Biomass boiler anticorrosive agent, and preparation and application thereof

A technology for biomass boilers and anti-corrosion agents, which is used in fuel additives, petroleum industry, solid fuels, etc., can solve the problems of reduced corrosion resistance of pipes, accelerated corrosion, loss of metals, etc., to reduce alkali metal corrosion and chlorine corrosion, structural Stable, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

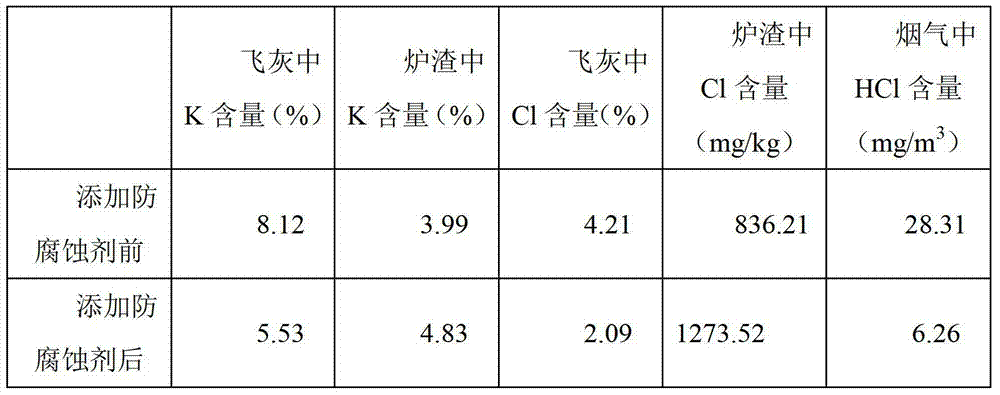

Embodiment 1

[0019] A kind of anticorrosion agent for biomass boiler, which is composed of coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 Composition, the mass of each component in the anti-corrosion agent is: 4kg coal ash (particle size 0.05-0.015mm), 2kg Al 2 (SO4) 3 , 3kg kaolin, 1kg CaSO 4 .

[0020] Above-mentioned biomass boiler corrosion inhibitor, its preparation method is as follows:

[0021] Step (1): Calcining 4kg of coal ash with a particle size of 0.05-0.15mm in a muffle furnace at 1000°C for 1 hour;

[0022] Step (2): Add 2kgAl 2 (SO4) 3 , 3kg kaolin, and 1kg CaSO 4 Grind to 0.05-0.1mm respectively, and add calcined coal ash for stirring, and after stirring evenly, press to form particles with rough threads on the outer surface.

[0023] Step (3): Bake the anticorrosion agent particles in a muffle furnace at 200°C for 0.5h to prepare the anticorrosion agent for biomass boilers. (of which coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 The mass percentage content is respec...

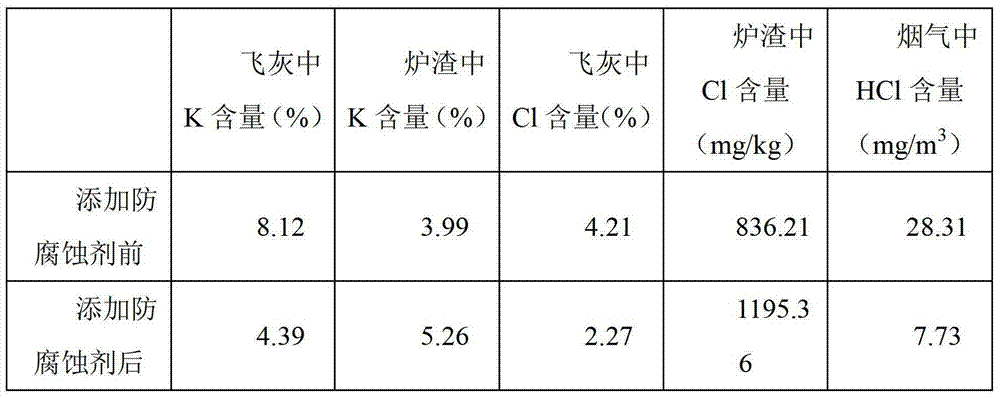

Embodiment 2

[0027] A kind of biomass boiler anticorrosion agent, this anticorrosion agent is made of coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 Composition, the mass of each component in the anti-corrosion agent is: 3kg coal ash (particle size 0.05-0.015mm), 1.5kgAl 2 (SO4) 3 , 4kg kaolin, 1.5kg CaSO 4 .

[0028] Above-mentioned biomass boiler corrosion inhibitor, its preparation method is as follows:

[0029] Step (1): Calcining 3kg of coal ash with a particle size of 0.05-0.15mm in a muffle furnace at 1050°C for 1.5h;

[0030] Step (2): Add 1.5kgAl 2 (SO4) 3 , 4kg kaolin, and 1.5kg CaSO 4 Grind to 0.05-0.1mm respectively, and add calcined coal ash for stirring, and after stirring evenly, press to form particles with rough threads on the outer surface.

[0031] Step (3): Bake the anticorrosion agent particles in a muffle furnace at 150° C. for 1 hour to prepare the anticorrosion agent for biomass boilers. (of which coal ash, Al 2 (SO4) 3 , kaolin and CaSO 4 The mass percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com