Pesticide and its preparation for controlling fungal and bacterial diseases of crops

A bacterial and pesticide technology, applied in the field of pesticides, can solve the problems of poor long-term use effect, drug resistance of diseases, single ingredients, etc., and achieve the effect of overcoming and bacterial drug resistance, no three wastes, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

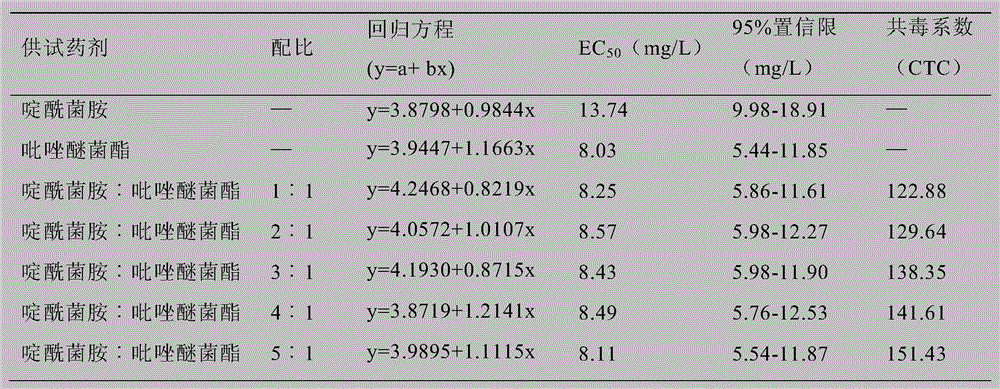

Method used

Image

Examples

Embodiment 1

[0023] Proportion and production process of 30% boscalid water-dispersible granules

[0024] The following ingredients are included in terms of weight percentage: boscalid 30%, dispersant (sodium methylene bis-naphthalene sulfonate) 3%, wetting agent (sodium dodecyl sulfonate) 2%, disintegrant (ammonium sulfate ) 1%, binder (xanthan gum) 1%, filler (kaolin) to make up.

[0025] Boscalid original drug, dispersant, wetting agent, disintegrating agent, filler, etc. are mixed together, jet milled to obtain a particle size of about 500 mesh, and then a binder is added for mixing to obtain a granulation material. Quantitatively send the material into the fluidized bed granulation dryer for granulation and drying to obtain 30% boscalid water-dispersible granules. After the analysis is qualified, the whole production process will be completed by packaging.

Embodiment 2

[0027] The formula and process of 40% boscalid suspension concentrate are as follows

[0028] The following ingredients are included in terms of weight percentage: 40% boscalid, 12% dispersant (sodium methylene bis-naphthalene sulfonate), 10% wetting agent (sodium dodecyl sulfonate), defoamer (organic silicon ) 0.5%, thickener (xanthan gum) 0.01%, antifreeze (ethylene glycol) 0.01%, deionized water balance.

[0029] Mix the dispersant, wetting agent, defoamer, thickener, and antifreeze in the above formula evenly through high-speed shearing, add the original drug of boscalid, and mill in a ball mill for 2 to 3 hours to make the particle size completely Below 5 μm, the product of boscalid suspension concentrate is prepared, and the whole production process is completed after the analysis is qualified and repacked.

Embodiment 3

[0031] Proportion and production process of 40% boscalid wettable powder

[0032] It includes the following components in terms of weight percentage: 40% boscalid, 5% dispersant (sodium methylene bis-naphthalene sulfonate), 4% wetting agent (sodium dodecyl sulfonate), and supplementary filler (kaolin).

[0033] Mix the original drug of boscalid with dispersant, wetting agent, disintegrating agent, filler, etc., and jet mill to obtain a particle size of about 500 mesh, and then perform secondary mixing to obtain 40% boscalid wettability Powder products. After the analysis is qualified, the whole production process will be completed by packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com