Environment-friendly anti-bacterial PVC (Polyvinyl Chloride) thin film

A technology of PVC film and PVC resin powder, applied in the field of polymer materials, can solve the problems of harmful plasticizers, little research on the application of PVC film, human health hazards, etc., to avoid health problems, excellent bacteriostatic and antiseptic effect, The effect of significantly inhibiting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

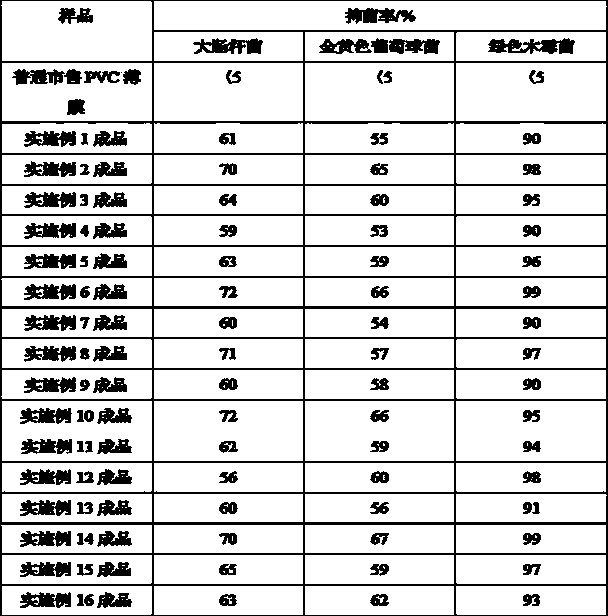

Examples

Embodiment 1

[0028] Environmentally friendly antibacterial PVC film, including the following raw materials in parts by mass: 90 parts of PVC resin powder, 0.1 part of lavender essential oil, 20 parts of acetyl tri-n-butyl citrate, 4 parts of calcium ricinoleate, 0.2 parts of glyceryl stearate share.

[0029] The preparation method of the lavender essential oil is as follows: weigh 20g of lavender flowers, pass through a 60-mesh sieve after crushing, place in a 250mL beaker, add 150mL of n-hexane, soak for 30min, place in an ultrasonic instrument, ultrasonicate for 60min at 40°C, and cool to room temperature , Distilled under reduced pressure, the concentrated solution is lavender essential oil.

[0030] The preparation method of the present invention: add 90 parts of PVC resin powder, 0.1 part of lavender essential oil, 20 parts of acetyl tri-n-butyl citrate, 4 parts of calcium ricinoleate and 0.2 part of glyceryl stearate into a high-speed mixer according to the parts by mass Raise the t...

Embodiment 2

[0034] The environment-friendly antibacterial PVC film comprises the following raw materials in parts by mass: 110 parts of PVC resin powder, 0.2 part of lavender essential oil, 25 parts of acetyl tri-n-butyl citrate, 8 parts of magnesium stearate, and 0.6 part of paraffin.

[0035] The preparation method of the lavender essential oil is as follows: weigh 20g of lavender flowers, pass through a 60-mesh sieve after crushing, place in a 250mL beaker, add 200mL of n-hexane, soak for 50min, place in an ultrasonic instrument, ultrasonicate for 80min at 50°C, and cool to room temperature , Distilled under reduced pressure, the concentrated solution is lavender essential oil.

[0036] The preparation method of the present invention: add 110 parts of PVC resin powder, 0.2 part of lavender essential oil, 25 parts of acetyl tri-n-butyl citrate, 8 parts of magnesium stearate and 0.6 part of paraffin into a high-speed mixer and heat up to 90 °C according to the parts by mass Stir and mix ...

Embodiment 3

[0040] Environmentally friendly antibacterial PVC film, including the following raw materials in parts by mass: 95 parts of PVC resin powder, 0.12 parts of lavender essential oil, 23 parts of acetyl tri-n-butyl citrate, 4 parts of calcium ricinoleate, and 2 parts of magnesium stearate 0.2 parts of glyceryl stearate.

[0041] The preparation method of the lavender essential oil is as follows: weigh 20g of lavender flowers, pass through a 60-mesh sieve after crushing, place in a 250mL beaker, add 180mL of n-hexane, soak for 45min, place in an ultrasonic instrument, ultrasonicate for 75min at 45°C, and cool to room temperature , Distilled under reduced pressure, the concentrated solution is lavender essential oil.

[0042] The preparation method of the present invention: mix 95 parts of PVC resin powder, 0.12 part of lavender essential oil, 23 parts of acetyl tri-n-butyl citrate, 4 parts of calcium ricinoleate, 2 parts of magnesium stearate and 0.12 part of lavender essential oil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com