Workpiece curved surface position welding repairing method

A repair method and workpiece technology, applied in the field of welding repair, can solve the problems of unfavorable large-scale production, aggravated negative effects of surface wear, slow repair speed, etc., achieve good high temperature non-wettability, good welding repair effect, and save energy The effect of solder use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 : A method for repairing the inner curved surface of a golf head by welding, which specifically includes the following steps:

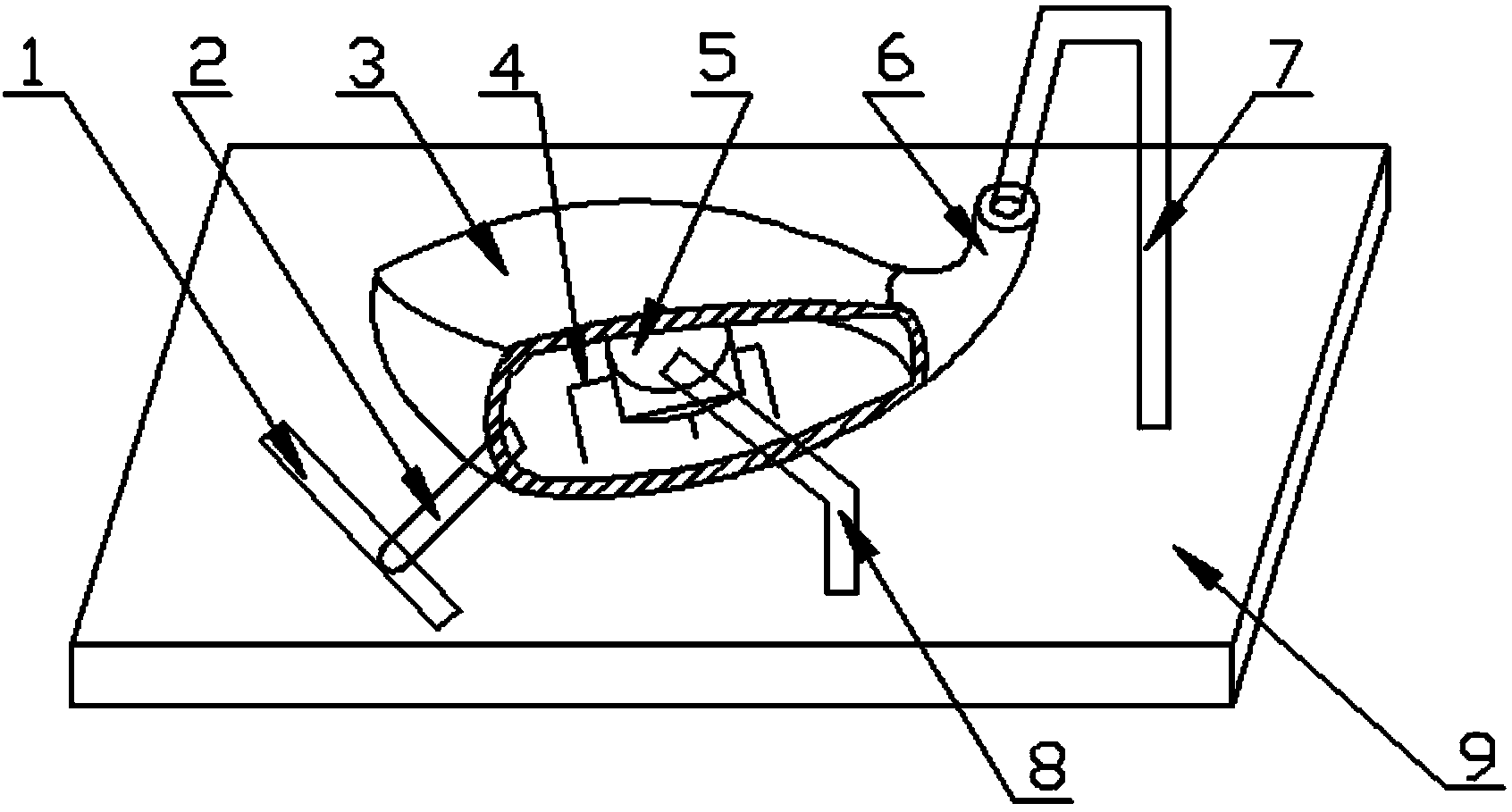

[0027] (1) The golf TC4 (alloy composition Ti-6Al-4V) titanium alloy cavity golf head prepared by precision casting with a negative deviation relative to the standard weight is the welding repair object, and the ball head usually has a negative deviation 1~5g, the welding repair position is required to be located on the inner surface of the cavity, and the surface is uniform and the shape is consistent with the design cavity surface, see figure 1 ;

