Al-NaBiO3 composite materials used for hydrogen generation by hydrolysis and preparation thereof

A composite material and hydrogen production technology by hydrolysis, applied in the field of high-activity aluminum-based composite materials for mobile hydrogen sources, can solve the problems of high starting temperature of aluminum-water reaction and unsustainable reaction, and achieve low raw material price, light weight, and improved reaction active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Under the protection of argon, the mass distribution is m(Al):m(NaBiO 3 ) = 0.9:0.1 aluminum and sodium bismuthate components are added to the steel ball milling tank, select the ball milling parameters with a rotating speed of 500 rpm and a ball-to-material ratio of 60:1, and place the ball milling tank on the QM-3SP2 planetary ball mill High-speed ball milling, ball milling for 10 hours to obtain a highly active hydrolysis hydrogen production composite material with uniform composition.

[0031] Weigh 0.05g sample into the reaction bottle, seal it well and add different proportions of deionized water. The hydrogen gas produced in the experiment was introduced into an inverted measuring cylinder filled with water through a catheter, and the data was recorded manually with a stopwatch. By changing the experimental temperature, the hydrolysis hydrogen release performance of the sample at room temperature and different temperatures was obtained.

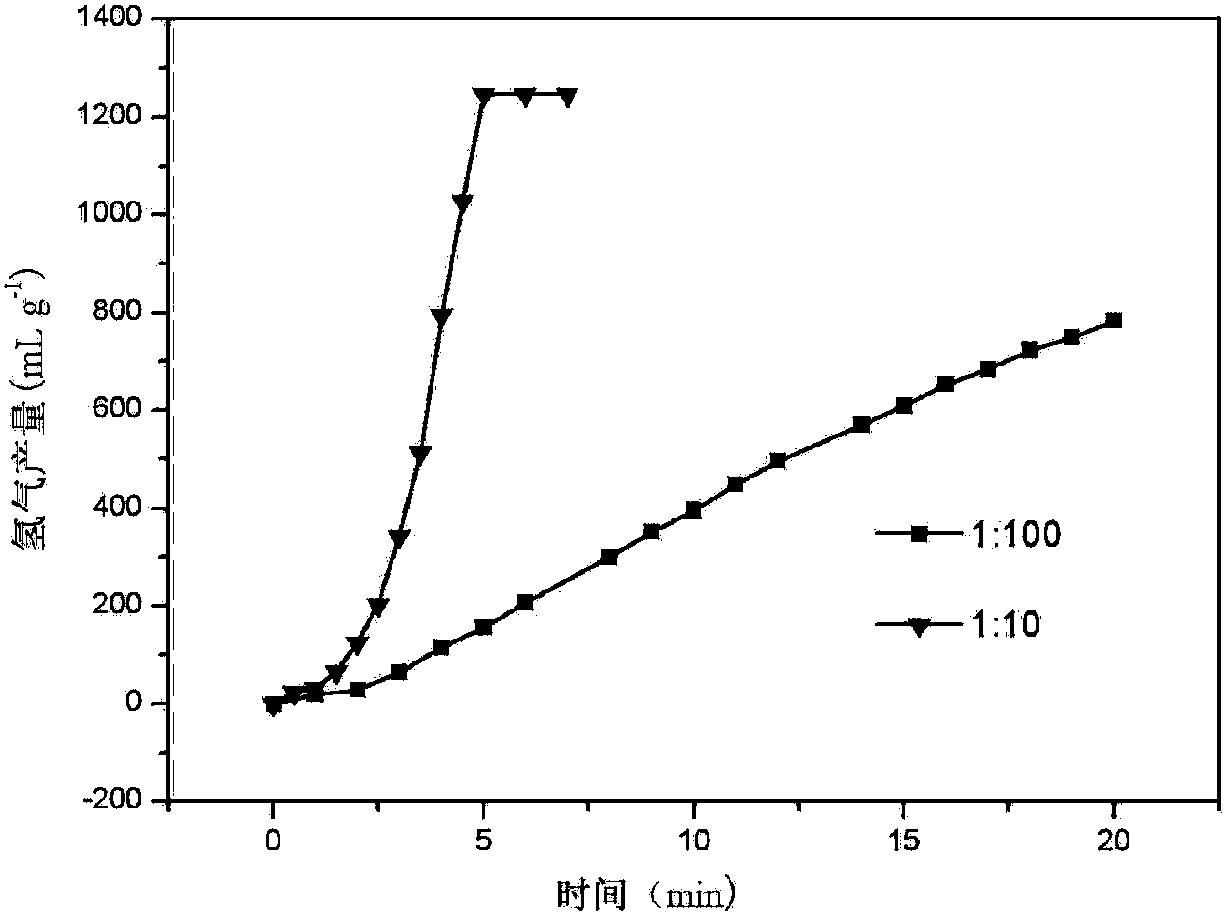

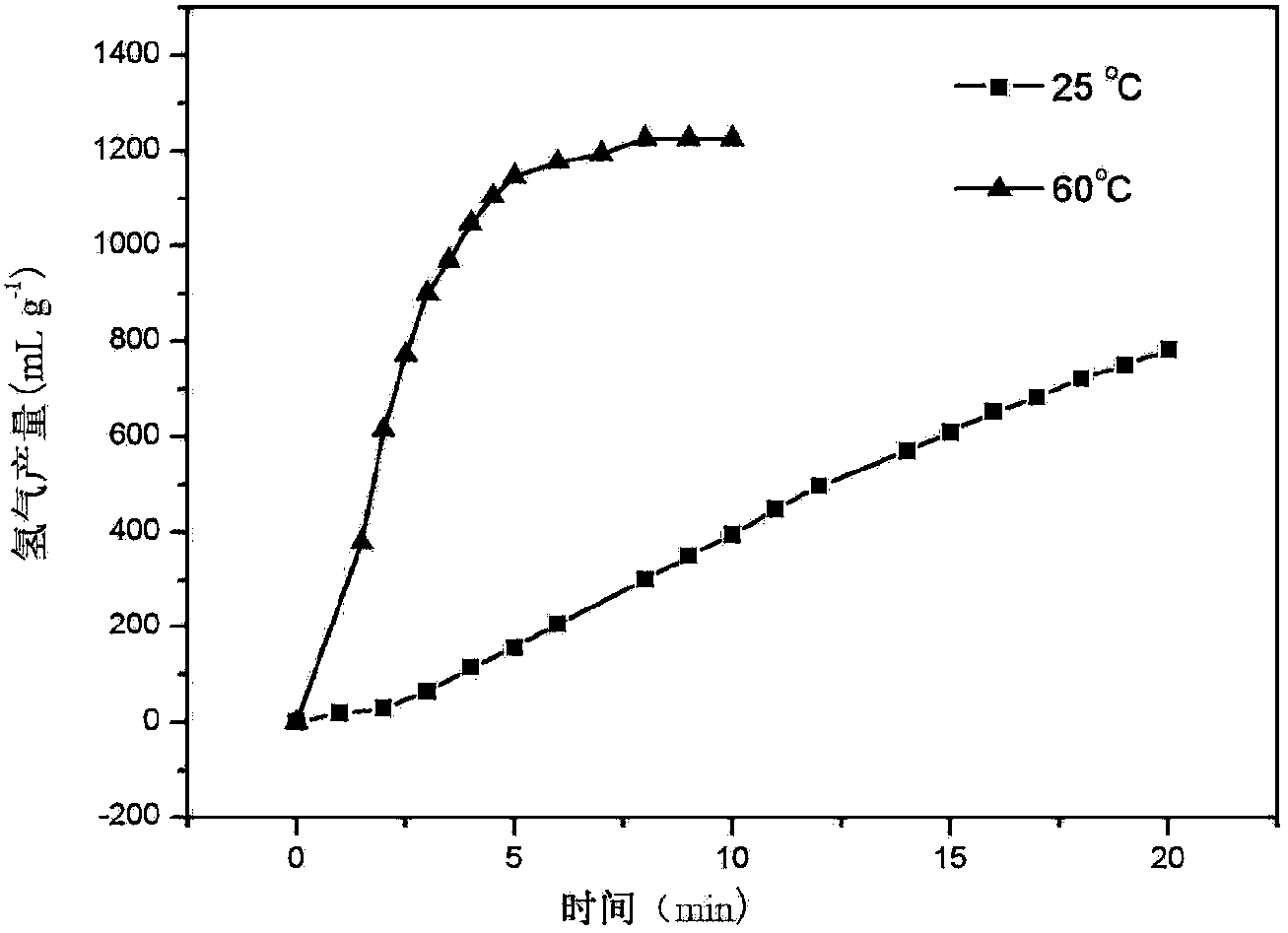

[0032] Depend on figu...

Embodiment 2

[0034] Under the protection of argon, the mass distribution is m(Al):m(NaBiO 3 )=0.9:0.1 aluminum and sodium bismuthate components were added to the steel ball mill jar, and the ball mill parameters were consistent with Example 1.

