Wave-absorbing material and preparation method thereof

A technology of wave absorbing material and carbonyl iron powder, applied in the field of wave absorbing material, can solve the problems of limiting the practical application range of carbonyl iron powder, large eddy current effect, increasing the density of wave absorbing material, etc., and achieving electromagnetic parameters and wave absorbing performance. , suppress the skin effect, improve the effect of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] (1) A preparation method of a wave-absorbing material

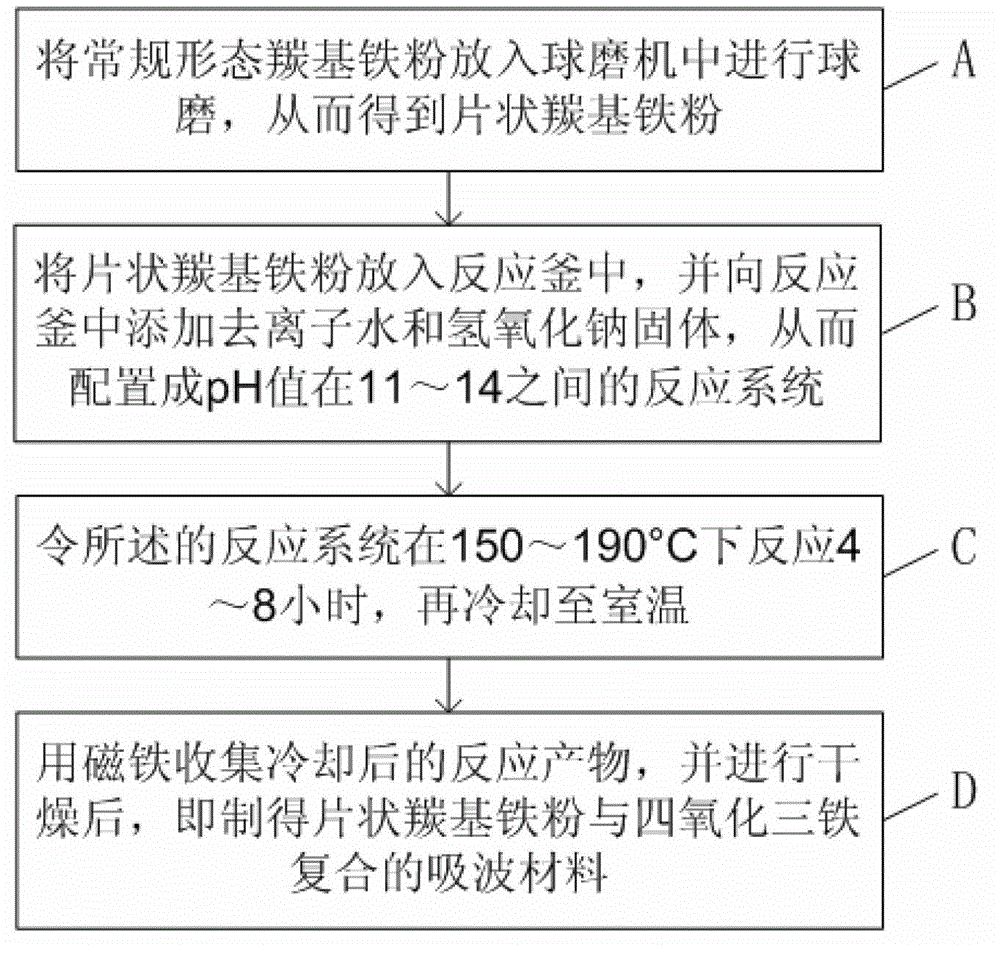

[0035] Such as figure 2 Shown, a kind of preparation method of absorbing material can specifically comprise the following steps:

[0036] Step A: put the carbonyl iron powder in a conventional form into a ball mill for ball milling, so as to obtain flake carbonyl iron powder.

