Preparation method of nitrogen doping titanium dioxide powder, prepared titanium dioxide powder material and purpose thereof

A titanium dioxide and nitrogen doping technology, applied in chemical instruments and methods, physical/chemical process catalysts, applications, etc., can solve the problems of high cost, effective nitrogen doping, difficult to obtain, etc., and achieve good crystallinity and small particle size. , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

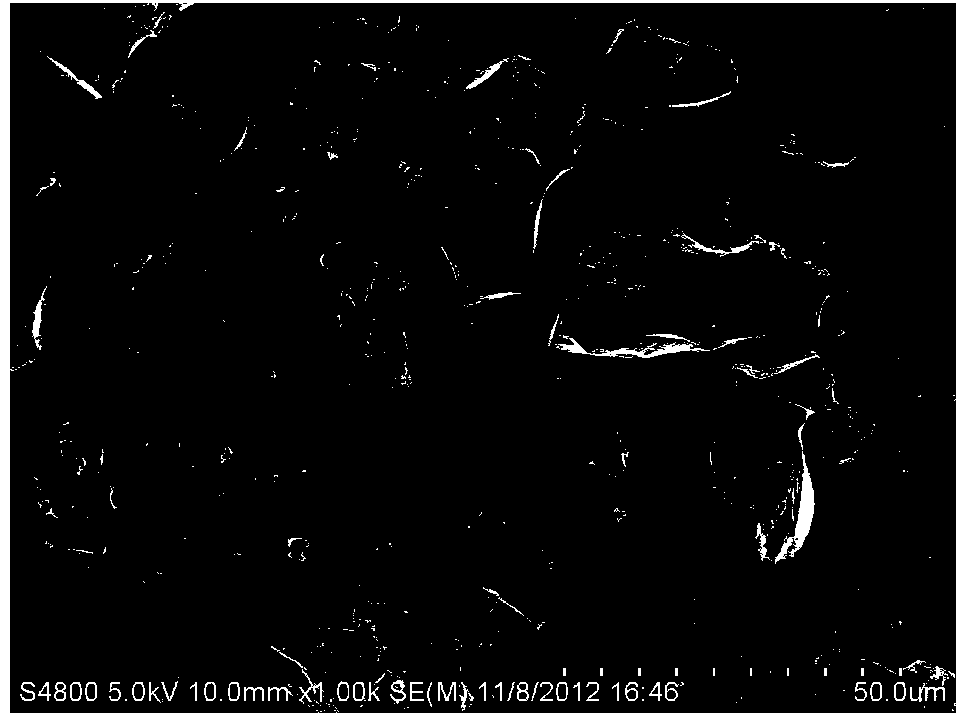

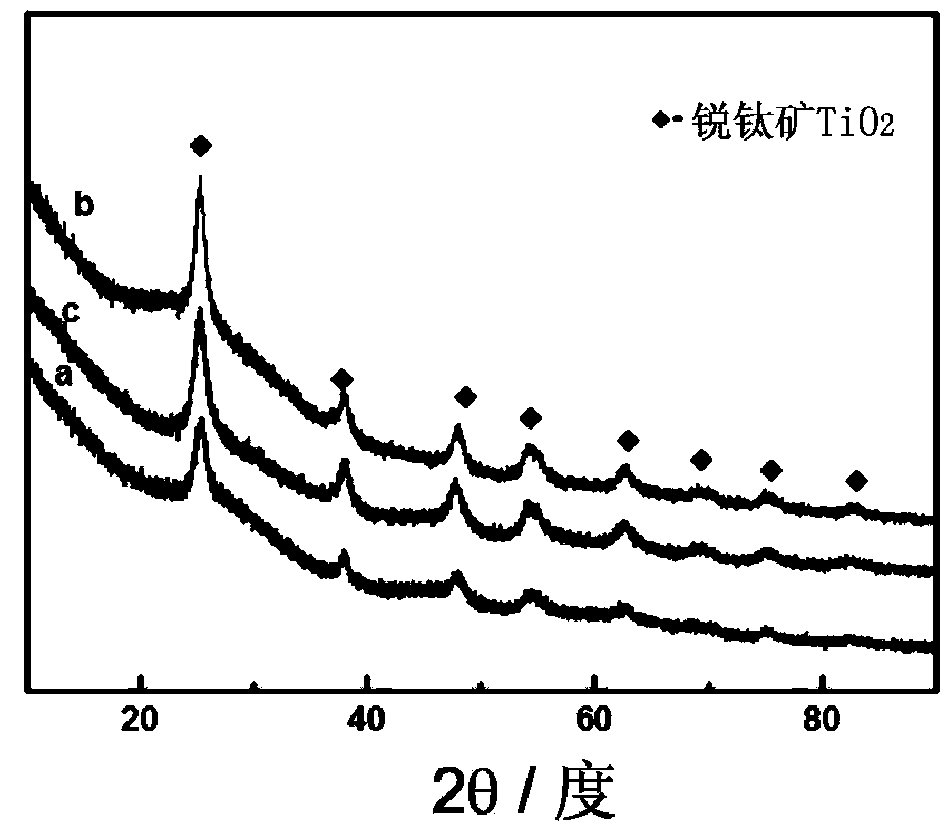

[0033] Dissolve 1 part by volume of tetrabutyl titanate in 10 parts by volume of acetic acid, and stir at room temperature for 24 hours to obtain a gel, then place the gel in a drying oven at 80°C for 12 hours, and dry grind for 1 hour to obtain Precursor powder. Carry out SEM test to the precursor powder prepared in this embodiment, the photo is as figure 1 shown. Take 0.4g of precursor powder, and press it in the axial direction at room temperature and 10MPa (forming a disc with a diameter of 10mm and a thickness of 1mm), and then undergo cold isostatic pressing at 180MPa to obtain the precursor block. Then, the precursor block was implanted between the mantle and the shell of the spinosa clam as a bead nucleus, and the nucleated spinosa clam was put into fresh water for cultivation. After 45 days of cultivation, it was taken out of the spinosa clam. A bead core that has been coated with nacre. Remove the pearl layer grown on the surface of the bead nucleus to obtain a li...

Embodiment 2