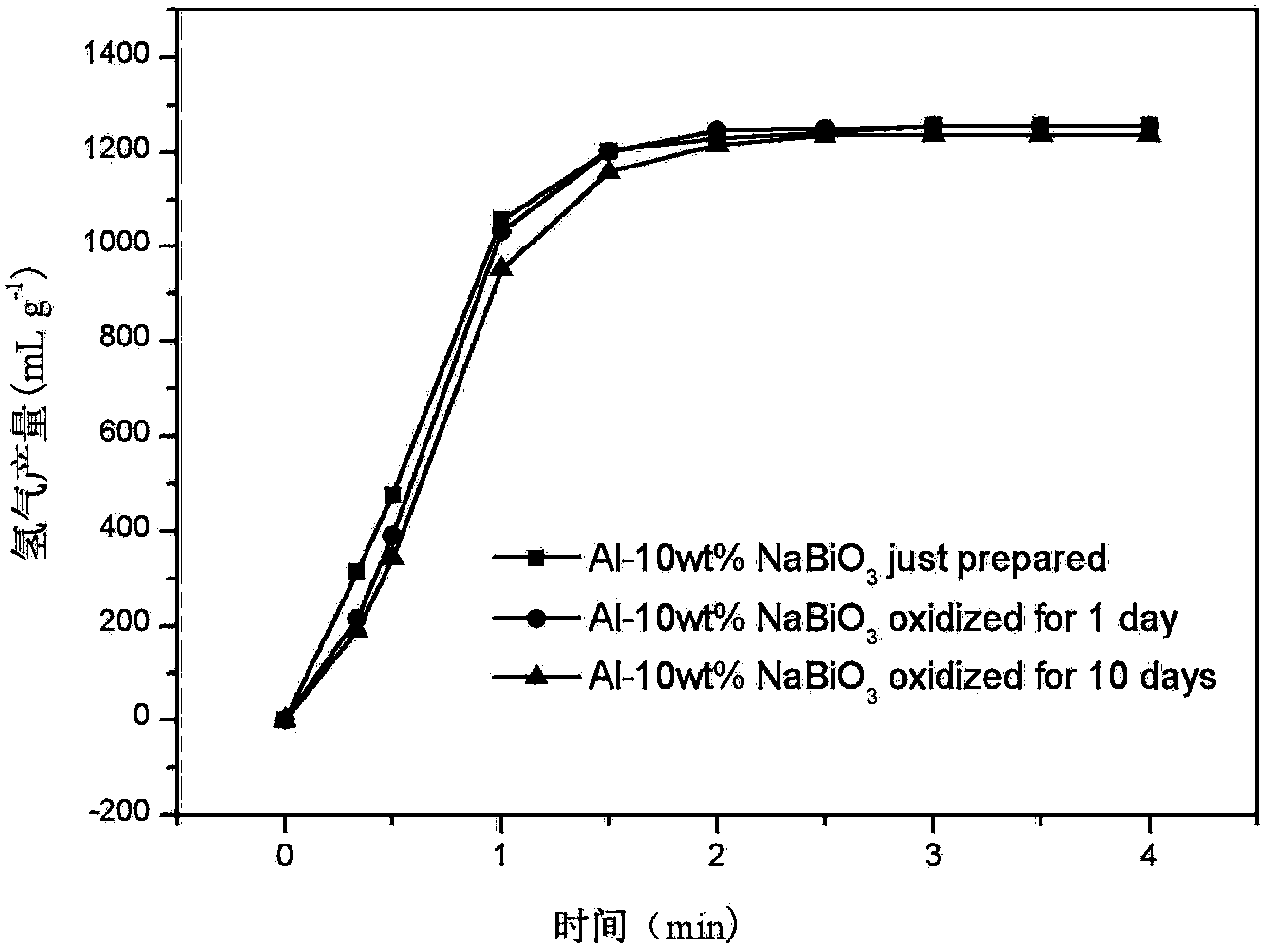

[0035] After the composite material sample is obtained, place it open in the air, make it fully contact with water and oxygen in the air for different times, weigh 0.05g sample into the reaction bottle, seal it and add 5mL deionized water, sample test method Consistent with Example 1.

[0036] Depend on image 3 It can be seen that Al-NaBiO 3 The composite material has excellent oxidation resistance in the air, and the hydrogen desorption performance still does not decrease significantly after being placed in the air at room temperature for ten days.

Embodiment 3

[0038] Under argon protection, aluminum and sodium bismuthate components in different mass ratios were added into a steel ball mill jar, and the ball mill parameters were consistent with those in Example 1. Weigh 0.05g of sample into the reaction bottle, seal it and add 5mL of deionized water. The sample testing method is consistent with that of Example 1.

[0039] Depend on Figure 4 It can be seen that Al-NaBiO 3 Hydrogen release performance of composites increased with NaBiO 3 increased rapidly with the increase of doping amount, indicating that NaBiO 3 It is a very effective dopant for activating aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com