Nitrogen-rich porous carbon desulfurizer and preparation method thereof

A technology of desulfurization agent and porous carbon, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of low content of nitrogen-containing functional groups and achieve rich nitrogen-containing functional groups, improved desulfurization capacity, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

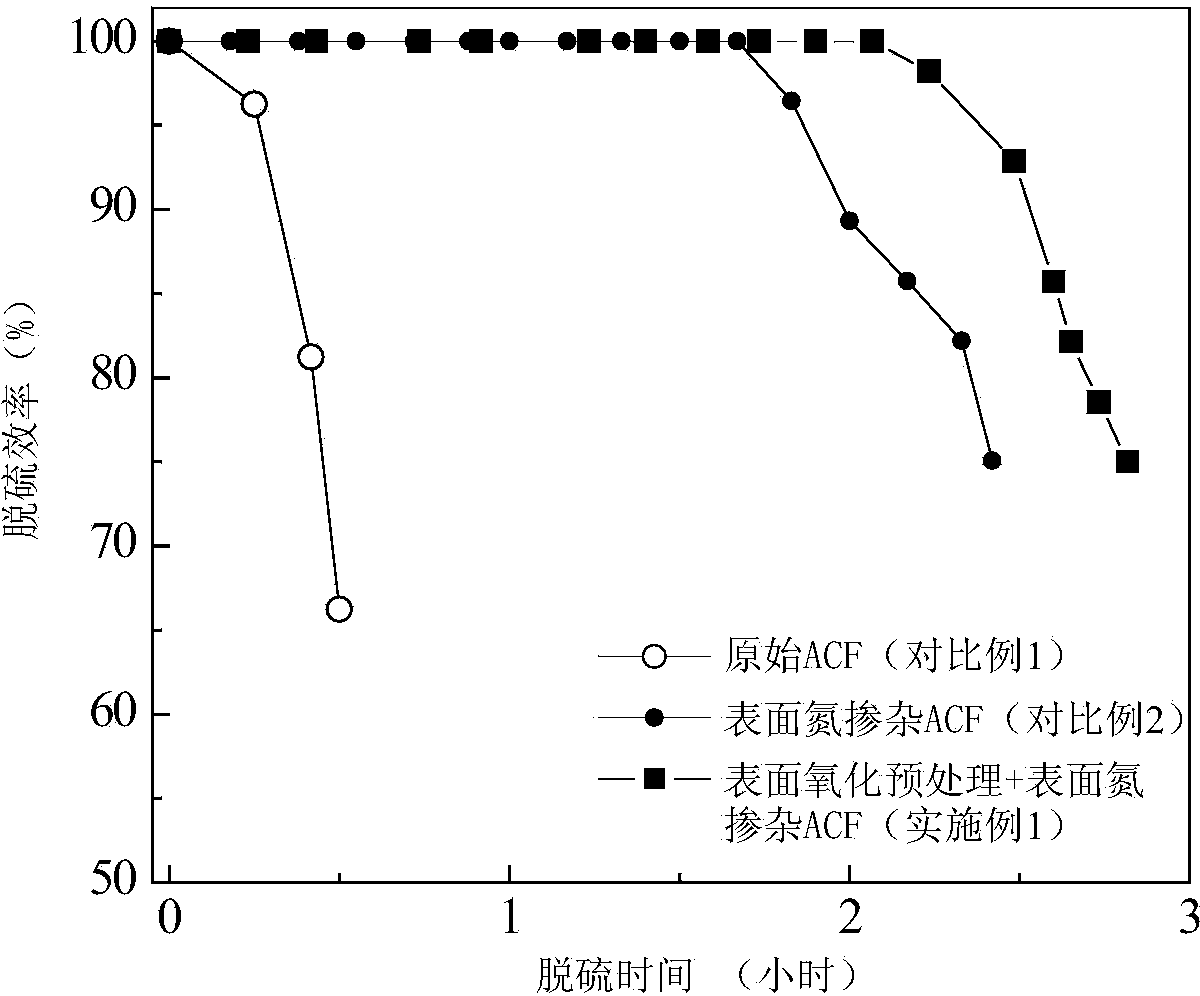

Embodiment 1

[0033] Soak the activated carbon fiber in a nitric acid solution with a mass concentration of 30%, stir it in a constant temperature water bath at 60°C for 2 hours, take it out, rinse the activated carbon fiber with deionized water to pH=6-7, and then dry it in an oven at 105°C overnight . Dissolve 100 grams of dicyandiamide in 200 milliliters of ethanol solution with a mass concentration of 50% to form a dicyandiamide solution. Pour 100 grams of acid-washed activated carbon fibers into the above-mentioned dicyandiamide solution, heat while stirring at 60° C., slowly evaporate ethanol and moisture, and then dry overnight at 105° C. in an oven. Put the activated carbon fiber loaded with dicyandiamide into a high-temperature calcination furnace, under the condition of nitrogen protection, raise the temperature from room temperature to 750°C at a rate of 5°C / min, and keep it at 750°C for 1 hour, then cool Finally, a nitrogen-rich activated carbon fiber desulfurizer with dicyandi...

