Lithium-ion battery composite positive electrode as well as preparation method and application thereof

A lithium-ion battery and composite positive electrode technology, which is applied in battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of not using industrial production, low energy density, moisture sensitivity, etc., to improve energy density and stability , Improve specific capacity and cycle performance, improve the effect of interface problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

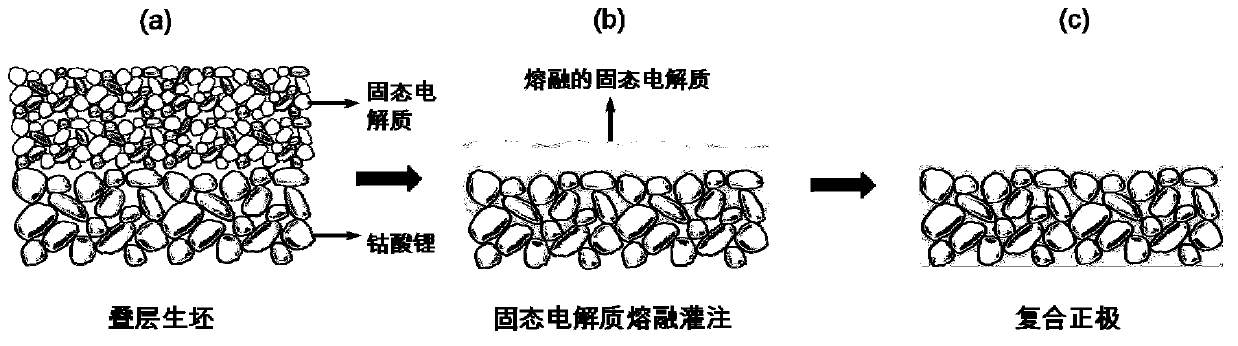

[0033] Embodiment 1, preparation lithium-ion battery composite cathode

[0034] (1) Preparation of the positive active material green body: commercialized lithium cobaltate powder (average particle size 6 microns), ball milled for 24 hours, dried at 80°C for 8 hours, and weighed 1g of the dried positive active material Pressed into a green body.

[0035] (2) Preparation of inorganic solid electrolyte green body: put lithium metaborate and lithium fluoride (mass ratio 2:1) in a mortar and grind and mix for 5 minutes, weigh 0.5g of the ground inorganic solid electrolyte and press it into a green body .