[0037] Specifically, this step A may include the following steps:

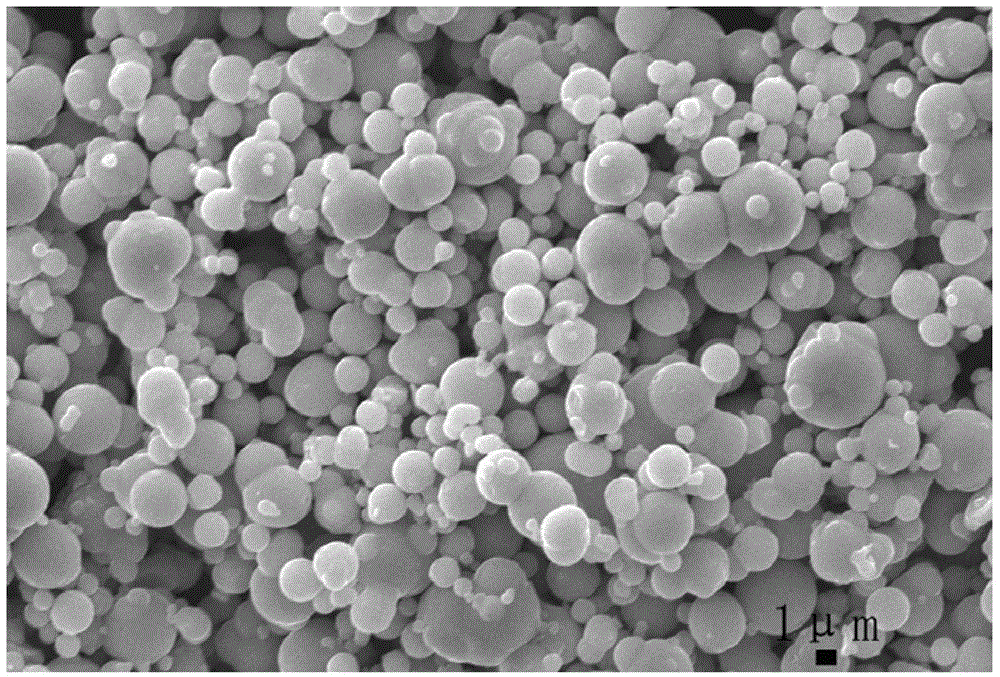

[0038] Step A1. Prepare a mixture of conventional carbonyl iron powder and absolute ethanol at a weight ratio of 1:2 to 1:3; among them, conventional carbonyl iron powder with a particle size of 0.5 to 8 μm is best selected. Iron powder, its microscopic appearance can be as follows figure 1 shown.

[0039] Step A2, put the prepared mixture into a ball mill, the weight ratio of the ball to material is 5:1-10:1, the speed of the ball mill is 400-500rpm, and the flake carbonyl iron powder is obtained after ball milling for 4-8 hours; , the balls in the ball mill are prefe...

Embodiment 1

[0052] A method for preparing a wave-absorbing material may specifically include the following steps:

[0053] Step 1, mix 30g such as figure 1 The carbonyl iron powder in the conventional form shown (the particle size of the carbonyl iron powder in the conventional form is between 0.5 and 8 μm) is mixed with 90ml of absolute ethanol, and put into the spherical tank of the planetary ball mill; Put corundum balls of different diameters, the weight ratio of balls to materials is 10:1, and mill at a speed of 450rpm for 6 hours to obtain flaky carbonyl iron powder with a thickness of about 100nm.

[0054] Step 2, take 20g of the flaky carbonyl iron powder obtained in the above step 1, and put 170ml of deionized water into the reactor, then add solid sodium hydroxide to the reactor until the pH value in the reactor is equal to 12, thereby A reaction system with a pH equal to 12 was formed.

[0055] Step 3. Allow the reaction system formed in step 2 to react at 170° C. for 6 hours...

Embodiment 2

[0058] A preparation method of a wave-absorbing material, the difference from Example 1 is that what is formed in step 2 is a reaction system with a pH value equal to 13 (the reaction system can be controlled by adjusting the amount of sodium hydroxide solid added). pH value); finally, composite wave-absorbing materials of flaky carbonyl iron powder and ferroferric oxide can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com