Allopurinol sustained-release pellet and preparation method and preparation thereof

A technology of sustained-release pellets and sustained-release preparations, applied in the field of medicine, can solve the problems of increasing the difficulty of preparation, complicated preparation process, and reducing the relative content of allopurinol, so as to achieve the effects of reducing types and dosage and simplifying formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

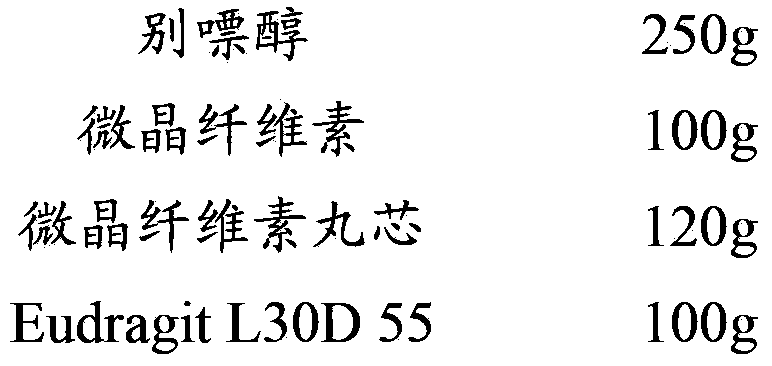

[0059] The preparation of embodiment 1 allopurinol sustained-release pellets

[0060] Weigh each component:

[0061]

[0062] Pass allopurinol through a 80-mesh sieve, mix evenly with microcrystalline cellulose, and put it into the hopper of a centrifugal granulator. Put the microcrystalline cellulose ball core into the centrifugal granulator, turn on the fan, turn on the main engine at a speed of 200rpm, put the silicone tube of the peristaltic pump into the Eudragit L30D55 water dispersion, the peristaltic pump speed at 15rpm, and the feeding speed at 5rpm, Dosing by powder layering. While spraying the water dispersion while feeding, adjust the feeding speed and the speed of the peristaltic pump so that the water dispersion is just used up when the mixed material is used up. After feeding, the main machine continued to run for 5 minutes and then stopped to prepare allopurinol sustained-release pellets, which were dried in an oven at 40°C for 2 hours to obtain the prod...

Embodiment 2

[0063] The preparation of embodiment 2 allopurinol sustained-release pellets

[0064] Weigh each component:

[0065]

[0066] Pass allopurinol through an 80-mesh sieve, mix with starch evenly, and set aside. Sodium alginate is dissolved in purified water to form a gel-like solution, which is used as a binder to make a soft material for the mixture. Put the soft material into the feed hopper of the extrusion-spheronizer, the screen aperture is 1mm, the extrusion frequency is 20Hz, and the spheronization frequency is 30Hz, and the prepared allopurinol sustained-release pellets are dried in an oven at 40°C for 2 hours to obtain .

Embodiment 3

[0067] The preparation of embodiment 3 allopurinol sustained-release pellets

[0068] Weigh each component:

[0069] Allopurinol 250g

[0070] Eudragit S100 20g

[0071] Ethanol 200g

[0072] Pass allopurinol through an 80-mesh sieve and set aside. Dissolve Eudragit S100 in ethanol to form a solution with high viscosity, which is used as an adhesive for soft materials made of allopurinol. Put the soft material into the feed hopper of the extrusion-spheronizer, the screen aperture is 1mm, the extrusion frequency is 20Hz, and the spheronization frequency is 30Hz, and the prepared allopurinol sustained-release pellets are dried in an oven at 40°C for 2 hours to obtain .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com