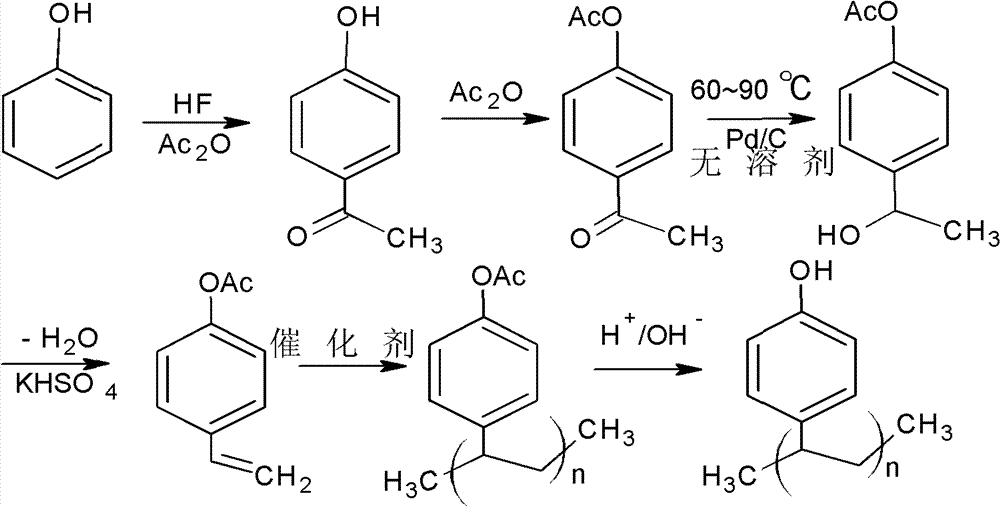

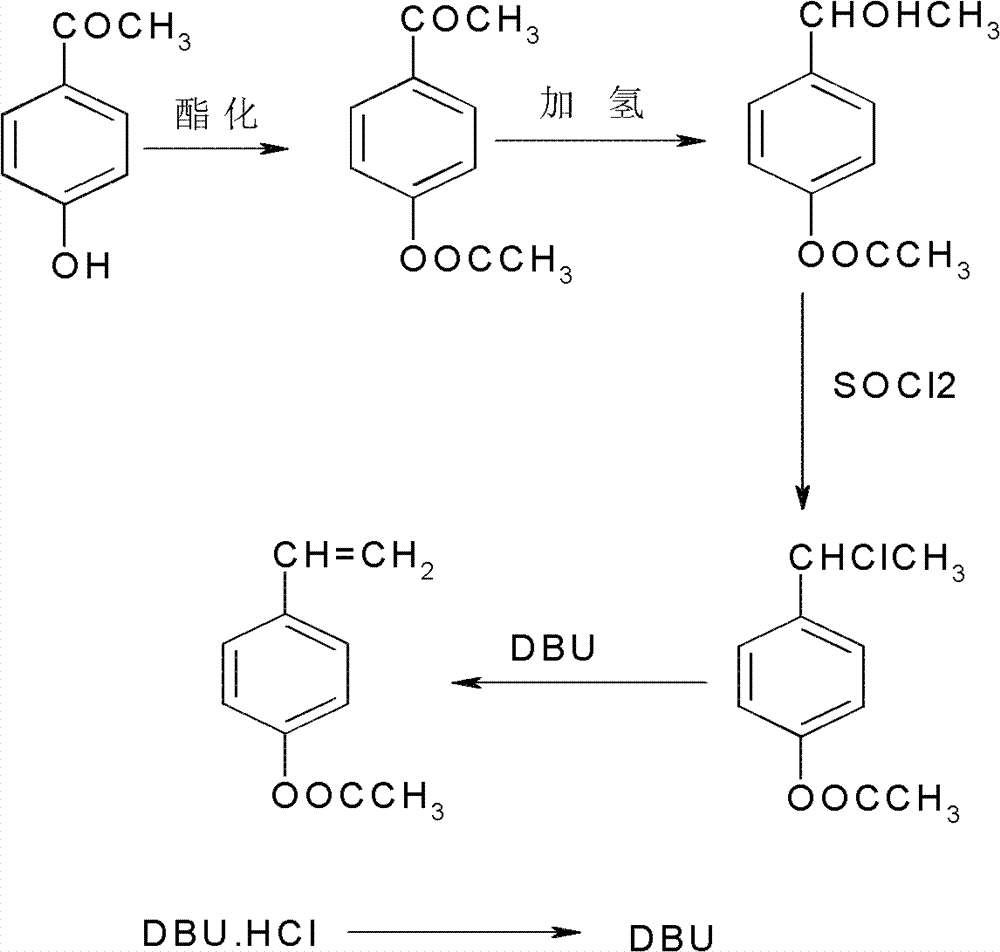

Preparation methods of acetate alpha-phenethyl alcohol and acetate styrene

A technology of acetoxyacetophenone and phenethyl alcohol, applied in the field of preparation of benzene ring derivatives, can solve the problems of increasing solvent separation and recovery procedures, low reaction selectivity and conversion rate, difficulty in separation and purification of dehydration products, etc. The effect of improving the property, reducing the content, and inhibiting the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The test is carried out in a 500ml high-pressure reactor with stirring, 178g p-acetoxyacetophenone, 0.28g sodium hydroxide and 14g palladium / carbon catalyst (containing 5% palladium) are packed in the reactor, and then with 1.2MPa The hydrogen replaces the air in the reactor twice. Keep the hydrogen pressure in the reactor at 1.2 MPa, stir and heat. The reaction temperature was 75° C., and after 6 hours, the hydrogen gas was discharged, and the reaction was completed. Analyze the reaction solution composition with gas chromatography, the result shows, p-acetoxy group α-phenethyl alcohol content is 96.5%, p-acetoxy ethylbenzene 0.5%, unreacted p-acetoxy acetophenone 0.4%, ethylbenzene 1.1%, the rest for other components. The conversion of p-acetoxyacetophenone was 99.7%.

Embodiment 2

[0054] 215g p-acetoxyacetophenone, 0.6g sodium hydroxide and 2.15g palladium / carbon catalyst (containing 5% palladium) are packed in the reactor of 500ml with stirring, then in the hydrogen displacement reactor with 1.5MPa of air twice. Keep the hydrogen pressure in the reactor at 1.5 MPa, and heat the material in the reactor to 90° C., and discharge the hydrogen after reacting for 4 hours. The product is analyzed by gas chromatography, and the results show that the p-acetoxy α-phenylethanol content is 97%, p-acetoxy ethylbenzene 0.4%, unreacted p-acetoxy acetophenone 0.9%, ethylbenzene 1.0%, and the rest is other components. The conversion rate of p-acetoxyacetophenone was 99.1%.

Embodiment 3

[0056] 267g p-acetoxyacetophenone, 1.3g diethanolamine and 16g palladium / carbon catalyst (containing 5% palladium) are packed in the 500ml reactor with stirring, then use the hydrogen displacement reactor of 1.5MPa Second-rate. Keep the hydrogen pressure in the reactor at 1.5 MPa, and heat the material in the reactor to 80° C., and discharge the hydrogen after reacting for 6 hours. The product is analyzed by gas chromatography, and the results show that the p-acetoxy α-phenylethanol content is 96%, p-acetoxy ethylbenzene 1.2%, unreacted p-acetoxy acetophenone 0.7%, ethylbenzene 0.7%, and the rest is other components. The conversion of p-acetoxyacetophenone was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com