Embodiment 2

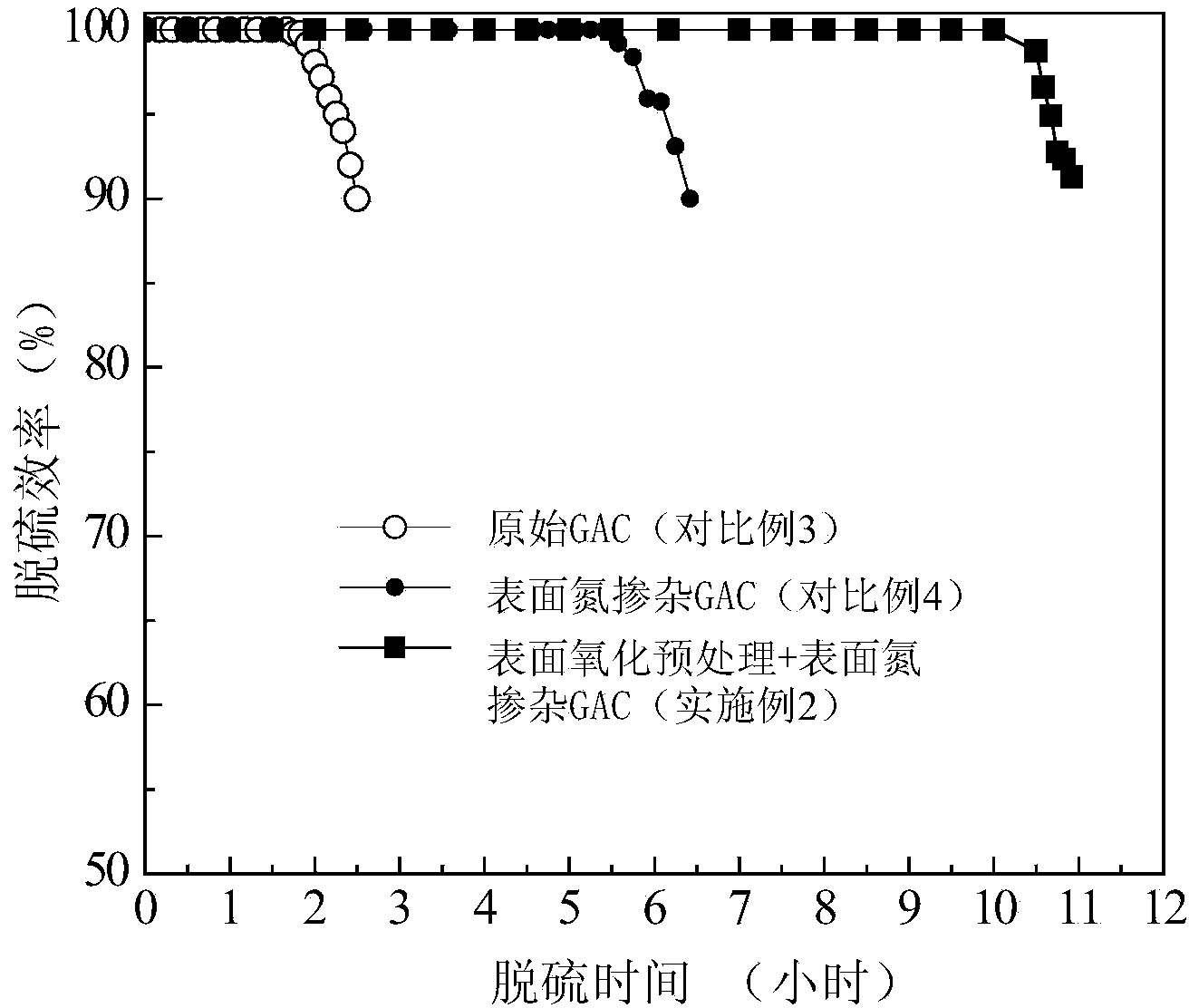

[0041] Soak 10-20 mesh granular activated carbon in a nitric acid solution with a mass concentration of 20%, and stir in a constant temperature water bath at 60°C for 3 hours. The acid-washed granular activated carbon was rinsed with deionized water to pH=6-7, and then dried overnight in an oven at 105°C. Dissolve 5 grams of melamine in 100 milliliters of water to make a melamine solution. Pour 30 grams of acid-washed 10-20 mesh granular activated carbon into the above-mentioned melamine solution, heat while stirring at 60°C, slowly evaporate the water, and then dry in an oven at 105°C overnight. The granular activated carbon loaded with melamine was placed in a high-temperature calciner, and under the condition of nitrogen protection, the temperature was raised from room temperature to 800 °C at a heating rate of 5 °C / min, and kept at 800 °C for 1 hour. After cooling, the following Nitrogen-rich granular activated carbon desulfurizer with melamine as nitrogen source and surf...

