Magnetic nanometer oxidized graphene and preparation method and application thereof

A magnetic nanometer and graphene technology, applied in the field of applied chemistry and biochemical industry, can solve the problems of polluted environment and difficult separation, and achieve the effect of high catalytic efficiency, high dispersion and excellent catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

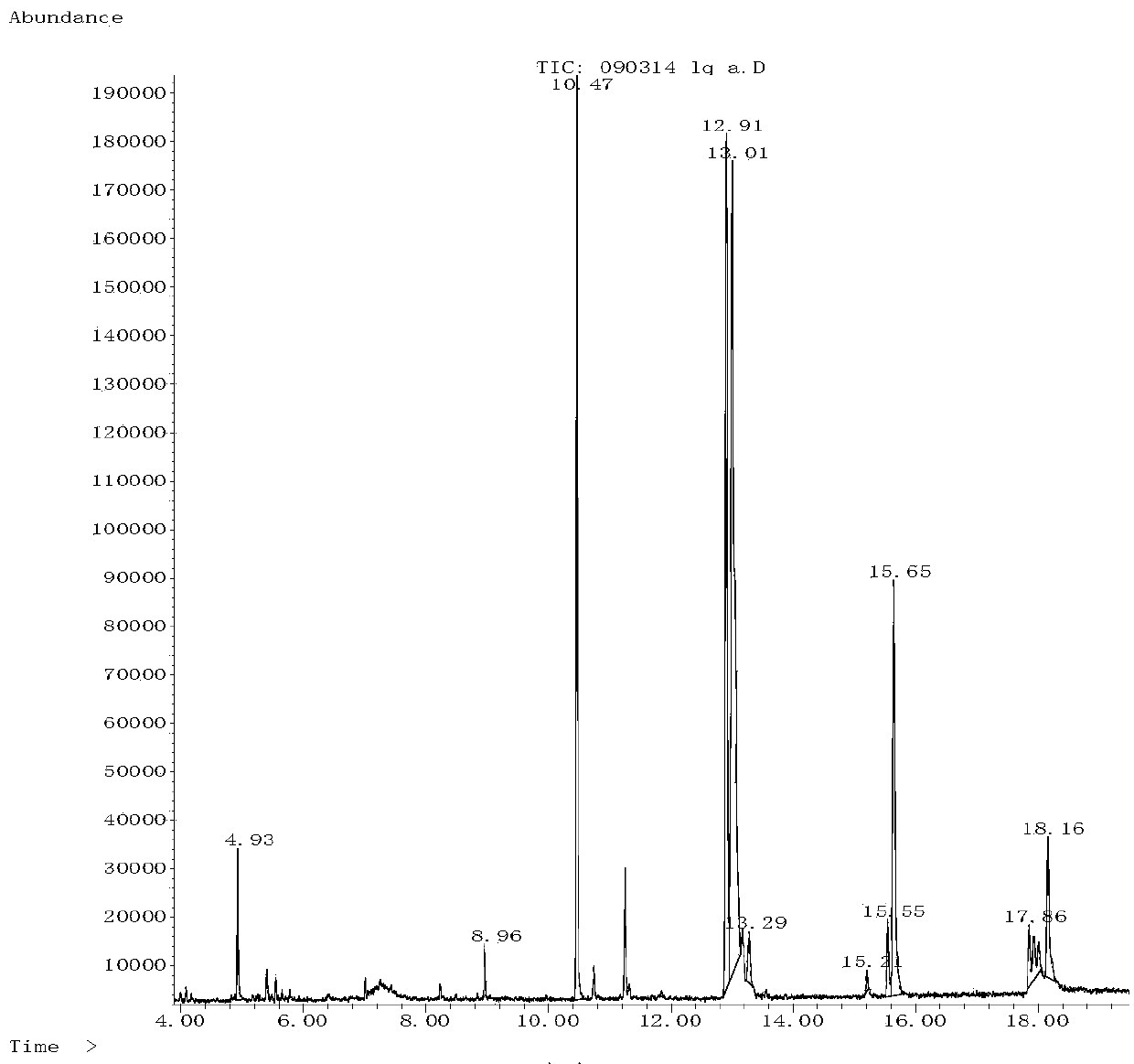

Image

Examples

Embodiment 1

[0025] Embodiment 1: Improved Hummers method prepares graphene oxide

[0026] The improved Hummers method prepares the steps of graphene oxide as follows:

[0027] 1) Low-temperature reaction: Measure 23mL of concentrated sulfuric acid and pour it into a beaker, put the beaker in an ice bath and cool it below 4°C, weigh 1g of graphite powder and 0.5g of sodium nitrate into the beaker, add 3g of high manganese slowly after 1h Potassium acid, then put the beaker on a magnetic stirrer, control the temperature not to exceed 10°C, and the reaction time is 2 hours in total;

[0028] 2) Medium-temperature reaction: After the low-temperature reaction is completed, move the above beaker to a constant temperature water bath, control the temperature of the water bath at 38°C, react for 0.5h, and keep stirring moderately to obtain a brown mixture;

[0029] 3) High temperature reaction: Slowly add 80ml of distilled water to the obtained brown mixture, keep the temperature of the mixture a...

Embodiment 2

[0032] Embodiment 2: the method 1 of the preparation of magnetic nano graphene oxide

[0033] The preparation method of magnetic nano-graphene oxide is as follows: dry the graphene oxide prepared in step 1), grind it to a fine powder, weigh 6 mg and disperse it in 6 ml of water, and ultrasonically oscillate for 0.5 h to obtain a graphene oxide solution. Ferrous sulfate was dissolved into the graphene oxide solution, and 0.001 g of surfactant SDS was added at the same time, and exposed to the air for 0.5 hours. Then under strong stirring conditions, 1mol / L NaOH was added dropwise to PH>9, the stirred suspension was black, and the reaction product iron ferric oxide nanoparticles were formed to load on the surface of graphene, the reaction product was filtered, and then washed with a large amount of distilled water, It was dried in a freeze dryer to obtain magnetic nano graphene oxide.

Embodiment 3

[0034] Embodiment 3: the method 2 of the preparation of magnetic nano graphene oxide

[0035] The preparation method of magnetic nano-graphene oxide is as follows: dry the graphene oxide prepared in step 1), grind it to a fine powder, weigh 6 mg and disperse it in 10 ml of water, and ultrasonically oscillate for 1 hour to obtain a graphene oxide solution. Dilute 1 g of sulfurous acid Iron was dissolved into the graphene oxide solution while adding 0.002 g of surfactant SDS and exposed to air for 0.5 h. Then under strong stirring conditions, 1mol / L NaOH was added dropwise to PH>9, the stirred suspension was black, and the reaction product iron ferric oxide nanoparticles were formed to load on the surface of graphene, the reaction product was filtered, and then washed with a large amount of distilled water, It was dried in a freeze dryer to obtain magnetic nano graphene oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com