Complex microbial inoculant for broiler chickens and application thereof to improvement of broiler chicken productivity and immunity

A compound bacterial agent and broiler chicken technology, applied in the direction of application, microbial-based methods, biochemical equipment and methods, etc., can solve problems such as rough meat quality, lack of flavor, and overfat broiler carcasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1, the preparation of composite bacterial agent for broilers

[0078] This example relates to two kinds of composite bacterial agents for broilers, which are composite bacterial agents A for broilers and composite bacterial agents B for broilers.

[0079] Composite microbial agent A for broilers is to dilute the liquid strains of Bacillus subtilis RJGP16, Saccharomyces cerevisiae CICC1562 and Lactobacillus plantarum CICC22696 to 10 8 After cfu / ml, the mixture was mixed according to the colony-forming unit number ratio of 1:3:1.

[0080] The compound bacterial agent B for broilers is to dilute the liquid strains of Bacillus subtilis RJGP16, Saccharomyces cerevisiae CICC1562 and Lactobacillus plantarum CICC22696 to 10% respectively with sterile water. 8 After cfu / m1, the mixture was mixed according to the colony-forming unit number ratio of 1:1:1.

[0081] Wherein, the liquid strain of Bacillus subtilis RJGP16 is a culture obtained by culturing with fermentat...

Embodiment 2

[0085] Embodiment 2, the preparation of broiler probiotics

[0086]This example provides two kinds of probiotics for broiler chickens, respectively called probiotics A for broilers and probiotics B for broilers.

[0087] The probiotics A for broilers is a culture obtained by using the fermentation medium A of Example 1 to cultivate the composite microbial agent A for broilers of Example 1. The specific preparation method is as follows: the broiler composite bacterial agent A of embodiment 1 is inserted into the 200L embodiment according to the inoculum amount (the volume of the composite bacterial agent inserted and the volume ratio of the fermentation medium) of 6% (volume ratio). In a 500L fermenter of fermentation medium A of 1, cultivate for 42 hours at 34°C, with an aeration rate of 600L / h and a stirring speed of 150rpm, collect all the cultured substances (fermentation liquid) in the fermenter, and add The rice husk powder was dried at 50° C. to obtain the probiotic pre...

Embodiment 3

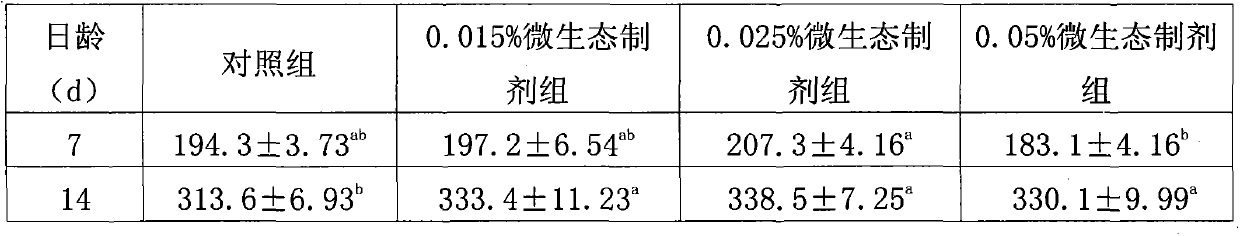

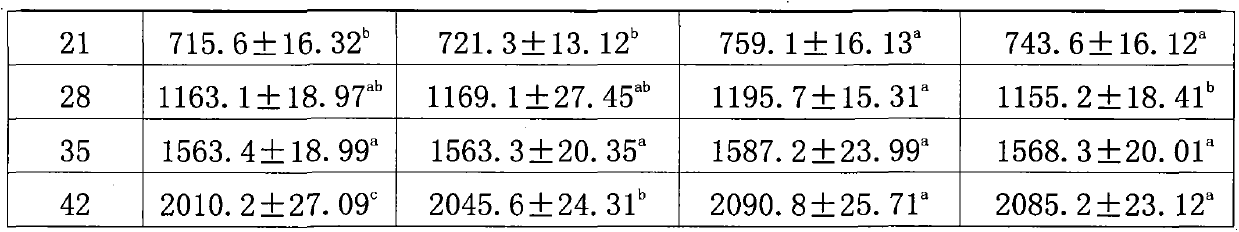

[0089] Embodiment 3, improve broiler body weight with the broiler chicken probiotic A of embodiment 2

[0090] 1.1 Test animals

[0091] Select 12,000 1-day-old healthy chicks of Arboriga—Quick large white-feathered broiler chicken with a body weight of 50±5 grams, and divide them into 4 treatment groups at random, namely, the control group, the 0.015% probiotics group, and the 0.025% probiotics group. Ecological preparation group and 0.05% probiotic preparation group. There were 3 replicates per treatment group with 1000 chickens per replicate.

