Barium titanate/polymer composite material with high dielectric constant and its preparation method

A technology of high dielectric constant and composite materials, which is applied in the field of high dielectric, can solve the problems of inorganic particle agglomeration, poor compatibility, and limited performance of composite materials, and achieve enhanced interface interaction, improved dielectric properties, and low dielectric properties. The effect of electrical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

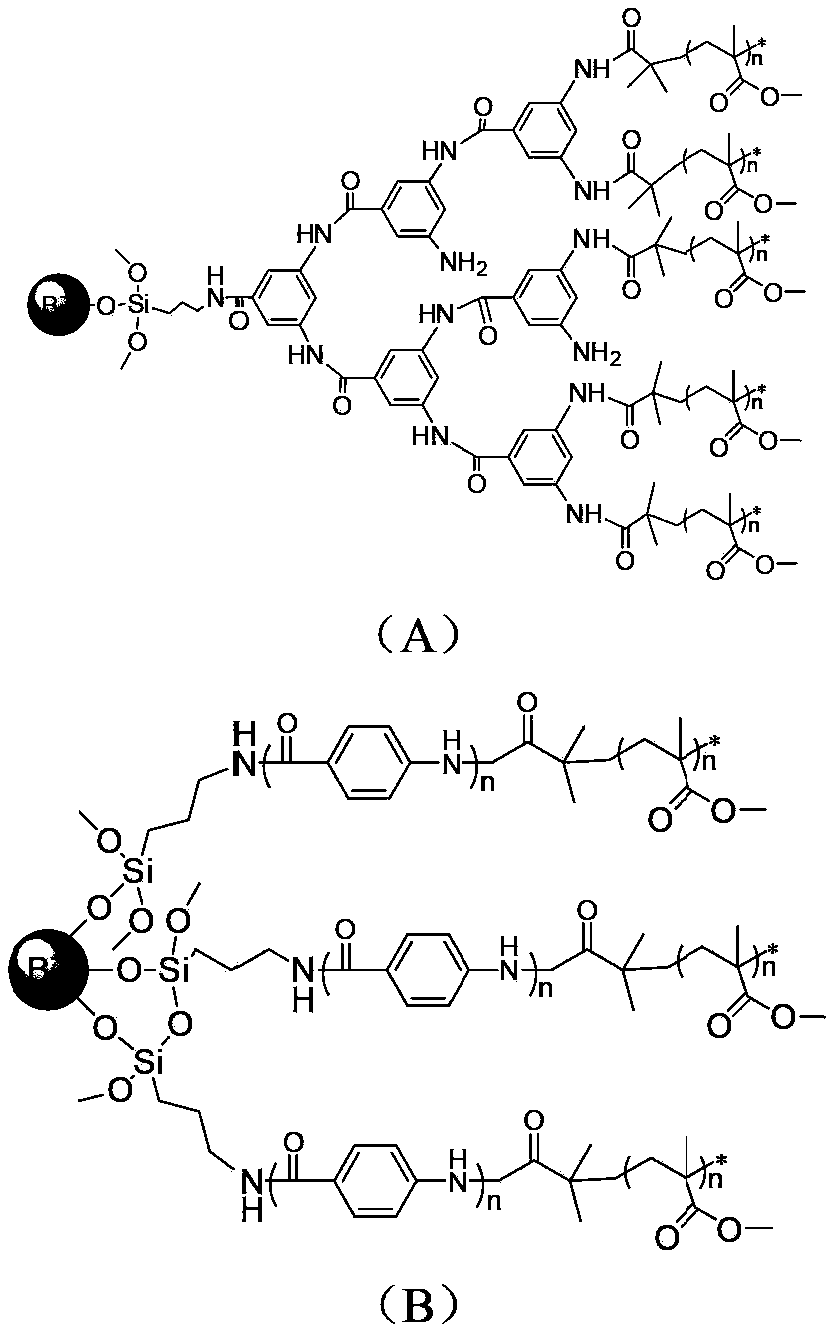

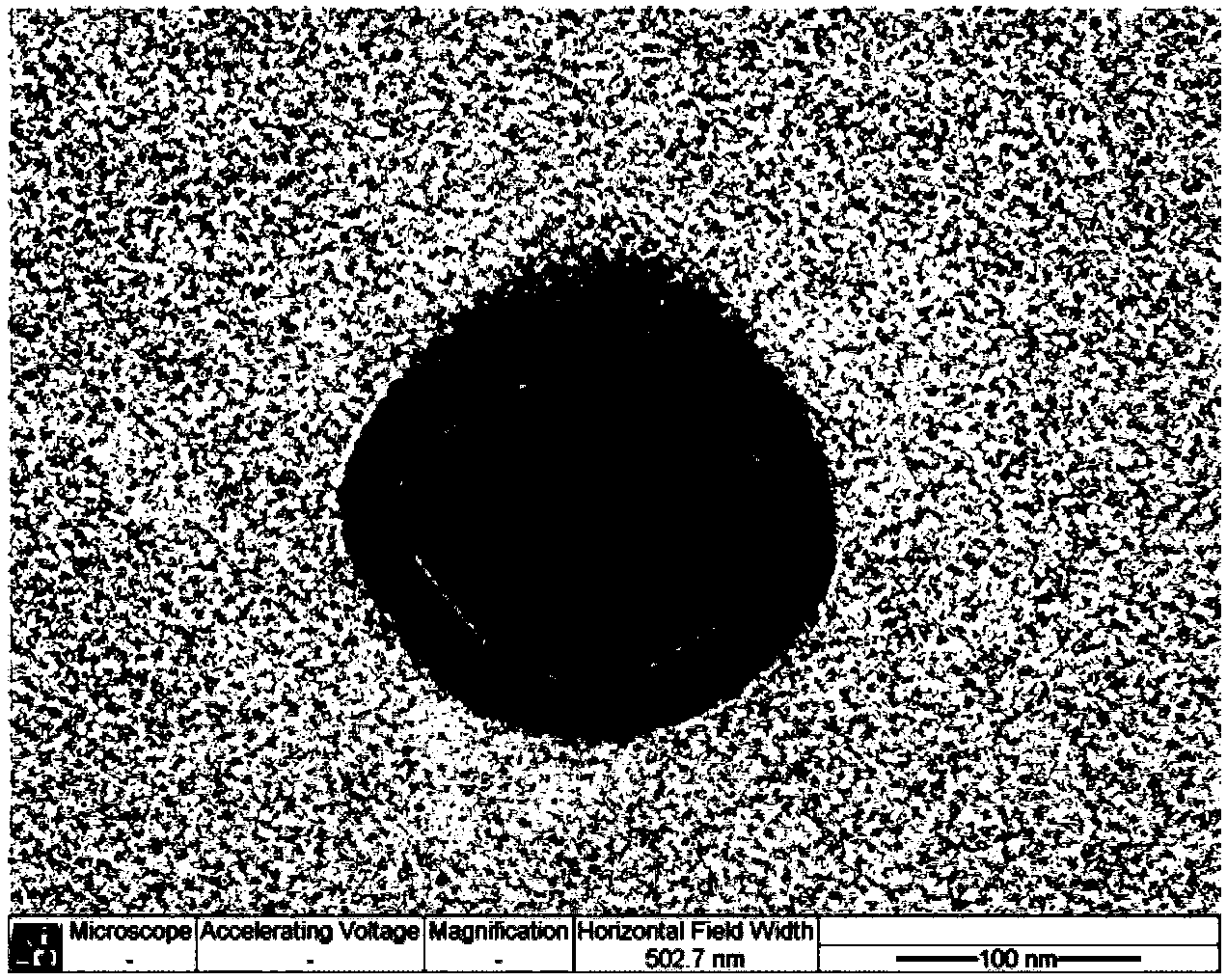

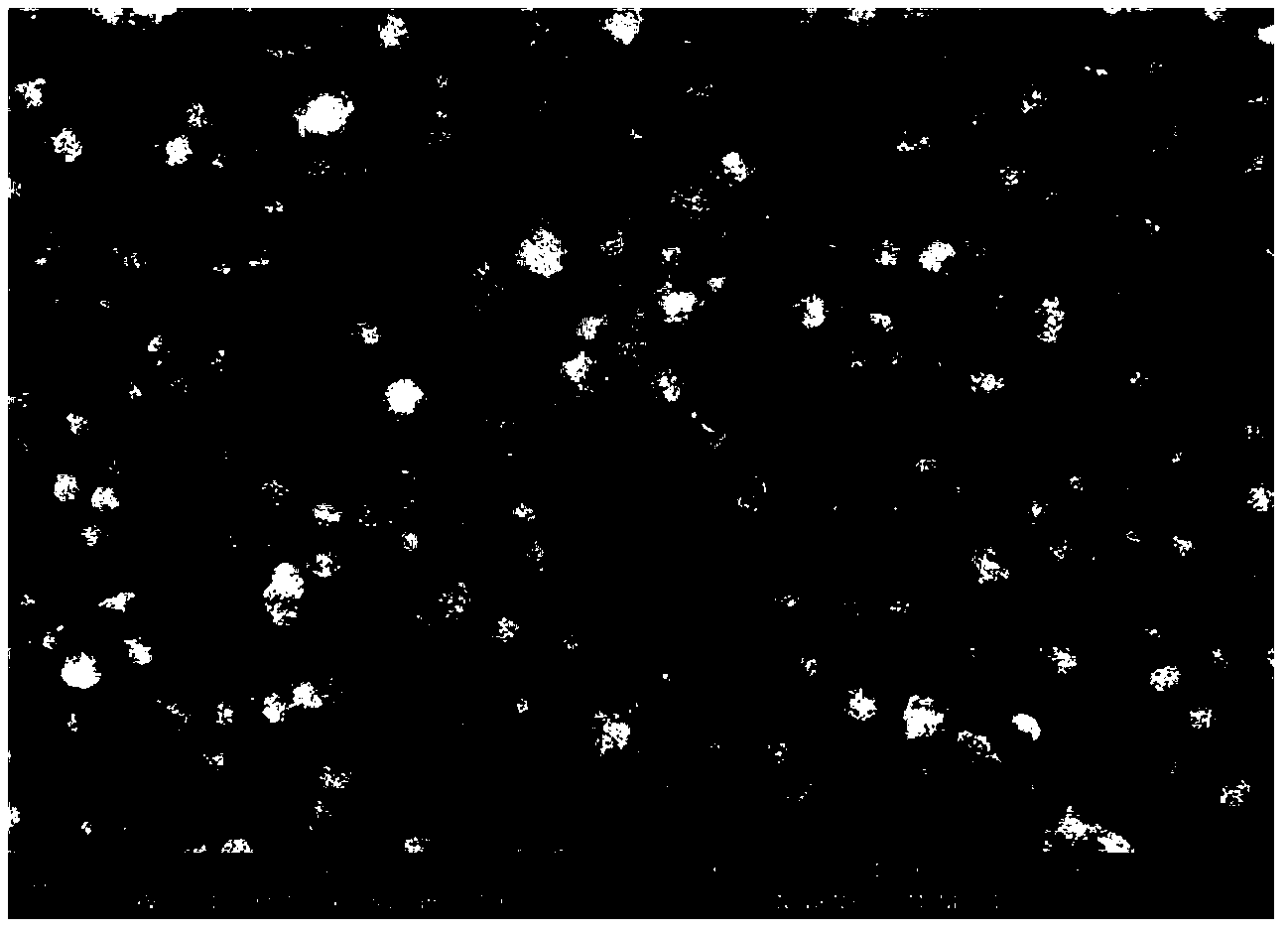

Method used

Image

Examples

Embodiment 1

[0033] This embodiment relates to a barium titanate / polymer composite material with a high dielectric constant, and the composite material includes the following components in volume percentage:

[0034] Barium titanate ceramic particles 60%,

[0035] Hyperbranched Polyamide 20%,

[0036] Polymethylmethacrylate 20%,

[0037] Wherein, the relative dielectric constant of hyperbranched polyamide is 4-10, and the relative dielectric constant of polymethyl methacrylate is 3-4.

