Cellophane positive flotation collector and preparation method of cellophane positive flotation collector

A positive flotation, collector technology, applied in flotation, solid separation and other directions, can solve the problems of oleic acid being difficult to dissolve and disperse, high temperature requirements, and poor oleic acid pertinence, etc., to achieve excellent flotation. The effect of indicators, low production costs, and broad industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation of chlorinated oleic acid in the present invention refers to the patent chlorinated fatty acid sodium / potassium salt flotation agent and its preparation method, the patent number is ZL200810197935.8.

[0025] Haikou A3 mine, raw ore grade P 2 o 5 20.48%, MgO 0.58%, SiO 2 is 44.86%, and CaO is 20.39%. For this kind of minerals, the main task of beneficiation is to desiliconize, and the forward flotation process is commonly used in industry, and the positive selection will enrich the dolomite in the concentrate to a certain extent, so the experiment plans to use the positive selection or the forward-reverse flotation process , to ensure that the MgO content is below 1%, and achieve the purpose of effectively separating impurity minerals such as collophosite and quartz. With traditional fatty acid collectors, only P 2 o 5 The grade increased by 3 percentage points, so the positive flotation collector should choose collophosite positive flotation collec...

Embodiment 1

[0027] Ingredients: 35kg chlorinated oleic acid, 35kg stearic acid, 25kg linoleic acid and 5kg sodium hydroxide;

[0028] Add water to the reaction kettle, heat and stir, add stearic acid and heat up to 60-80°C, then add sodium hydroxide aqueous solution and stir evenly, then continue to add linoleic acid and chlorooleic acid, heat up to 130-150°C and stir for 2.5-3.5 After about an hour, a brown-black paste-like object is obtained, that is, the collector is obtained.

Embodiment 2

[0030] Ingredients: 45kg chlorooleic acid, 35kg palmitic acid, 10kg coconut oil and 10kg potassium hydroxide;

[0031] Add water to the reaction kettle, heat and stir, add palmitic acid and heat up to 80°C, then add potassium hydroxide aqueous solution and stir evenly, then continue to add coconut oil and chlorooleic acid, heat up to 150°C and stir for about 3.5 hours to obtain a brown-black paste , that is, the collector

[0032] Haikou A3 collophanite is carried out to positive flotation with the novel glenite positive flotation collector prepared in example 1 and embodiment 2. The method of positive flotation adds Na 2 CO 3 adjust p H value and inhibition of Ca 2+ , Mg 2+ , Na 2 SiO 3 Inhibit SiO 2 , (NaPO 4 ) 6 Various metals are suppressed, and then the positive flotation collector involved in the present invention is added to float the useful collophanite.

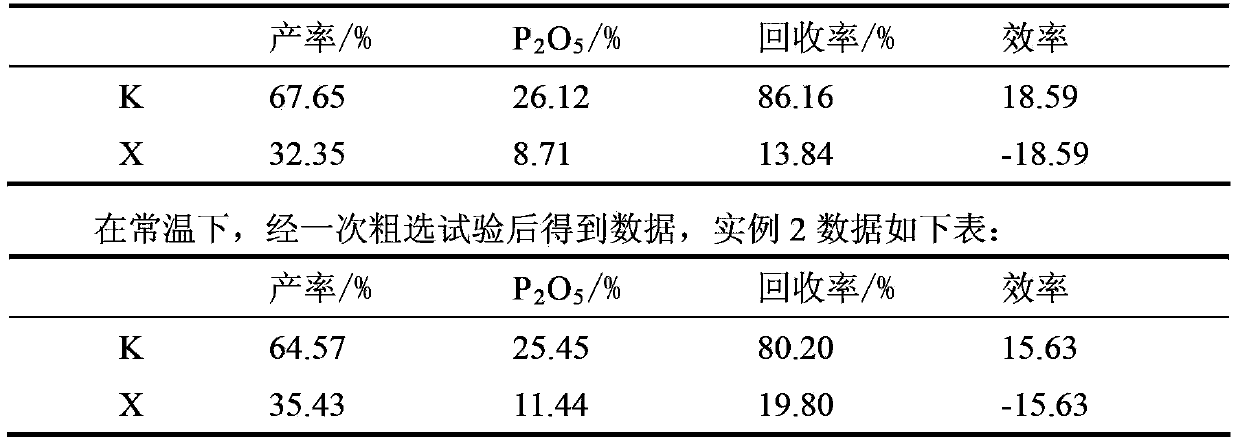

[0033] Under normal temperature, obtain data after a roughing test, example 1 data is as follows:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com