[0028] (2) Measure the actual weight of the golf head, and determine the weight to be repaired by welding based on the difference between the standard weight and the actual weight;

[0029] (3) Select the uneven thinner part by measuring the golf head as the part to be repaired by welding;

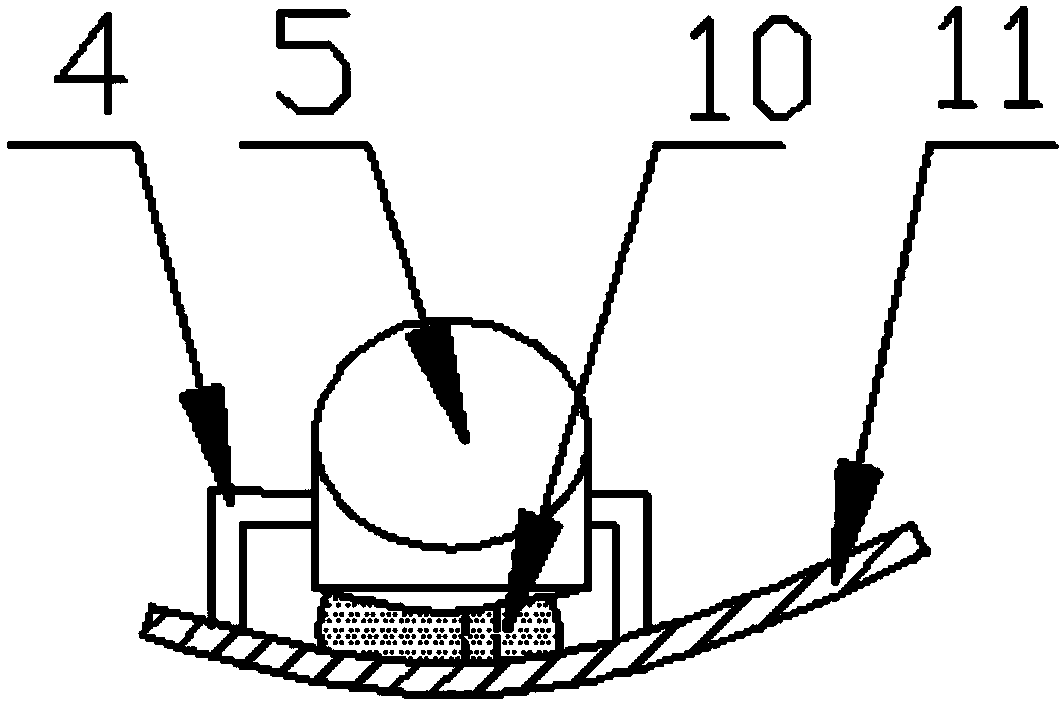

[0030] (4) Alumina with a purity of 99.9% and a grain size of 1μm (Al 2 O 3 ) Produce a ceramic mold with...

Embodiment 2

[0038] Example 2 : A method for repairing the surface of a superalloy blade by welding, which specifically includes the following steps:

[0039] (1) The material of the workpiece to be repaired by welding is GH586 high-temperature alloy (solid solution state 760℃ / 16h+1080℃ / 4h) in the heat-treated state after rolling, and its chemical composition is C: 0.05, Cr: 19.3, Co: 11.2, W: 2.95, Mo: 8.17, Ti: 3.28 (wt%), the shape of the workpiece to be repaired by welding is a turbine blade with corrosion pit damage on the surface;

[0040] (2) Determine the defect range of the blade to be welded and repaired, and determine the amount of welding powder solder according to the actual defect range and degree;

