Productive propylene fluidized catalytic cracking (FCC) catalyst and preparation method thereof

A catalytic cracking and catalyst technology, applied in physical/chemical process catalysts, hydrocarbon cracking to hydrocarbons, molecular sieve catalysts, etc., can solve the problem of low propylene selectivity, no attention to the influence of molecular sieve pore structure product selectivity, and increase propylene yield And other problems, to achieve the effect of good propylene selectivity, good industrial application prospects, low yield of dry gas and coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

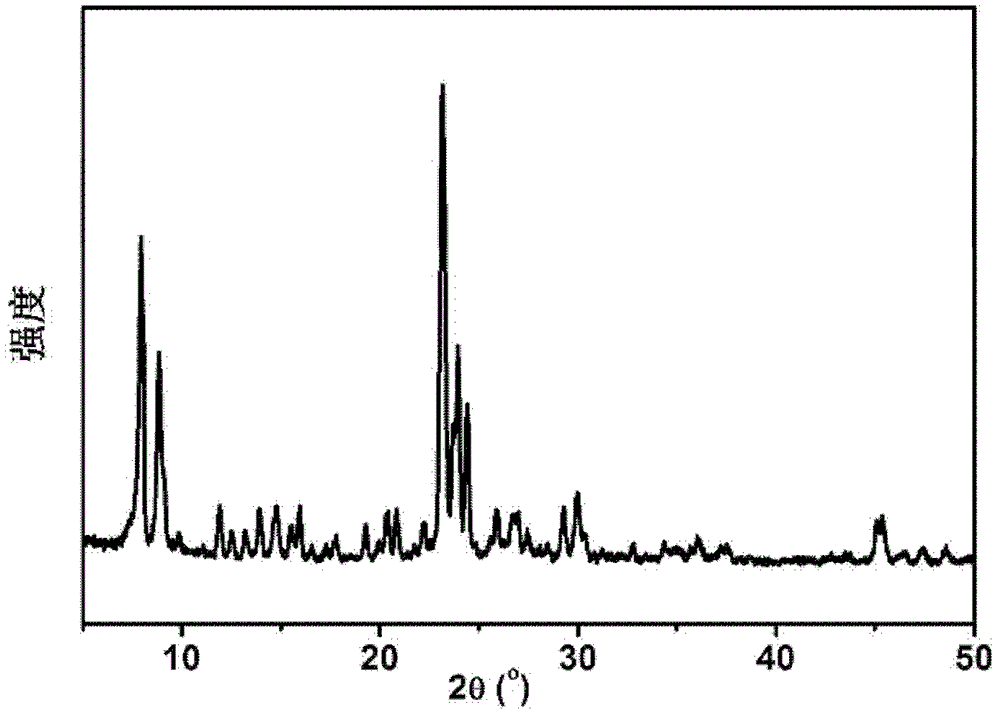

[0036] This embodiment provides a ZSM-5 molecular sieve with hierarchical pore structure, which is prepared according to the following steps:

[0037] Add 5 g of activated retort earth to 400 g of 0.2 M hydrochloric acid solution, place in a water bath at 70°C and stir rapidly for 4 hours to obtain a mixture;

[0038] Add 170g of deionized water, 8.9g of tetrapropylammonium bromide (TPABr) and 129g of water glass to the above mixture in turn, and stir rapidly for 5min;

[0039] Adjust the pH value of the mixture to 10 with a sulfuric acid solution until it becomes a gel state to obtain a reactant gel;

[0040] Then the temperature of the water bath was raised to 80°C, and the gel was aged for 8 hours;

[0041] Then the aged gel was transferred to a 1L autoclave for hydrothermal crystallization at 170°C for 48 hours;

[0042] After the crystallization is completed, the purified product is cooled, filtered, washed, and then placed in an oven to dry at 120°C for 4-8 hours, and ...

