Absorbable endocranium healing patch and preparation method thereof

A dura mater and patch technology, applied in the field of absorbable dura mater repair patch and its preparation, can solve the problems of anti-leakage and limited mechanical properties, slow absorption, etc., to protect brain tissue, improve cell growth, and promote The effect of cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

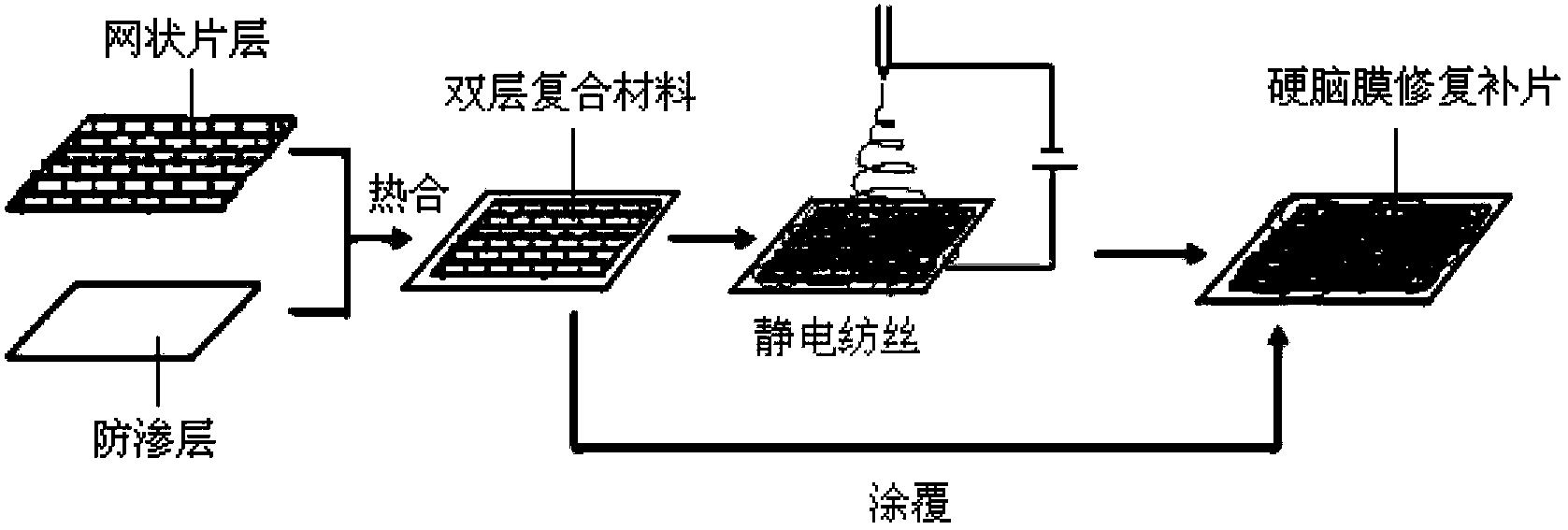

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of anti-seepage layer

[0044] Put polydioxanone in a hot press, turn on the heater of the hot press for heating, and heat press at an absolute pressure of 60MPa and a temperature of 100°C for 20s to obtain a 20mm×20mm×0.05mm anti-seepage layer;

[0045] Under the absolute pressure of 100-155mmHg, the permeability of the anti-seepage layer to physiological saline was measured, and the results showed that the anti-seepage layer remained impermeable for 1 minute under 100-155mmHg;

[0046] 2. Preparation of mesh sheet

[0047] Use a braiding machine to weave the linear materials lactic acid-glycolic acid copolymer and polydioxanone with a diameter of 0.05mm in a horizontal and vertical direction to form a mesh sheet of 20mm×20mm×0.1mm;

[0048] Adopt GB / T 1040-2:2006 method to measure the tensile strength and the elongation at break of the mesh sheet, the results are shown in Table 1;

[0049] 3. Preparation of double-layer composite materials

[0050] ...

Embodiment 2

[0055] 1. Preparation of anti-seepage layer

[0056] Put trimethylene carbonate-glycolide copolymer in a hot press, turn on the heater of the hot press for heating, and heat press for 10s at an absolute pressure of 30MPa and a temperature of 130°C to obtain a 60mm×40mm× 0.1mm anti-seepage layer, the anti-seepage layer remains impermeable for 1 minute under 100-155mmHg;

[0057] 2. Preparation of mesh sheet

[0058] Use a braiding machine to weave the linear materials lactide trimethylene carbonate copolymer and polydioxanone with a diameter of 0.1mm in a crosswise and vertical way to form a mesh sheet of 60mm×40mm×0.2mm; The tensile strength and elongation at break results of the mesh sheet are shown in Table 1;

[0059] 3. Preparation of double-layer composite materials

[0060] Use a heat sealing machine to heat seal the above-prepared anti-seepage layer and mesh sheet at an absolute pressure of 30 MPa and a temperature of 120 ° C for 20 seconds to obtain a composite mate...

Embodiment 3

[0065] 1. Preparation of anti-seepage layer

[0066] The dried p-dioxanone-lactide copolymer particles are fed into the extruder, and through plasticizing extrusion, forming tube blanks, inflation molding, cooling, pulling and other processes, the 80mm×60mm× 0.05mm anti-seepage layer, in which the extrusion temperature is controlled at 140°C and the pulling speed is 3 m / min; the prepared anti-seepage layer remains impermeable for 1 minute at 100-155mmHg;

[0067] 2. Preparation of mesh sheet

[0068] Use a knitting machine to weave linear materials lactic acid-glycolic acid copolymer and polydioxanone with a diameter of 0.05mm in a horizontal and vertical direction to form a mesh sheet of 80mm×60mm×0.1mm; the mesh sheet The results of tensile strength and elongation at break are shown in Table 1;

[0069] 3. Preparation of double-layer composite materials

[0070] Use a heat sealing machine to heat seal the above-prepared anti-seepage layer and mesh sheet at an absolute pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com