[0041] (3) The solder is nickel-based amorphous powder solder, the composition is Ni 82 Cr 7.5 Fe 3 Si 4.5 B 3 (Impurity C <0.06%) (wt%);

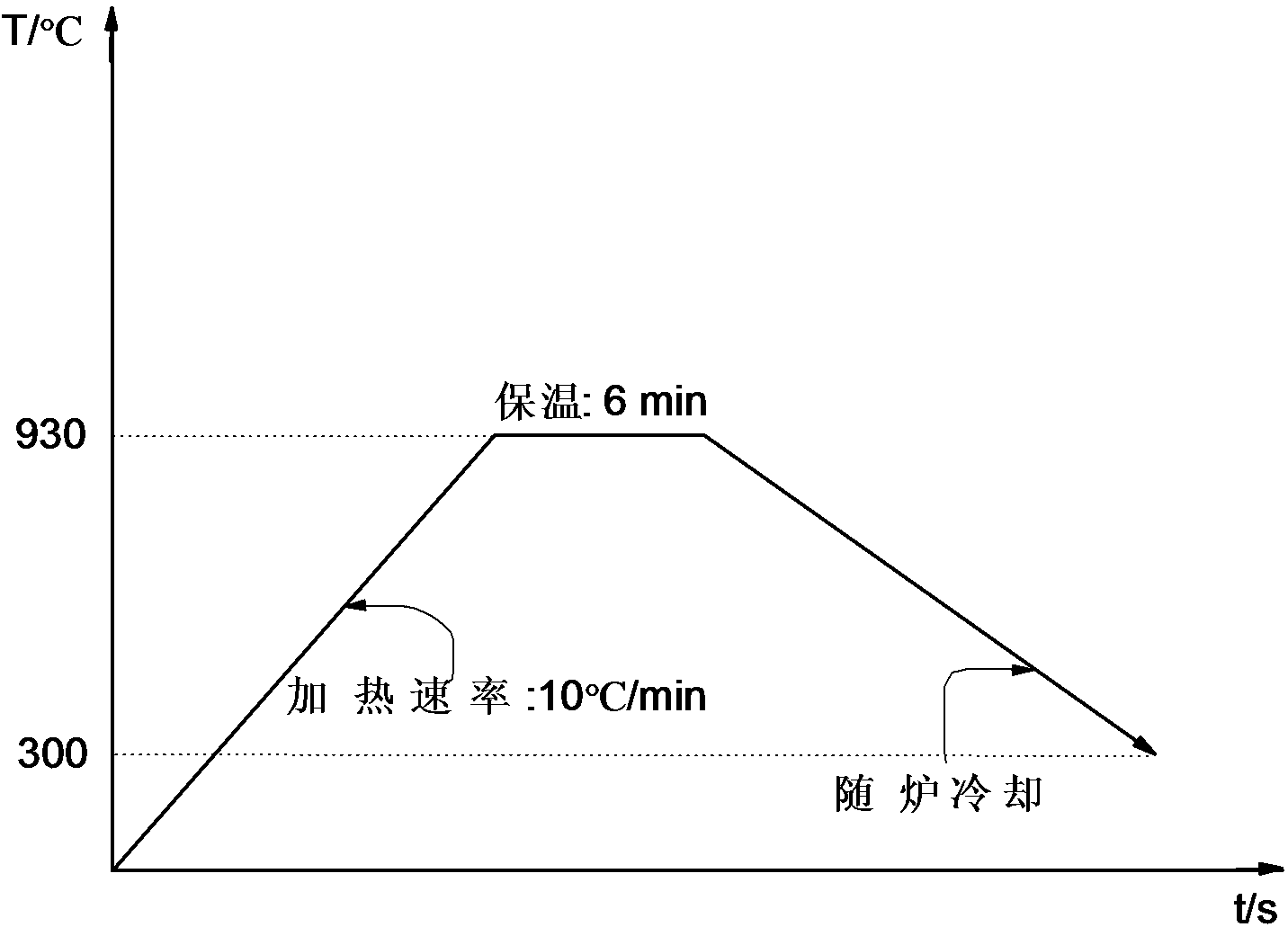

[0042] (4) Use a micro-grinding electric drill to polish the pit-corrosion defect to remove the oxide and rust layer of the part, then polish it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com