Method for fractionating grease through using erythritol fatty acid ester, and application of erythritol fatty acid ester

A technology of erythritol and fatty acid ester, which is applied in the field of oil fractionation and can solve problems such as failure to obtain ideal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

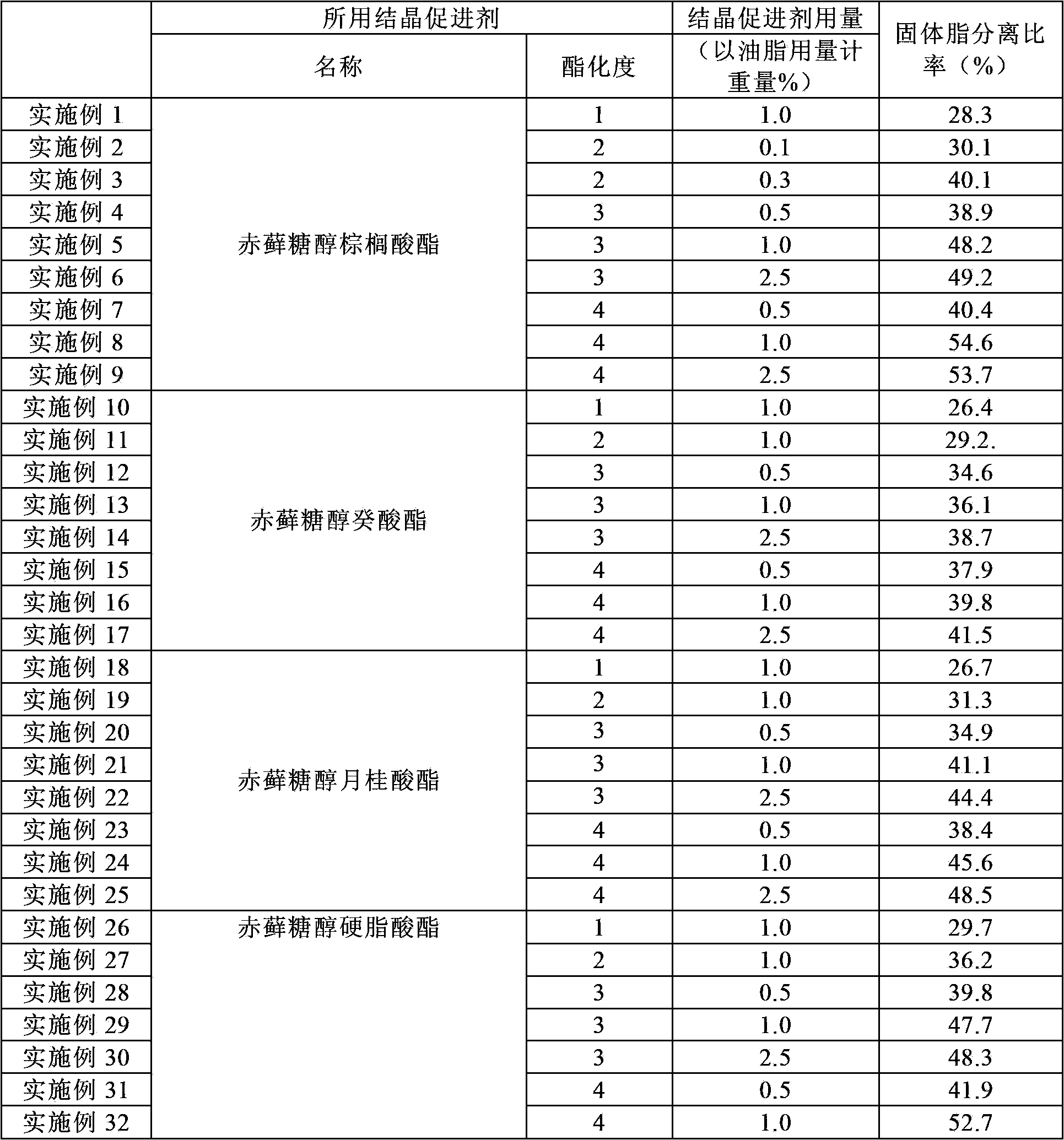

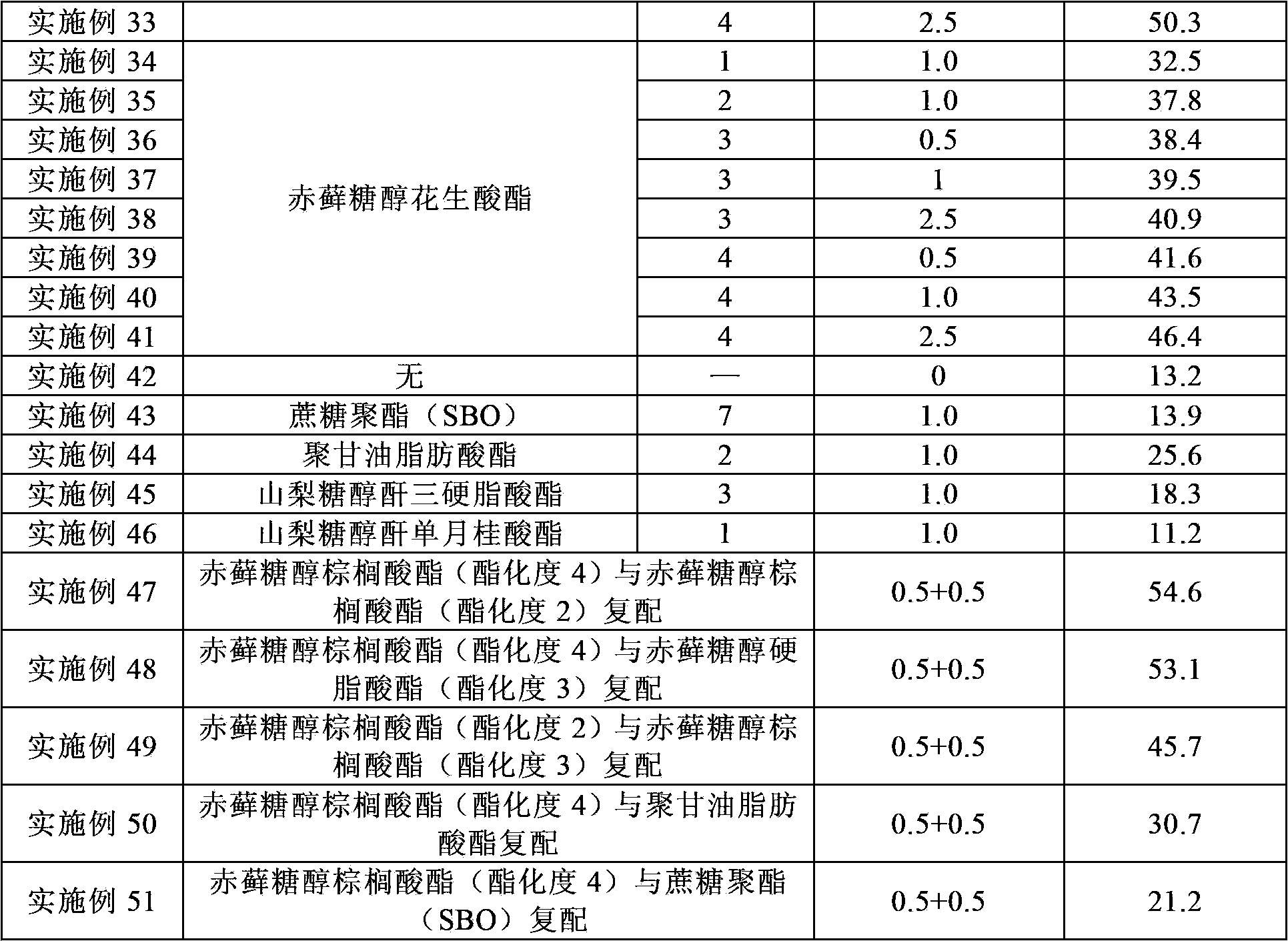

Examples

Embodiment

[0034] A. Preparation and characterization of erythritol fatty acid esters with different degrees of esterification

preparation Embodiment i

[0037] Preparation Example i: Preparation of Erythritol Monopalmitate

[0038] Weigh 105 grams (0.41 moles) of palmitic acid and 150 grams (1.23 moles) of erythritol into a 2-liter three-necked flask, and install a reflux condenser, a mechanical stirrer and an addition funnel for the flask. 1 liter of cyclohexane was added to the flask as a reflux solvent, followed by phase transfer catalyst cetyltrimethylammonium bromide (7.65 g, 3% by weight) and reaction catalyst p-toluenesulfonic acid (5.1 g, 2% by weight). Start the stirring device, heat the mixture to 95°C, and reflux at this temperature for 8 hours. After the reaction is over, filter while hot to remove unreacted erythritol, cool to room temperature, let it stand for 1 hour, and extract it with a Buchner funnel. Filter, wash with 1500 ml of saturated aqueous sodium bicarbonate solution, then wash with 800 ml of petroleum ether, and dry at room temperature in a vacuum oven to obtain 80 g of the product. Use petroleum e...

preparation Embodiment ii

[0039] Preparation Example ii: Preparation of Erythritol Palmitic Acid Diester

[0040] In this experiment, the reaction system, nuclear magnetic resonance instrument and HPLC in the above preparation example i were used. Take by weighing 210 grams (0.82 moles) of palmitic acid and 50 grams (0.41 moles) of erythritol and add in the there-necked flask, add 1 liter of toluene as reflux solvent in this flask, then add reaction catalyst p-toluenesulfonic acid (7.8 grams, 3% by weight). The mixture was refluxed at 130°C for 24 hours. After the reaction was completed, unreacted erythritol was removed by filtration while it was hot, cooled to room temperature, allowed to stand for 1 hour, and suction filtered with a Buchner funnel. Washing, and then washing with 1200 milliliters of petroleum ether, after drying at room temperature in a vacuum oven, 220 grams of product were obtained. Use petroleum ether as a solvent, add the product to petroleum ether according to the ratio of prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com