Epoxy modified nitrocellulose enamel and preparation method thereof

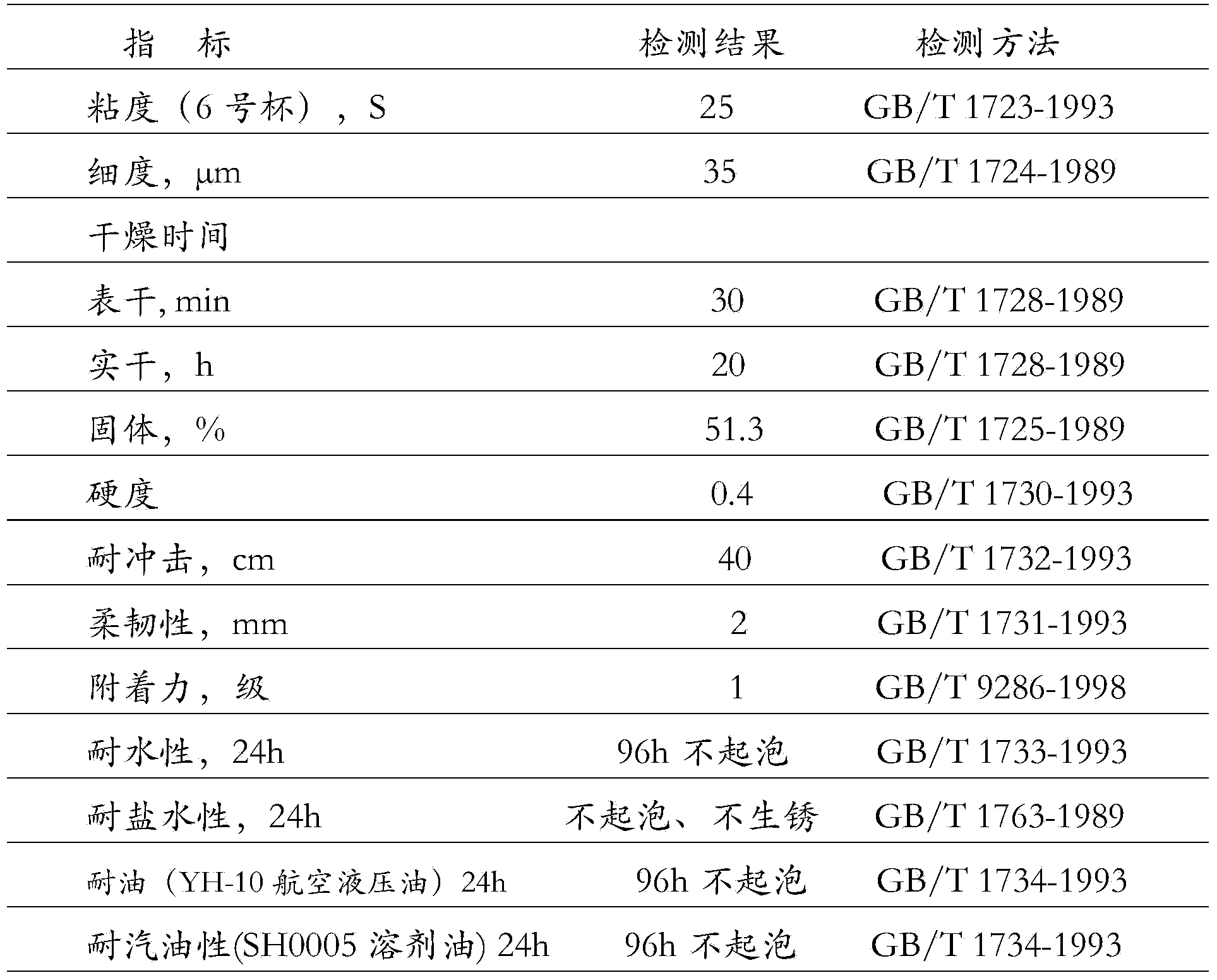

A technology of nitro enamel and epoxy modification, applied in epoxy resin coatings, coatings, anti-corrosion coatings and other directions, can solve the problems of poor flexibility, low gloss, poor adhesion, etc., and achieves a simple preparation method, Excellent adhesion and good oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An alkyd resin solution (64.1% by weight solids), consisting of tung oil, linseed oil, glycerin, lithium hydroxide, phthalic anhydride, refluxing xylene and xylene, wherein tung oil 18kg, linseed oil 21kg, glycerin 11kg, lithium hydroxide 0.02kg , phthalic anhydride 17kg, reflux xylene 4.5kg, xylene 33kg, concrete preparation steps are as follows:

[0042] (1) Add tung oil, linseed oil and glycerin to the reaction kettle and stir to raise the temperature;

[0043] (2) Pass CO 2 gas, heating up to 100°C and adding lithium hydroxide;

[0044] (3) Heat up to 220°C to maintain alcoholysis, and dissolve the sample in absolute ethanol until transparent;

[0045] (4) After passing the alcoholysis, cool down to 180°C and add phthalic anhydride and reflux xylene;

[0046] (5) After adding phthalic anhydride, raise the temperature to 210°C to maintain the reaction. When the acid value reaches 52mgKOH / g and the viscosity reaches 1.8 seconds, remove from the fire and cool down; ...

Embodiment 2

[0049] An alkyd resin liquid (66.7% by weight solids), consisting of tung oil, flax oil, glycerin, lithium hydroxide, phthalic anhydride, refluxing xylene and xylene, wherein 25kg of tung oil, 15kg of linseed oil, 5kg of glycerin, and 0.03kg of lithium hydroxide , phthalic anhydride 25kg, reflux xylene 5kg, xylene 30kg, the concrete preparation steps are as follows:

[0050] (1) Add tung oil, linseed oil and glycerin to the reaction kettle and stir to raise the temperature;

[0051] (2) Pass CO 2 gas, heating up to 100°C and adding lithium hydroxide;

[0052] (3) Heat up to 220°C to maintain alcoholysis, and dissolve the sample in absolute ethanol until transparent;

[0053] (4) After passing the alcoholysis, cool down to 180°C and add phthalic anhydride and reflux xylene;

[0054] (5) After adding phthalic anhydride, raise the temperature to 210°C to maintain the reaction. When the acid value reaches 55mgKOH / g and the viscosity reaches 1.5 seconds, remove from the fire and c...

Embodiment 3

[0057] An alkyd resin solution (66.7% by weight solids), consisting of tung oil, linseed oil, glycerin, lithium hydroxide, phthalic anhydride, refluxing xylene and xylene, wherein tung oil 15kg, linseed oil 25kg, glycerin 15kg, lithium hydroxide 0.01kg , phthalic anhydride 15kg, reflux xylene 3kg, xylene 32kg, the concrete preparation steps are as follows:

[0058] (1) Add tung oil, linseed oil and glycerin to the reaction kettle and stir to raise the temperature;

[0059] (2) Pass CO 2 gas, heating up to 100°C and adding lithium hydroxide;

[0060] (3) Heat up to 220°C to maintain alcoholysis, and dissolve the sample in absolute ethanol until transparent;

[0061] (4) After passing the alcoholysis, cool down to 180°C and add phthalic anhydride and reflux xylene;

[0062] (5) After adding phthalic anhydride, raise the temperature to 210°C to maintain the reaction. When the acid value reaches 45mgKOH / g and the viscosity reaches 2.0 seconds, remove from the heat and cool down...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com