Positive ion-free radical mixed photopolymerisable lithographic plate printing plate material based on vinylpyrrolidone copolymer resin

A vinylpyrrolidone, lithographic printing plate technology, applied in the field of photosensitive lithographic printing plate materials, can solve problems such as reduced developability, and achieve the effects of high storage stability, little influence of humidity, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

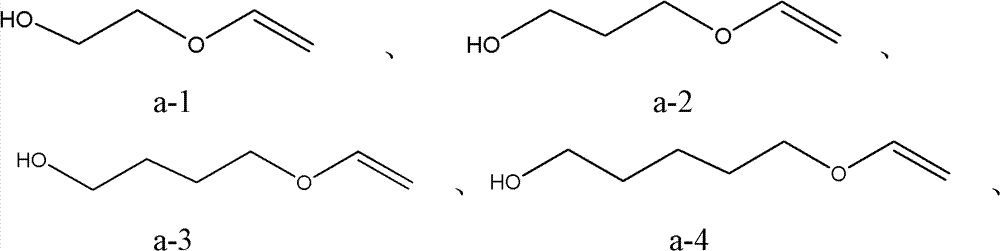

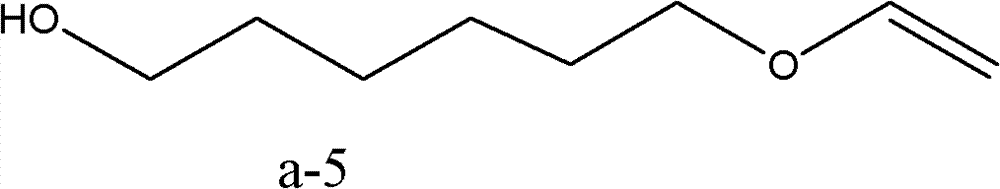

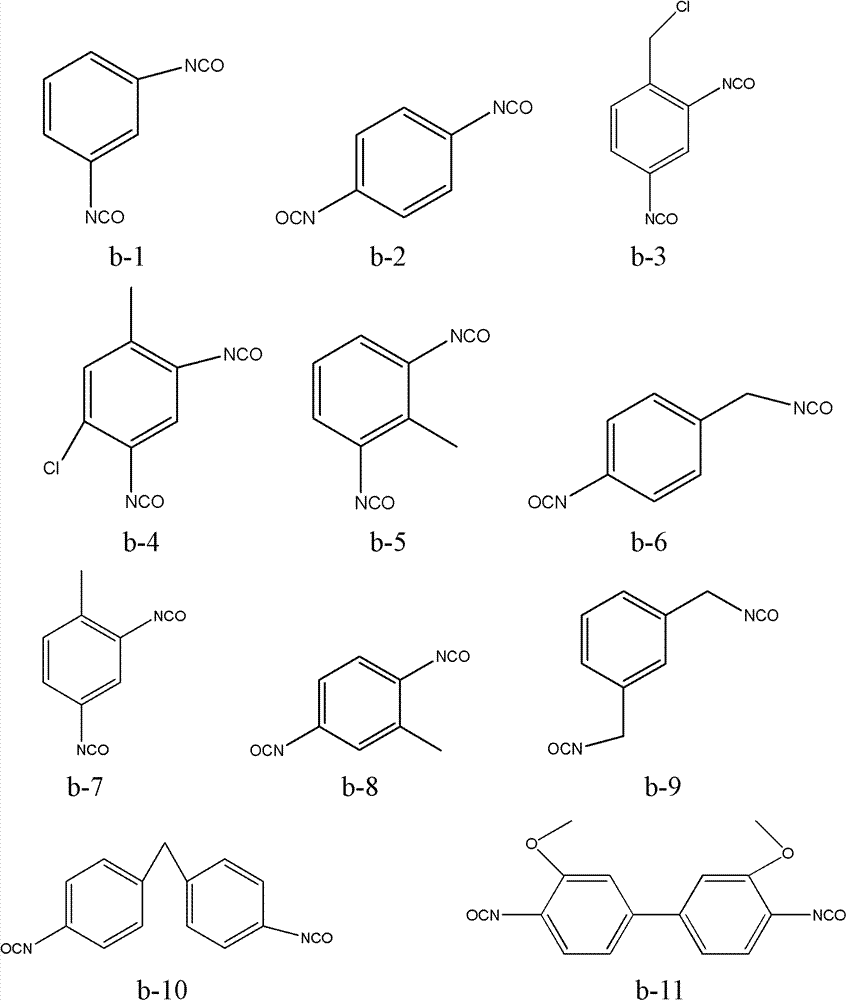

[0113] Synthesis examples 1-7 of hybrid photosensitive compounds that can be hybridized and polymerized, and comparative examples 1-3 of compounds that cannot be hybridized and polymerized

[0114] Examples 1-7 (corresponding to compounds D1-D7), under ice-bath conditions, feed nitrogen into a three-neck flask equipped with electric stirring, constant pressure dropping funnel, and thermometer, add raw material (b) diisocyanate compound, slowly drop Add raw material (a) a vinyl ether compound with hydroxyl groups in the molecule, continue to stir for 1 hour after the dropwise addition, raise the temperature to a constant temperature of 25°C, add a catalytic amount of dibutyltin dilaurate catalyst, slowly drop under vigorous stirring Add raw material (c) a methacrylate compound with a hydroxyl group in the molecule or an acrylate compound with a hydroxyl group in the molecule, raise the temperature to 60°C after the dropwise addition, and stir at a constant temperature for two ho...

Embodiment 1~15

[0120] In a four-neck flask equipped with a stirrer, a condenser, a nitrogen conduit, and a thermometer, add N-vinylpyrrolidone monomer (NVP) and monomers containing ethylenically unsaturated double bonds at room temperature, and the solvent is absolute ethanol. Under nitrogen protection, stir and add the initiator azobisisobutyronitrile (AIBN), the initiator accounts for 0.1% to 0.5% of the total mass of NVP and monomers containing ethylenically unsaturated double bonds, preferably 0.2% to 0.3%, After the initiator is completely dissolved, the temperature of the reaction system is raised to 65-70°C and the reaction is stirred at a constant temperature, and NVP is continuously added dropwise as the reaction progresses, so that the molar ratio of NVP in the system is always maintained at the initial feeding ratio. After the reaction, the solvent was distilled off under reduced pressure to obtain a water-soluble N-vinylpyrrolidone copolymer resin. The synthesis situation of water-...

Embodiment 1

[0126] Example 1: Take 25g of the F2 resin described in Table 2, 15g of the D1 hybrid type photosensitive compound that can be hybridized in Table 1, 7g of reactive diluent isobutyl vinyl ether, 4g of 2-hydroxypropyl acrylate, and initiate Agent A1-11g, ITX1g, sensitizing pigment (B1-5) 0.5g, co-sensitizer (C1) 0.5g, acid brilliant blue 2g, acetone 300g; first dissolve F2 resin in acetone, stir to make it completely dissolved Then add other components, and then filter with 10 μm, 5 μm, and 0.5 μm pore size filter elements in sequence to obtain the photosensitive layer coating solution Example 1 containing a hybrid photosensitive compound that can be hybridized and polymerized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com