Preparation method for small-size high-dispersion fuel battery catalyst

A fuel cell and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of complex process flow, low dispersion and harsh conditions for the preparation of Pt nanoparticle catalysts, and achieve production costs. Inexpensive, highly dispersed, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

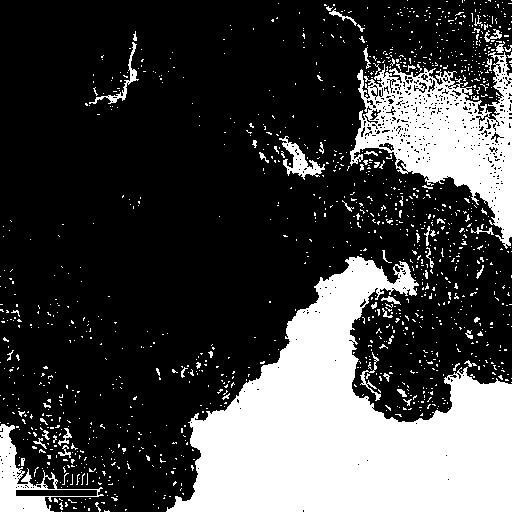

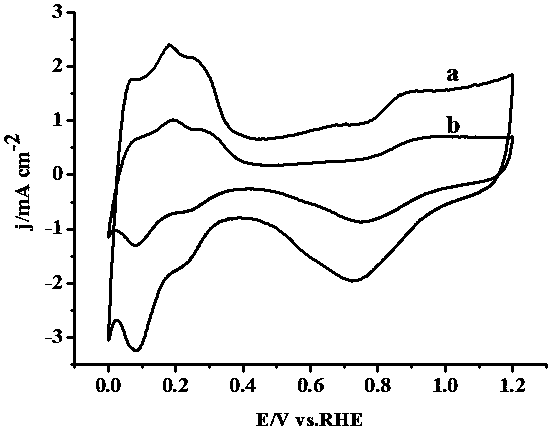

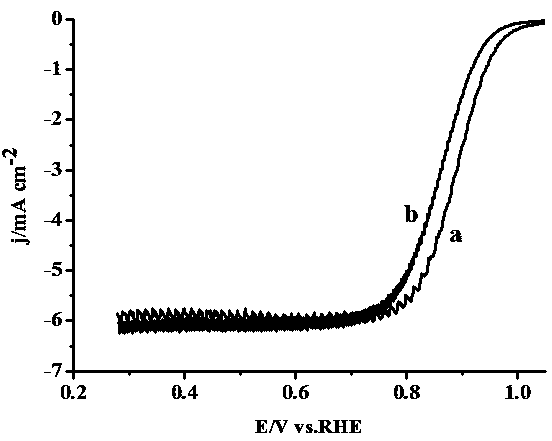

Image

Examples

Embodiment 1

[0027] (1) Functional treatment of carbon support

[0028]Weigh 1 gram of commercially available Vulcan XC-72 carbon powder, add 150 ml of a mixed solution of hydrogen peroxide and concentrated sulfuric acid with a volume ratio of 1:4, wherein the mass percent concentration of hydrogen peroxide is 30%, and stir with ultrasonic oscillation After 3 hours, dilute it with ultrapure water, let it stand for 24 hours, filter out the supernatant, and get the functionalized Vulcan XC-72 carbon powder after several times of centrifugal washing, drying, and grinding.

[0029] (2) Preparation of NiFe / C nanoparticles

[0030] Weigh nickel acetylacetonate, Iron acetylacetonate, oleic acid, sodium hydroxide, sodium borohydride and functionalized Vulcan XC-72 carbon powder, nickel acetylacetonate, iron acetylacetonate, oleic acid, sodium hydroxide and 75mL ethylene glycol were added to a 250mL three-necked flask , raise the temperature to 130°C while stirring under a nitrogen atmosphere, ke...

Embodiment 2

[0035] Step (1) is the same as step (1) in Example 1.

[0036] (2) Preparation of NiFe / C nanoparticles

[0037] Weigh nickel acetylacetonate, Iron acetylacetonate, oleic acid, sodium hydroxide, sodium borohydride and functionalized Vulcan XC-72 carbon powder, nickel acetylacetonate, iron acetylacetonate, oleic acid, sodium hydroxide and 50mL ethylene glycol were added to a 250mL three-necked flask , raise the temperature to 110°C while stirring under a nitrogen atmosphere, keep it for 1.5 hours, and then continue to heat up to 150°C, slowly add sodium borohydride to the above mixed solution, the addition time is controlled at 10 minutes, after the addition is completed, at 150°C Continue to react for 20 minutes, then cool the reaction solution to 70°C, add functionalized Vulcan XC-72 carbon powder, stir and adsorb for 12 hours, wash the product with absolute ethanol for 3 times, vacuum dry at 70°C for 6 hours, and grind it NiFe / C nanoparticles were obtained.

[0038] (3) Pr...

Embodiment 3

[0043] Step (1) is the same as step (1) in Example 1.

[0044] (2) Preparation of NiFe / C nanoparticles

[0045] According to the mass ratio of nickel acetylacetonate: iron acetylacetonate: oleic acid: sodium hydroxide: sodium borohydride: functionalized Vulcan XC-72 carbon powder is 1: 1.375: 0.022: 0.016: 7.363: 1.557 respectively take nickel acetylacetonate, Iron acetylacetonate, oleic acid, sodium hydroxide, sodium borohydride and functionalized Vulcan XC-72 carbon powder, nickel acetylacetonate, iron acetylacetonate, oleic acid, sodium hydroxide and 100mL ethylene glycol were added to a 250mL three-necked flask , raise the temperature to 120°C while stirring under a nitrogen atmosphere, keep it for 2 hours, and then continue to heat up to 140°C, slowly add sodium borohydride to the above mixed solution, the addition time is controlled at 15 minutes, after the addition is completed, at 140°C Continue to react for 30 minutes, then cool the reaction solution to 80°C, add fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com