Process for continuously producing dimethyl adipate through reaction-rectification method

A technology of dimethyl adipate and rectification method, which is applied in the field of continuous production of dimethyl adipate by reaction-rectification method, can solve the problems of low acid conversion rate, high energy consumption, low production capacity and the like, and achieves conversion High efficiency, simple production process and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

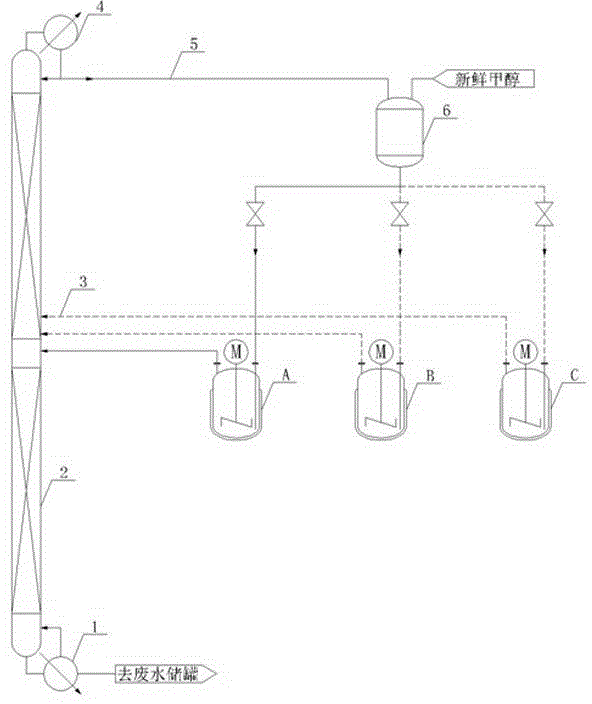

[0017] A kind of new process of producing dimethyl adipate of the present invention adopts a rectifying tower to be equipped with three reaction kettles to be concretely implemented, and the raw material of every kettle is 2.1kg methanol, 2.6kg adipic acid, 0.2kg catalyst; The reaction kettle adopts low pressure Steam heating, heating temperature 105°C; steam is introduced from the middle and upper part of the rectification tower; the bottom of the rectification tower is also heated by low-pressure steam, and the heating temperature is 130°C; an appropriate amount of distilled water is added to the bottom of the rectification tower in advance; the top of the tower is condensed with condensate ; The reflux ratio is 4. Operate according to the three-pot operation method mentioned above. After stabilization, the acid values of each pot after 8 hours of de-alcoholization of the pot liquid are all less than 10.

Embodiment 2

[0019] A kind of new process of producing dimethyl adipate of the present invention adopts a rectifying tower to be equipped with three reaction stills to be concretely implemented, and the raw material of every still is 4.2kg methanol, 2.6kg adipic acid, 0.4kg catalyst; The reaction still adopts low pressure Steam heating, heating temperature 105°C; steam is introduced from the middle and upper part of the rectification tower; the bottom of the rectification tower is also heated by low-pressure steam, and the heating temperature is 130°C; an appropriate amount of distilled water is added to the bottom of the rectification tower in advance; the top of the tower is condensed with condensate ; The reflux ratio is 5. Operate according to the operation mode of three kettles. After stabilization, the acid values of each kettle are less than 10 after 6 hours of dealcoholization of the kettle liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com