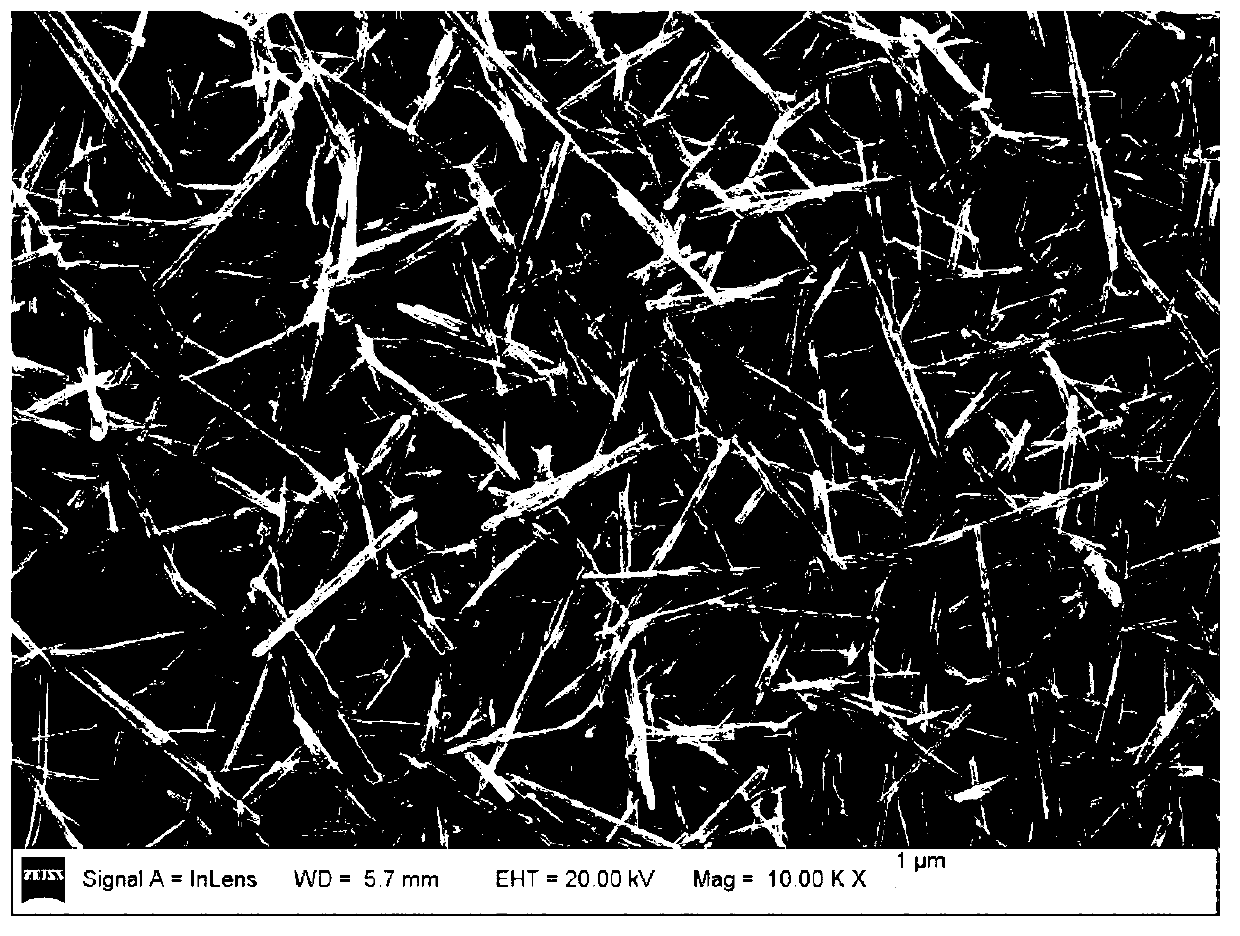

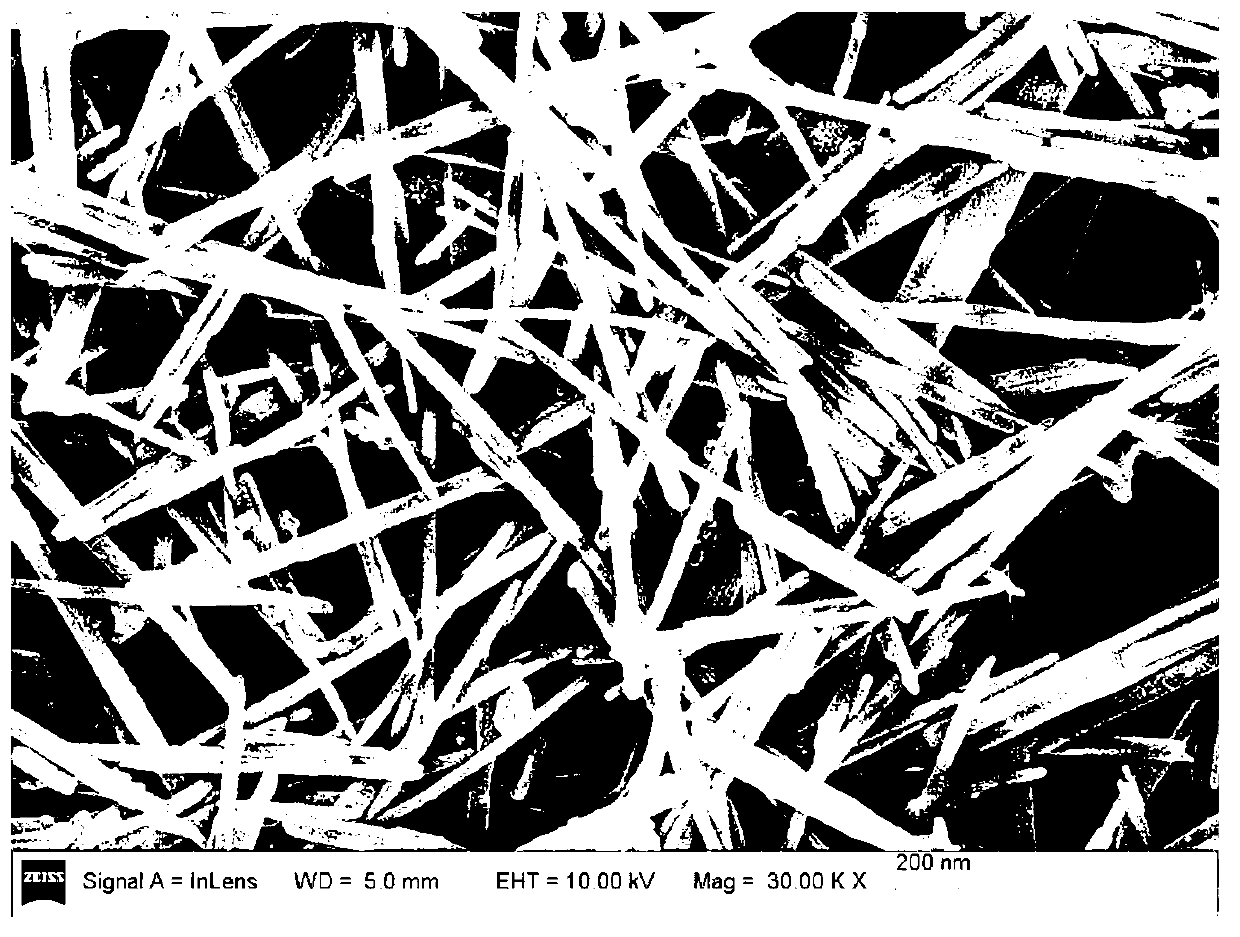

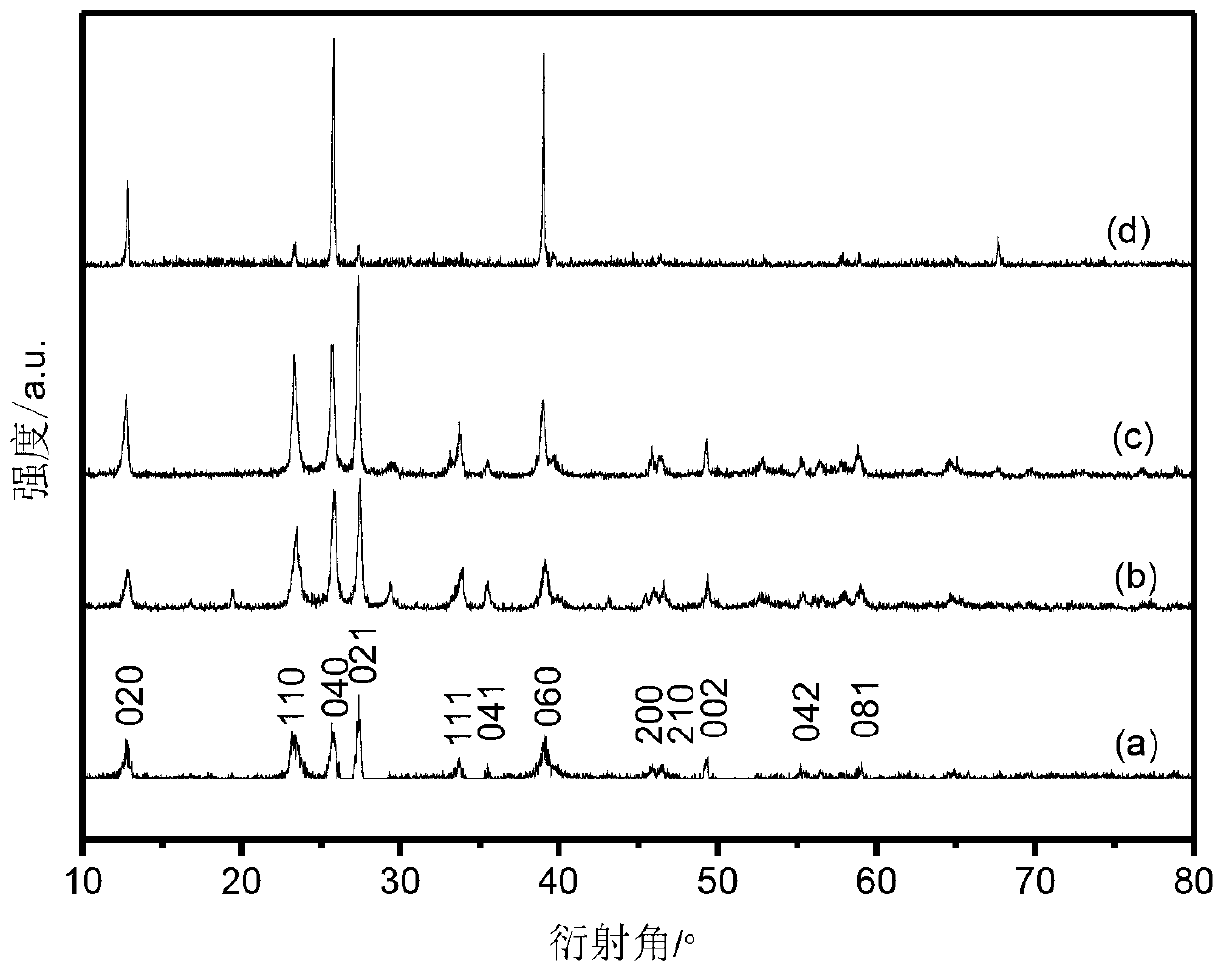

[0031] The scanning electron microscopy results of the figure 1 and figure 2 , the diameter of molybdenum oxide nanorods is 30-60nm, and the length is 1.5-2.0μm; the XRD analysis results of the prepared molybdenum oxide powder are shown in image 3 , the obtained product is an orthorhombic molybd...

Embodiment 2

[0033] Accurately weigh 0.3g of ammonium molybdate and add it into 5ml of deionized water, and fully dissolve it by electromagnetic stirring. Slowly drop 15ml of concentrated nitric acid under the condition of electromagnetic stirring. After stirring evenly, the Erlenmeyer flask was placed in a water bath with magnetic stirring, and stirred for 1 h at 80 ° C. After the stirring was stopped, it was continued to insulate at 80 ° C for 1.5 h. After the reaction, the obtained white precipitate was centrifuged and washed in the same manner as in Example 1, and the obtained powder was dried in a 60° C. oven for 12 hours to obtain nanometer molybdenum oxide powder.

Embodiment 3

[0035] Accurately weigh 0.5g of ammonium molybdate and add it into 5ml of deionized water, and fully dissolve it by electromagnetic stirring. Slowly drop 20ml of concentrated nitric acid under the condition of electromagnetic stirring. After stirring evenly, the Erlenmeyer flask was placed in a water bath with magnetic stirring, and stirred at 85°C for 0.5h. After the stirring was stopped, the temperature was continued at 85°C for 1h. After the reaction, the obtained white precipitate was centrifuged and washed in the same manner as in Example 1, and the obtained powder was dried in a 60° C. oven for 12 hours to obtain nanometer molybdenum oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com