[0037] Dissolve 2 parts by volume of tetrabutyl titanate in 10 parts by volume of acetic acid, and stir at room temperature for 24 hours to obtain a gel, then place the gel in a drying oven at 80°C for 12 hours, and dry grind for 2 hours to obtain Precursor powder. Take 0.8g of precursor powder, and press it in the axial direction at room temperature and 11MPa (forming a disc with a diameter of 10mm and a thickness of 2mm), and then press it through cold isostatic pressing at 180MPa to obtain the precursor block. Then, the precursor block was implanted between the mantle and the shell of the spinosa clam as a bead nucleus, and the nucleated spinosa clam was put into fresh water for cultivation. After 90 days of cultivation, it was taken out of the spinosa clam. A bead core that has been coated with nacre. Remove the pearl layer grown on the surface of the bead nucleus to obtain a light yellow block, and then grind to obtain a light yellow powder. The ground light yellow powd...

Embodiment 3

[0040] Dissolve 3 parts by volume of tetrabutyl titanate in 10 parts by volume of acetic acid, and stir at room temperature for 24 hours to obtain a gel, then place the gel in a drying oven at 80°C for 12 hours, and dry grind for 0.5 hours, Get the precursor powder. Take 2g of precursor powder, and press it in the axial direction at room temperature and 15MPa (forming a disc with a diameter of 20mm and a thickness of 1.2mm), and then press it through cold isostatic pressing at 180MPa to obtain the precursor block. Then, the precursor block was implanted between the mantle and the shell of the spinosa clam as a bead core, and the cored spinosa clam was put into fresh water for cultivation. After 60 days of cultivation, it was taken out from the body of the spinosa clam. A bead core that has been coated with nacre. Remove the pearl layer grown on the surface of the bead nucleus to obtain a light yellow block, and then grind to obtain a light yellow powder. The ground light yel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com