Preparation method of nano coating with reduced marine organism attachment on surface of titanium alloy

A nano-coating, titanium alloy technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problem of not having the ability to prevent the adhesion of marine organisms, accelerate the corrosion and damage of base materials, and reduce the safety and reliability of ships. , to achieve the effect of less pollution, extended service life and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

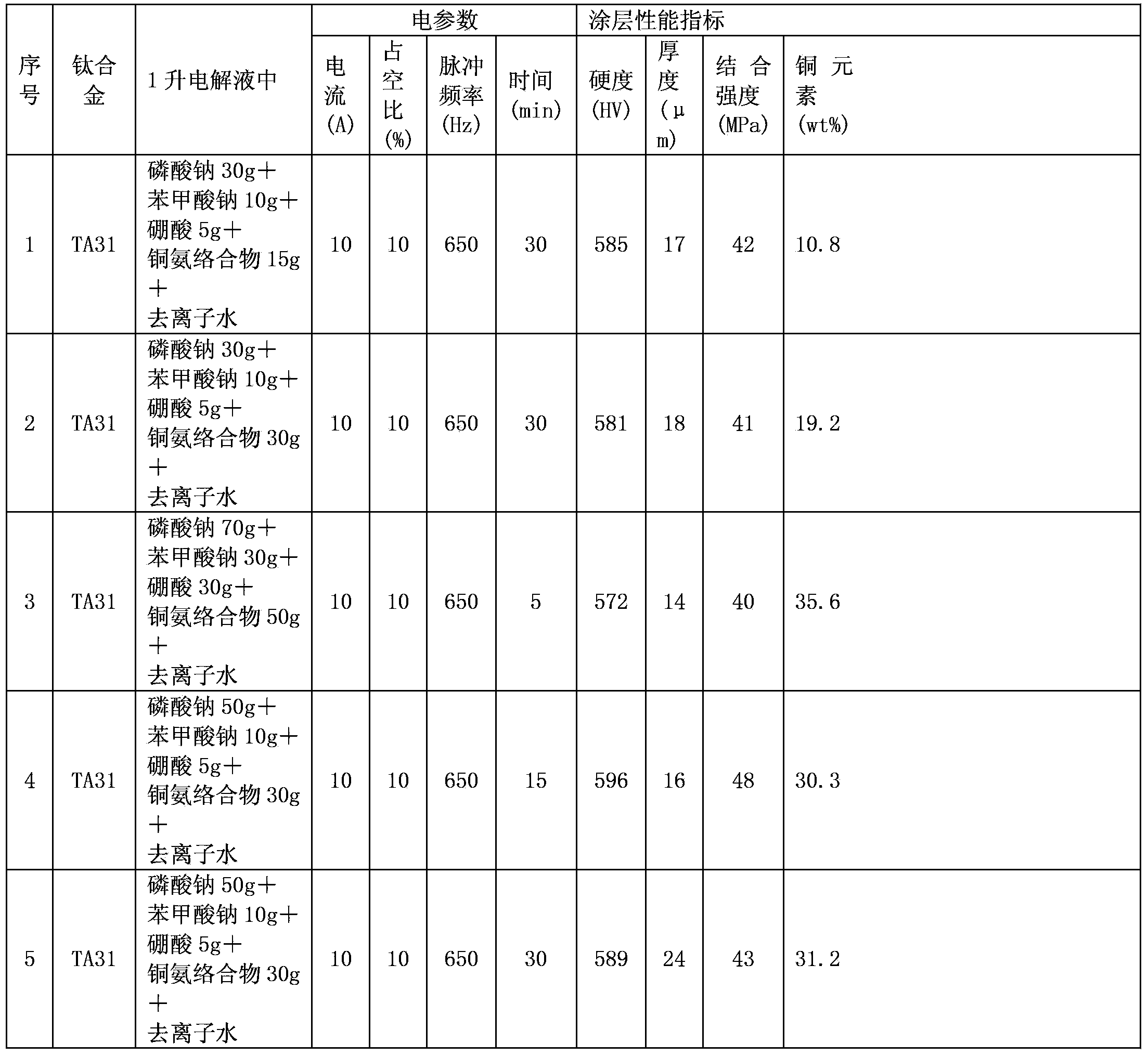

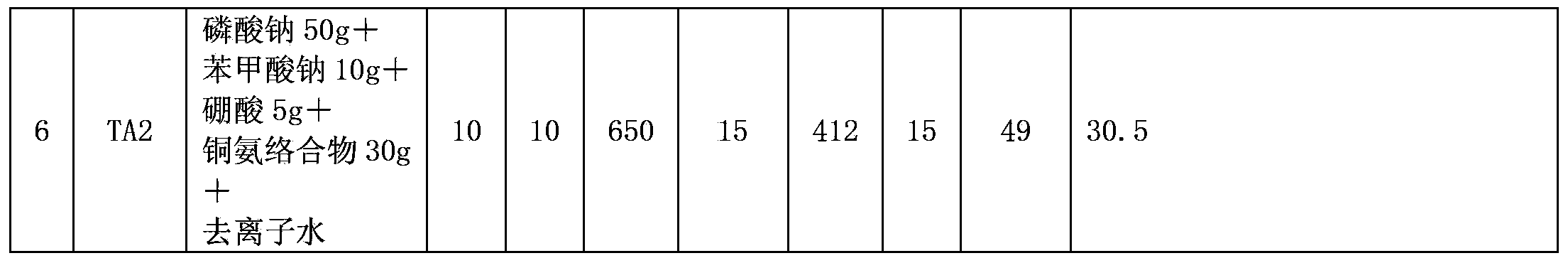

[0019] The invention relates to a method for preparing a nano-coating on the surface of a titanium alloy to reduce the adhesion of marine organisms. A copper-ammonia complex is added to the electrolytic solution, and the copper-ammonia complex is reacted by sodium phosphate, sodium benzoate and boric acid under the action of a device. Low-toxic cuprous oxide Cu was formed under constant electrolysis conditions 2 O and titanium dioxide TiO with nanocrystalline and amorphous structures 2 Ceramic insulating coating, which can greatly reduce the adhesion ability and area of barnacles, mussels, and oysters, and prolong the service life of titanium alloys in seawater.

[0020] The preparation method of the nano-coating of the present invention comprises the pretreatment to the surface of the titanium alloy, the preparation of the nano-coating of the titanium alloy in the electrolyte and the post-treatment of the nano-coating, wherein the pre-treatment is degreasing, degreasing, D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com