[0038] This embodiment also relates to a method for preparing a barium titanate / polymer composite material with a high dielectric constant, comprising the following steps:

[0039] Step 1, disperse 50g of barium titanate ceramic particles into 300ml of 30% hydrogen peroxide solution, heat to 120°C, stir for 1 hour, centrifuge to separate the barium titanate particles, and dry them in vacuum to obtain refined barium titanate ceramic particles;

[0040] Step 2, then disperse the refined barium titanate cer...

Embodiment 2

[0046] This embodiment relates to a barium titanate / polymer composite material with a high dielectric constant, and the composite material includes the following components in volume percentage:

[0047] Barium titanate ceramic particles 53%,

[0048] Linear Polyamide 11%,

[0049] Polymethylmethacrylate 36%,

[0050] Among them, the relative dielectric constant of linear polyamide is 4-10, and the relative dielectric constant of polymethyl methacrylate is 3-4.

[0051] This embodiment also relates to a method for preparing a barium titanate / polymer composite material with a high dielectric constant, comprising the following steps:

[0052] Step 1, disperse 100g of barium titanate ceramic particles into 500ml of 30% hydrogen peroxide solution, heat to 105°C, stir for 4 hours, centrifuge to separate the barium titanate particles, and dry them in vacuum to obtain refined barium titanate ceramic particles;

[0053] Step 2: Disperse refined barium titanate ceramic particles int...

Embodiment 3

[0059] This embodiment relates to a barium titanate / polymer composite material with a high dielectric constant, and the composite material includes the following components in volume percentage:

[0060] Barium titanate ceramic particles 1%,

[0061] Hyperbranched Amide 30%,

[0062] Polymethylmethacrylate 69%,

[0063] Wherein, the relative dielectric constant of hyperbranched polyamide is 4-10, and the relative dielectric constant of polymethyl methacrylate is 3-4.

[0064] This embodiment also relates to a method for preparing a barium titanate / polymer composite material with a high dielectric constant, comprising the following steps:

[0065] Step 1, disperse 50g of barium titanate ceramic particles into 400ml of 30% hydrogen peroxide solution, heat to 60°C, stir for 6 hours, centrifuge to separate the barium titanate particles, and dry them in vacuum to obtain refined barium titanate ceramic particles;

[0066] Step 2: Disperse refined barium titanate ceramic particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com