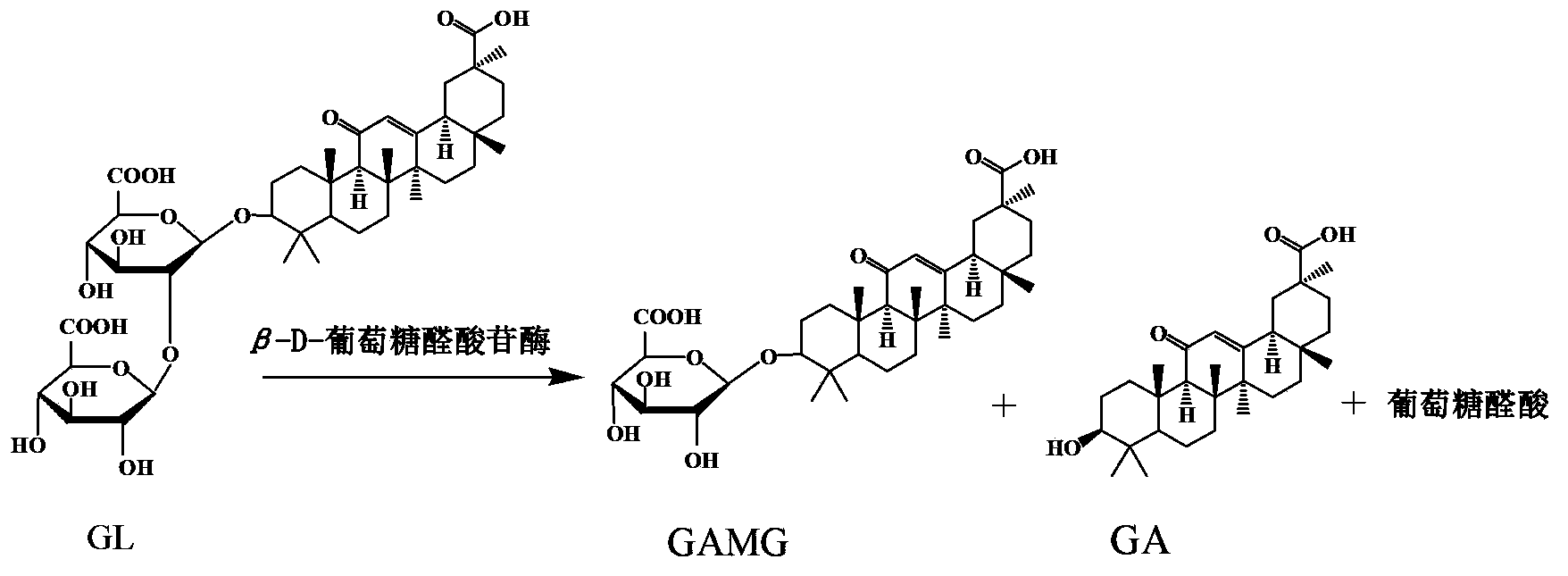

Method for preparing glycyrrhetinic acid monoglucuronide

A technology of glycyrrhetinic acid and glucose, applied in the direction of microbial-based methods, biochemical equipment and methods, bulk chemical production, etc., can solve the problems that GAMG cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

