Composite deck coated with anticorrosive paint

A composite deck and anti-corrosion technology, applied in the direction of hull deck, coating, anti-corrosion coating, etc., can solve the problems of easy pulverization, poor weather resistance, poor impact resistance, etc., achieve low price, excellent adhesion, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

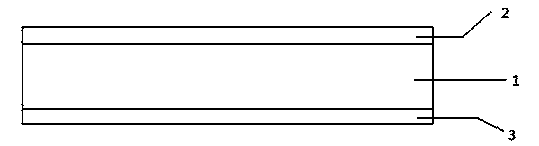

[0013] like figure 1 As shown, a composite deck coated with corrosion-resistant paint is composed of steel plates, and the upper and lower layers of the outer layer of the steel plate 1 are coated with a deck coating 2 and a wear-resistant coating 3 respectively.

[0014] In the composite deck coated with corrosion-resistant paint, the deck coating is composed of hydroxyl internal alkene resin, polyether polyol, alkene resin, defoamer, leveling agent, pigments and fillers; the wear-resistant coating is made of aluminum oxide Composed of ceramic powder, silicon micropowder, carbon black, polyacrylate copolymer solution, and anhydrous xylene.

[0015] The composite deck coated with corrosion-resistant paint and the elastic polyurethane coating used on ships adopt high-pressure airless spraying and other coating methods to form a wear-resistant and anti-corrosion coating engineering system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com