[0092] 1.2 Diet

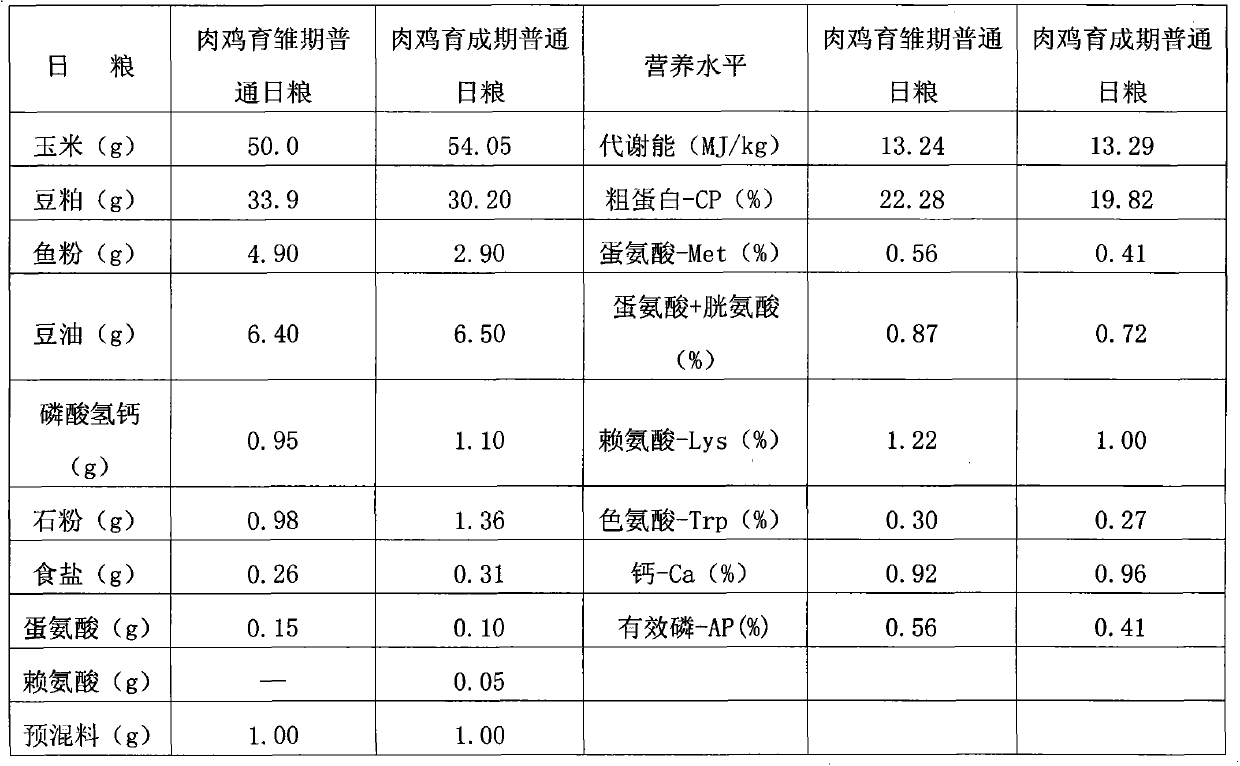

[0093] Broiler brooding period diets were divided into broiler brooding period common rations, 0.015% broiler probiotics A brooding rations, 0.025% broiler probiotics A brooding rations, 0.05% broiler probiotics A brooding rations. Among them, the common diet for broiler brooding period is shown in Table 1; 0.015% broiler chicken probiotics A brooding period diet is added to the common diet for broiler chicken br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com