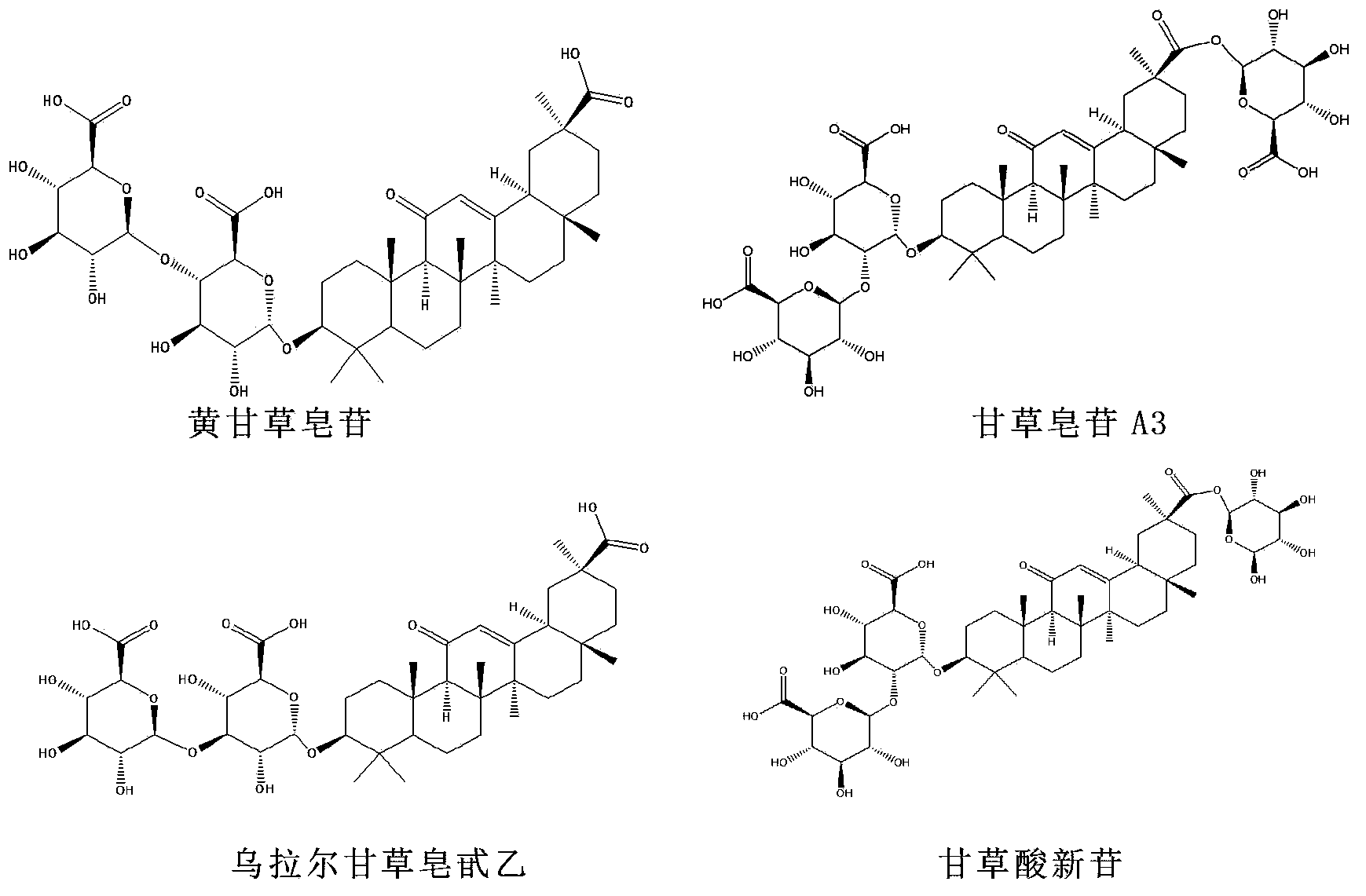

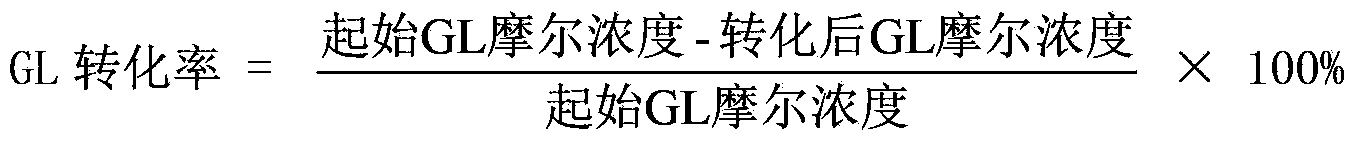

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, only using glycyrrhizic acid monoammonium salt as inducer to produce enzyme implementation method:

[0044] Inoculate the Penicillium purpurea Li-3 strain on the slant medium, and cultivate it at a constant temperature of 30°C for 3 days. The composition of the slant medium is: glucose 0.5g, NH 4 NO 3 0.3g, KH 2 PO 4 0.1g, KCl0.05g, MgSO 4 ·7H 2 O0.05g, FeSO 4 ·7H 2 O0.001g, distilled water 100mL, agar 1.5g, adjust the pH to 5.5, sterilize at 121°C for 20min, and cool to room temperature.

[0045] Take the spores on the slant medium, inoculate them into the seed medium, and culture them on a shaker at 30°C at 170r / min for 72h, then transfer 5% of the inoculum into the secondary seed medium at 30°C on a shaker at 170r / min Cultivate for 24 hours to obtain secondary seed liquid, the composition of the seed medium is: glucose 0.5g, NH 4 NO 3 0.3g, KH 2 PO 4 0.1g, KCl0.05g, MgSO 4 ·7H 2 O0.05g, FeSO 4 ·7H 2 O0.001g, 100mL of distilled water, adju...

Embodiment 2

[0047] Example 2, the implementation method of adding exogenous accelerator to produce enzymes of monoammonium glycyrrhizinate:

[0048] Slope culture and seed culture are the same as in Example 1.

[0049] The secondary seed solution was inserted into the enzyme-producing medium according to the inoculation amount of 10% by volume, and the fermented liquid reached the maximum specific enzyme activity of 82.3U / ml (whole cell enzyme activity) for 72 hours at 30°C and 170r / min shaker culture , wherein the conversion rate of GL reached 93.6%, and the yield of GAMG reached 92.7%. The composition of the enzyme production medium: monoammonium glycyrrhizinate 0.6g, licorice total extract 0.4g, NH 4 NO 3 0.3g, KH 2 PO 4 0.1g, KCl0.05g, MgSO 4 ·7H 2 O0.05g, FeSO4 ·7H 2 O0.001g, 100mL of distilled water, adjust the pH to 5.5, sterilize at 121°C for 20min, and cool to room temperature.

Embodiment 3

[0051] Slope culture and seed culture are the same as in Example 1.

[0052] The secondary seed liquid was inserted into the enzyme-producing medium according to the inoculum amount of 10% by volume, and cultivated on a shaker at 30°C and 170r / min for 72 hours. Enzyme solution 100mL, specific enzyme activity is 141477U / ml (enzyme activity of broken cell crude enzyme solution). Composition of enzyme production medium: 1.2g monoammonium glycyrrhizinate, 0.8g total extract of licorice, NH 4 NO 3 0.6g, KH 2 PO 4 0.2g, KCl0.1g, MgSO 4 ·7H 2 O0.1g, FeSO 4 ·7H 2 O0.002g, distilled water 200mL, pH4.8, after sterilizing at 121°C for 20min, cool to room temperature.

[0053] Take a 1000mL Erlenmeyer flask with 400mL of substrate solution inside, add 100mL of crude enzyme solution of broken cells to the transformation system, culture on a shaker at 30°C for 6 hours, centrifuge, and take the supernatant for detection by high performance liquid chromatography , the conversion rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com