Novel method of coking residual ammoniacal liquor deamination, dephenolization, denitrification and utilization

A technology of coking residual ammonia water and a new method, which is applied in the field of coking residual ammonia water treatment, can solve the problems of high water consumption, large ammonia vapor liquid, high content of phenol and organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

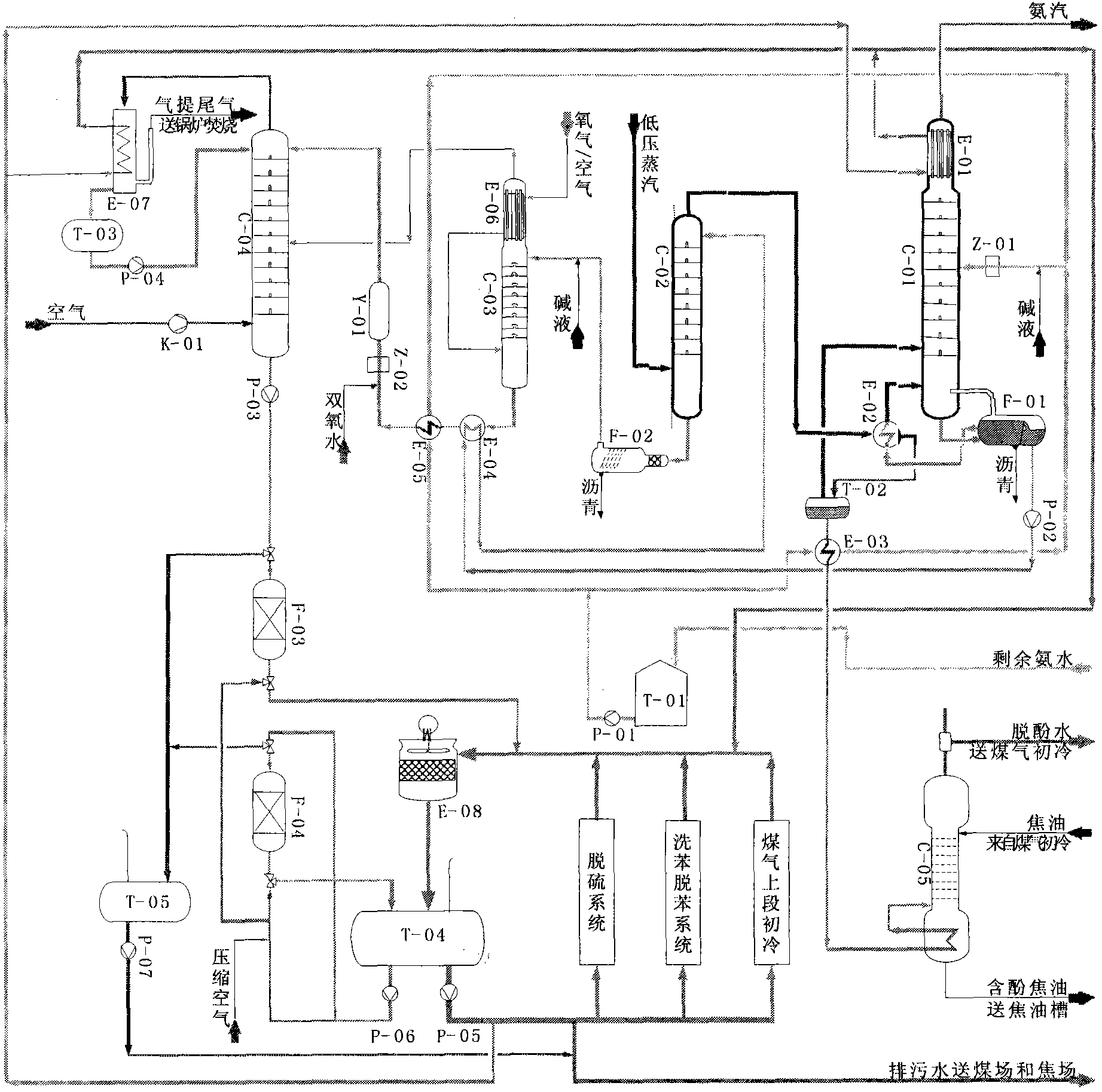

Image

Examples

Embodiment Construction

[0019] The five processes are described in detail as follows:

[0020] Ammonia distillation and deacidification: the lower temperature coking residual ammonia water from the initial gas cooling section passes through E-05 and E-03 in parallel, firstly with the higher temperature oxidation gas stripping water from the first heat exchanger of E-04 oxidation water And the concentrated phenol water from T-02 is connected in parallel for heat exchange, then add an appropriate amount of caustic soda, and through the control of Z-01 ultrasonic wave, send it to the C-01 atmospheric pressure ammonia distillation tower for ammonia distillation and deacidification. The energy required is from C The phenol-containing steam of -02 pressurized dephenolization tower is provided by indirect heating through the E-02 ammonia distillation reboiler. The steam containing H2S, HCN, CO2 and NH3 that escapes from the top of the C-01 ammonia distillation tower is concentrated by the E-01 dephlegmator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com