Diffusion process of crystalline silicon solar cell

A solar cell and diffusion process technology, applied in crystal growth, diffusion/doping, circuits, etc., can solve the problems of impurity replacement in unfavorable crystalline silicon, affect the conversion efficiency of cells, and damage the surface of silicon chips, so as to reduce the ventilation process Time, improve conversion efficiency, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

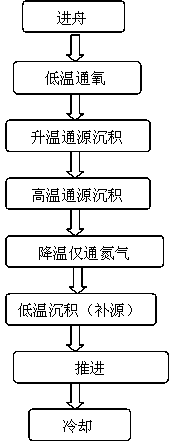

[0016] Such as figure 1 As shown, in the present invention, the silicon wafer is loaded into a quartz boat, and the first step of diffusion is performed: (1) first, 200 mL / min of O 2, And the temperature was raised to 810°C, and the temperature was kept constant for 8.3 minutes, so that the surface of the silicon wafer and O 2 The reaction forms a SiO2 oxide layer; (2) continue to heat up to 845°C, and then pass in POCl with a flow rate of 800mL / min 3 O with a flow rate of 200mL / min 2 and 15000mL / min of N 2 , took 4 minutes; (3) Keep the temperature at 845°C, and continue to feed POCl with a flow rate of 800mL / min 3 O with a flow rate of 200mL / min 2 and 15000mL / min of N 2 , and keep it for 6.7 minutes; the second step of diffusion: (1) reduce the temperature to 825°C, and only feed the N with a flow rate of 15000mL / min 2 , took 3 minutes; (2) Keep the temperature at 825°C, and feed POCl with a flow rate of 800Ml / Min 3 , O with a flow rate of 200mL / min 2 and N with a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com