Preparation method of silsesquioxane complex catalyst with excellent activity

A technology of silsesquioxane and catalyst, which is applied in the field of electrochemical power supply to achieve the effect of preventing aggregation, improving activity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of POSS-Co complex catalyst

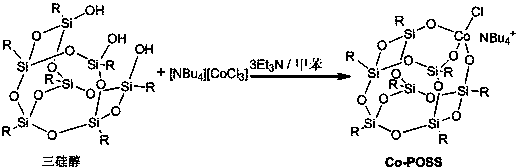

[0036] The synthetic route of POSS-Co complex is as follows figure 1 shown. Divided into the following steps:

[0037] (1). Preparation of isobutyl-POSS trisilanol: Add 4.36g (5mmol) of isobutyl octasilsesquioxane to a 500mL flask, dissolve it in 250mL of chloroform, and place it in an oil bath at 55°C Heating on top, slowly adding 0.8-1.6mL of concentrated sulfuric acid dropwise, stirring for 18h and recrystallizing with tetrahydrofuran to obtain about 3.21g of isobutyl-POSS trisilanol with a yield of 75-81%.

[0038] (2). The preparation of tetrabutylamine cobalt trichloride salt, 2g CoCl 2 .6H 2 O (8.4mmol) was dissolved in 100mL of 9M hydrochloric acid, and 16.8mL of 1mol / L tetrabutylammonium chloride solution (4.66g, 16.8mmol) was added dropwise under vigorous stirring, and a pink precipitate was obtained immediately. After washing, vacuum-dry to obtain quaternized cobaltous chloride (2.8g, 6.8mmol, yie...

Embodiment 2

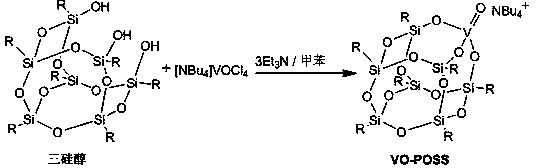

[0046] Embodiment 2: the preparation of POSS-VO complex catalyst

[0047] (1). Preparation of isobutyl-POSS trisilanol: same as Example 1.

[0048] (2). The preparation of tetrabutylamine vanadyl chloride tetrachloride, the [Bu of 1.024g 4 ]VO 3 (3mmol) was dissolved in 20mL of 9M hydrochloric acid, stirred overnight under the condition of vigorous stirring, then added DMSO and cooled to -10°C to obtain yellow crystals, which were tetrabutylamine vanadyl tetrachloride, and the product quality was 1.03g , yield 83%, use benzene as solvent to dissolve and obtain the solution B liquid of metal salt;

[0049] (3). Dissolve the isobutyl-POSS trisilanol (2.5mmol, 1.98g) prepared in the above step (1) in 30-35mL of toluene to liquid A, and then add 0.35-0.7mL to liquid A (2.5 ~ 5mmol) of triethylamine as a catalyst, after stirring at room temperature for 10min, slowly add 2.5 ~ 5mL of 1mol / L liquid B to mix, and stir overnight in an oil bath at 40°C, using the hydroxyl group as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com