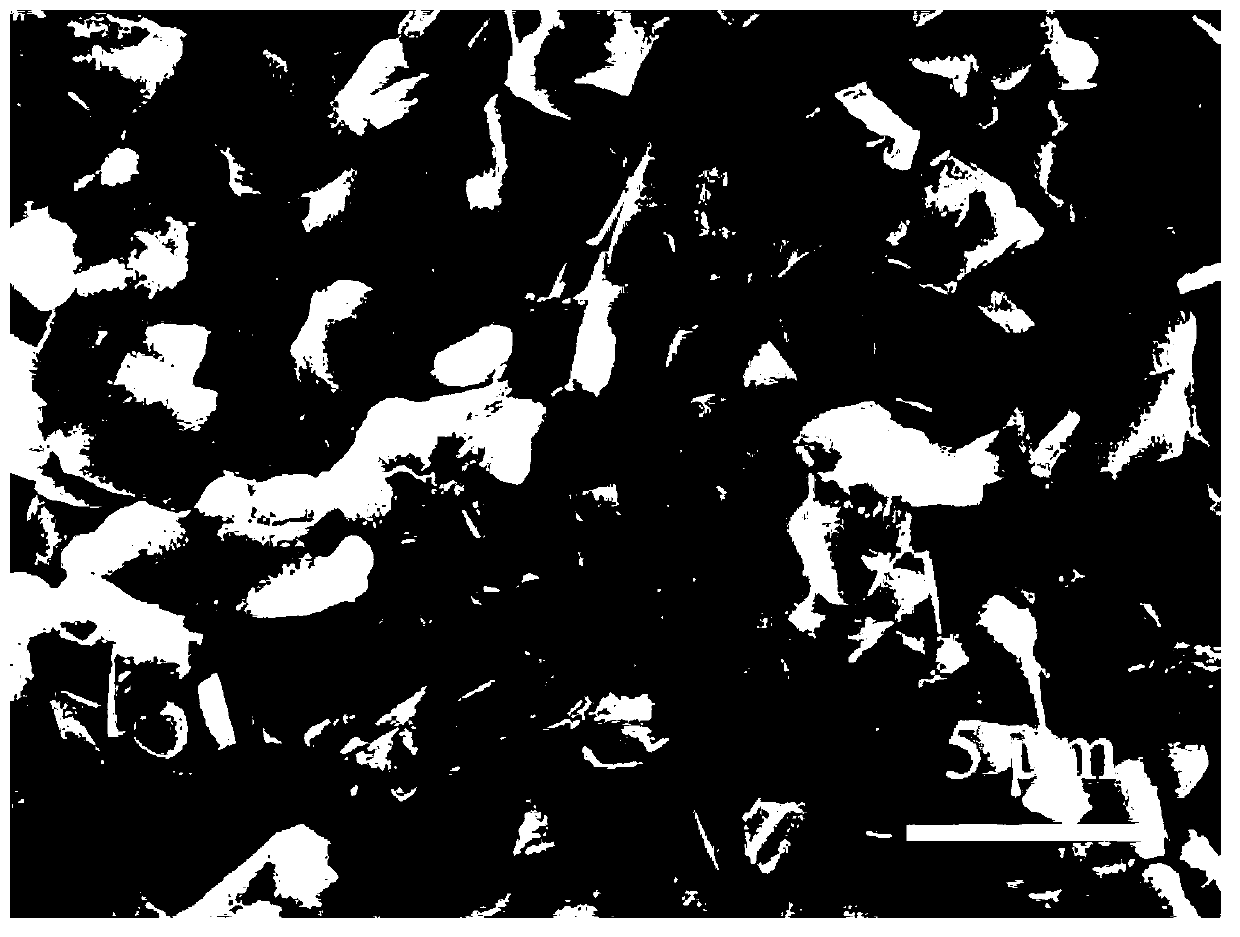

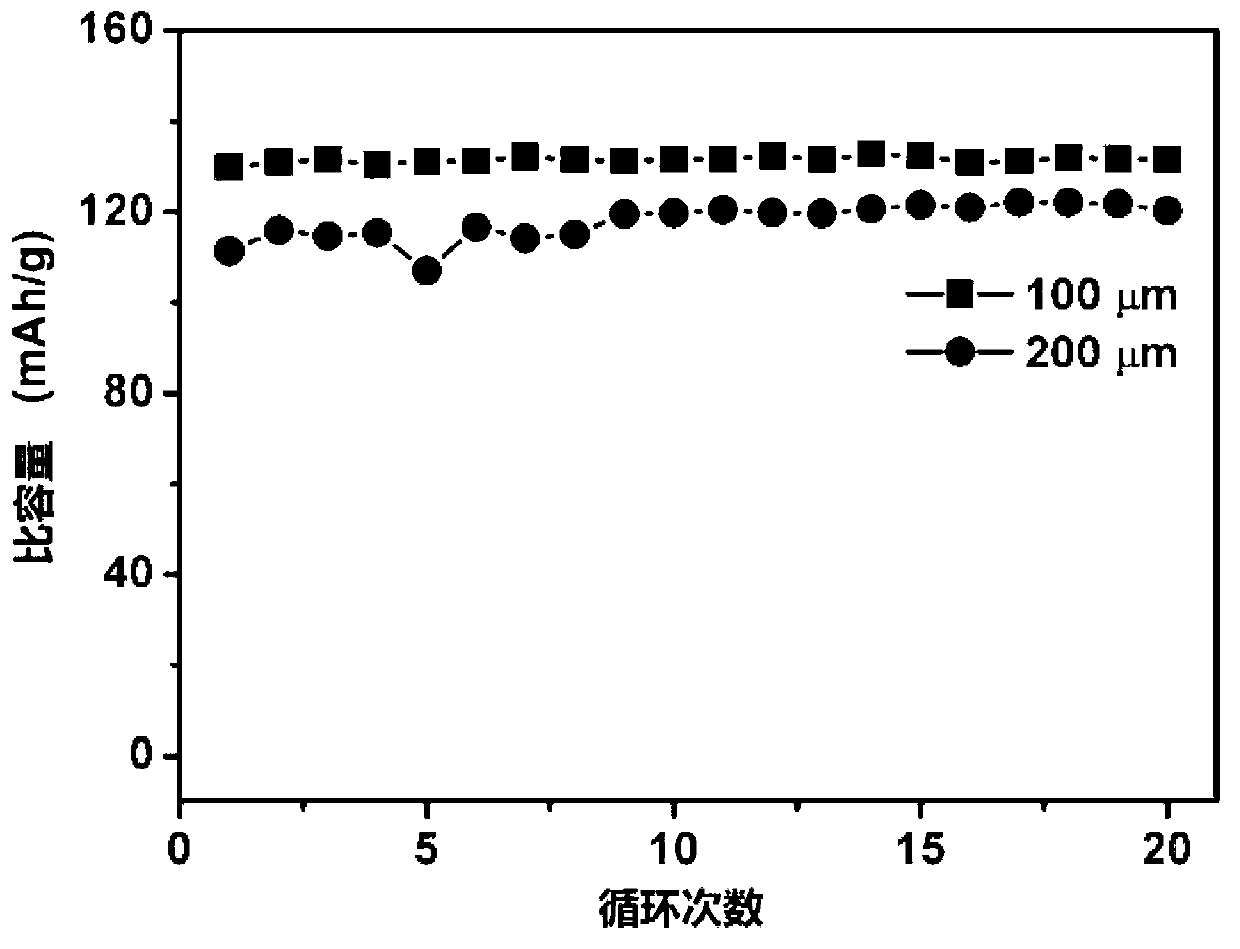

[0036] (3) Sintering of the composite positive electrode: the inorganic solid electrolyte green body is placed on the positive electrode active material green body to be laminated, and sintered at 900 ° C for 1 hour to obtain a composite positive electrode, which is ground to a thickness of 100 microns with sandpaper.

[0037] The composite positive electrode is composed of a ...

Embodiment 2

[0038] Embodiment 2, preparation lithium ion battery composite cathode

[0039] (1) Preparation of positive active material green body: commercialized lithium manganate powder (average particle size 11 microns), ball milled for 2 hours, dried at 70°C for 12 hours, weighed 1g of dried positive active material and pressed into a green body.

[0040] (2) Preparation of inorganic solid electrolyte green body: Lithium borate was ground and mixed in a mortar for 10 minutes, and 1 g of ground inorganic solid electrolyte was weighed and pressed into a green body.

[0041] (3) Sintering of the composite positive electrode: the inorganic solid electrolyte green body is placed on top of the positive electrode active material green body and laminated, and sintered at 700 ° C for 0.5 hours to obtain a composite positive electrode, which is ground to a thickness of 500 microns with sandpaper.

[0042] The composite positive electrode is composed of a three-dimensional skeleton structure fo...

Embodiment 3

[0043] Embodiment 3, preparation lithium ion battery composite cathode

[0044] (1) Preparation of the positive active material green body: commercialized lithium iron phosphate powder (average particle size 3 microns) was ball milled for 12 hours, dried at 60°C for 10 hours, and 1.9 g of the dried positive active material was weighed and pressed into a green body.

[0045] (2) Preparation of the inorganic solid electrolyte green body: Lithium fluoride was ground and mixed in a mortar for 8 minutes, and 0.1 g of the ground inorganic solid electrolyte was weighed and pressed into a green body.

[0046] (3) Sintering of the composite positive electrode: the inorganic solid electrolyte green body is placed on top of the positive electrode active material green body and laminated, and sintered at 1100 ° C for 10 hours to obtain a composite positive electrode, which is ground to a thickness of 1000 microns with sandpaper.

[0047] The composite positive electrode is composed of a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com