Method for preparing copper-doped zinc oxide nano-comb

A nano-zinc oxide, copper-doped technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of lack of detailed reports, and achieve the effect of simple equipment, convenient operation and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Embodiment one: the preparation method of copper-doped zinc oxide nano-comb of the present invention, its embodiment is as follows:

[0024] 1) Cut the copper sheet to 1.5cm 1.5cm size.

[0025] 2) Put 1.5cm The 1.5cm pure copper substrate was immersed in dilute hydrochloric acid and ultrasonically cleaned for 10 minutes to remove surface oxides, then ultrasonically cleaned in acetone, deionized water and ethanol solutions for 10 minutes each, and then soaked in ethanol for use.

[0026] 3) Put zinc oxide powder and carbon powder in a mass ratio of 1:1, grind and mix them evenly, put them into a quartz boat, and move them into the heating center area of the tube furnace.

[0027] 4) Dry the ultrasonically cleaned substrate (pure copper substrate) in argon, put it into a specific area of the tube furnace, and then pass argon into the furnace.

[0028] 5) Set the temperature control program to start the tube furnace, raise the temperature of the system to 920°C, ...

specific Embodiment approach 2

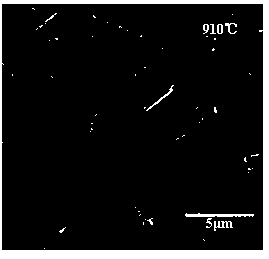

[0030] Embodiment 2: This embodiment is different from Embodiment 1 in that the growth temperature is 910°C.

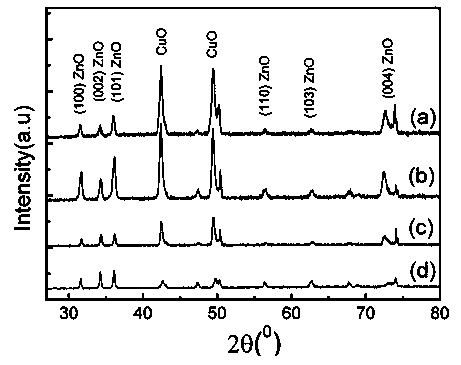

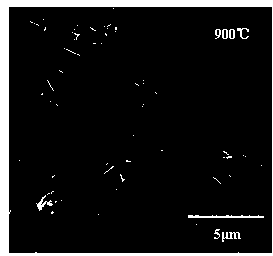

[0031] Thermal diffusion will occur between different atoms in different substances in contact with each other at high temperature due to the concentration gradient. Since the growth of ZnO nanocombs is carried out on the surface of high-temperature copper foil, ZnO and CuO can also be observed through the X-ray diffraction pattern of the sample. Therefore, it can be judged that the precipitate is copper-doped zinc oxide. In addition, through the SEM photo of the precipitate, it can be visually observed that the precipitate is in the shape of a nano-comb, and the size is on the nanometer scale. Depend on Figure 1-5 It can be seen that when the growth temperature is 910 and 920 °C, the morphology of the sample is nano-comb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com