Wastewater treatment agent, preparation method thereof and wastewater treatment method

A wastewater treatment agent and wastewater technology, which is applied in the directions of oxidized water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex process, poor treatment effect, and difficult control of the treatment process, and achieve good treatment effect and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention also provides a preparation method of the above-mentioned wastewater treatment agent, which comprises uniformly mixing sodium silicate and ferrate to obtain ferrosilicon copolymer, and mixing hydrogen peroxide and ferrous sulfate to obtain Fenton's reagent.

[0029] The wastewater treatment agent of the present invention is prepared by preparing ferrosilicon copolymer and Fenton's reagent respectively, and is added to wastewater for treatment when used.

[0030] According to the wastewater treatment agent provided by the present invention, in order to better remove ammonia nitrogen and COD in wastewater, preferably, the ferrosilicon copolymer is formed by the polymerization of sodium silicate and ferrate; the sodium silicate and ferrate The molar ratio of salt is 3:1-3. The Fenton reagent includes H 2 o 2 and FeSO 4 ·7H 2 O; the H 2 o 2 with FeSO 4 ·7H 2 The molar ratio of O is 10:1-3.

[0031] According to the wastewater treatment agent provided ...

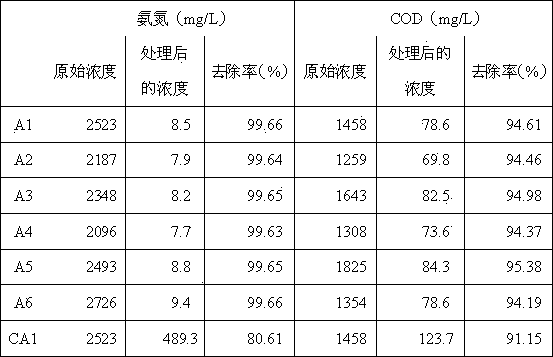

Embodiment 1

[0038] Wastewater treatment: High ammonia nitrogen and high COD wastewater is produced during the production of hydrazine hydrate. The water quality is pH 12, COD 1458mg / L, ammonia nitrogen 2523mg / L, and water temperature 60°C.

[0039] Preparation of waste water treatment agent by weight: ferrosilicon copolymer 55wt%, sodium silicate (as Na 2 SiO 3 In terms of) and ferrate (in K 2 FeO 4 Calculated) the molar ratio is 3:3; Fenton's reagent 45wt%, hydrogen peroxide (with 100% H 2 o 2 Calculated) and ferrous sulfate (as FeSO 4 ·7H 2 O) The molar ratio is 10:1.

[0040] First add acid to the wastewater to adjust the pH value to 6, and then add the wastewater treatment agent to the wastewater. The amount of the wastewater treatment agent added is: the amount of the wastewater treatment agent added to 1L of wastewater is 0.9kg, stirred and mixed, and the reaction time is After 80 minutes, the treated wastewater A1 was obtained.

Embodiment 2

[0042] Wastewater treatment: High ammonia nitrogen and high COD wastewater is produced during the production of hydrazine hydrate. The water quality is pH 12.5, COD 1259mg / L, ammonia nitrogen 2187mg / L, and water temperature 60°C.

[0043] Preparation of waste water treatment agent by weight: ferrosilicon copolymer 55wt%, sodium silicate (as Na 2 SiO 3 In terms of) and ferrate (in K 2 FeO 4 The molar ratio of the meter) is 3:1; Fenton's reagent 45wt%, hydrogen peroxide (with 100% H 2 o 2 Calculated) and ferrous sulfate (as FeSO 4 ·7H 2 O meter) the molar ratio is 10:3.

[0044] First add acid to the wastewater to adjust the pH value to 7, and then add the wastewater treatment agent to the wastewater. The amount of the wastewater treatment agent added is: the amount of the wastewater treatment agent added to 1L of wastewater is 0.6kg, stirred and mixed, and the reaction time is After 60 minutes, the treated wastewater A2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com