Embodiment 2

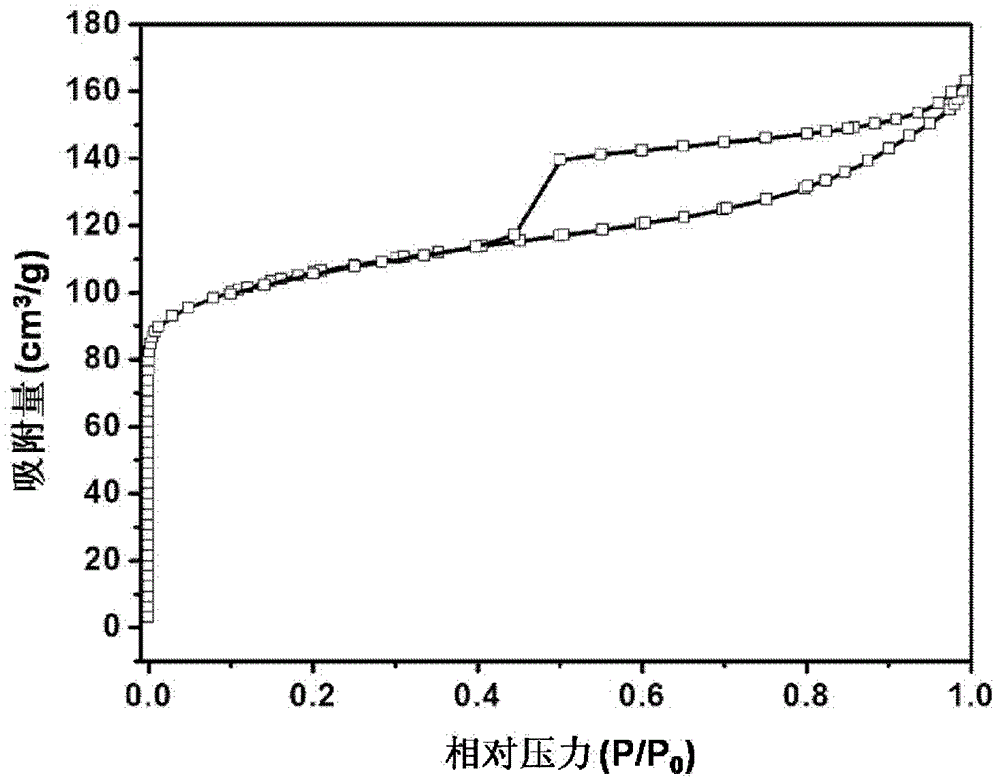

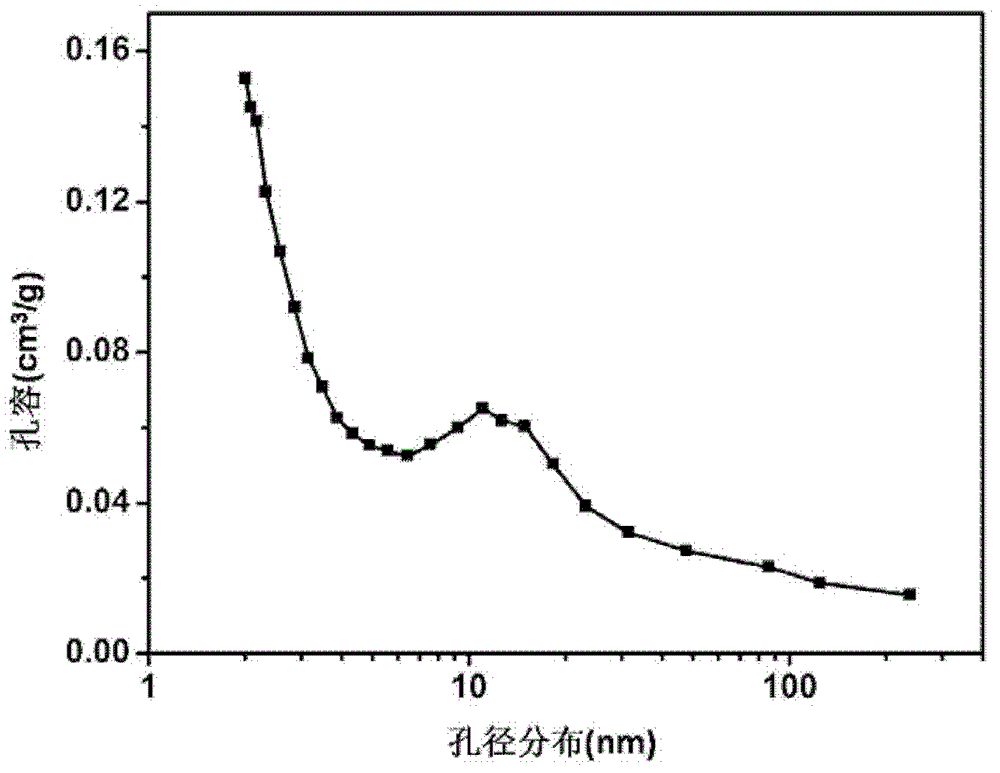

[0045] This example provides a ZSM-5 molecular sieve with hierarchical pore structure, which is prepared according to the method in Example 1. The difference is that in this example, the rectorite calcination temperature is 750°C, and the calcination time is 4h. The reaction The pH value of the product gel is 11, the aging temperature of the reactant gel is 75 ° C, and the aging time is 10 h. The obtained product is marked as B, and its mesopore volume is 0.18 cm 3 / g, the micropore volume is 0.076cm 3 / g, the mesopore volume is 2.37 times that of the micropore volume, and the mesopore diameter is 6-20nm.

Embodiment 3

[0047] This example provides a ZSM-5 molecular sieve with hierarchical pore structure, which is prepared according to the method in Example 1. The difference is that in this example, the rectorite calcination temperature is 950°C, and the calcination time is 2h. The reaction The pH value of the product gel is 11, and the aging time of the reactant gel is 24h. The resulting product is denoted as C, and its mesopore volume is 0.16cm 3 / g, the micropore volume is 0.073cm 3 / g, the mesopore volume is 2.18 times that of the micropore volume, and the mesopore diameter is 5-19nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com