Embodiment 3

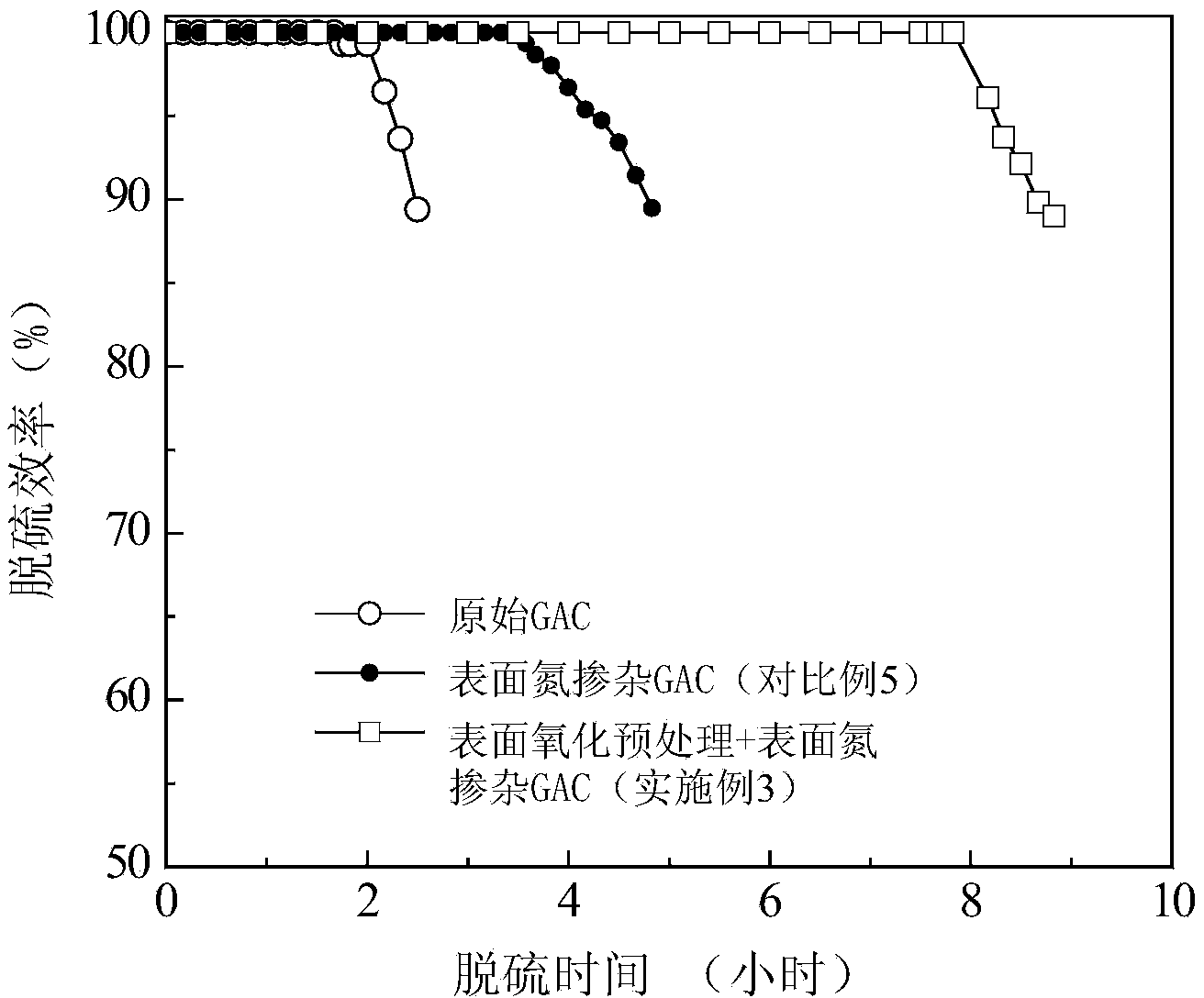

[0049] Soak 10-20 mesh granular activated carbon in a nitric acid solution with a mass concentration of 50%, and react at 60°C for 1 hour. The acid-washed granular activated carbon was rinsed with deionized water to pH=6-7, and then dried overnight in an oven at 105°C. Dissolve 200 grams of urea in 1000 milliliters of 50% ethanol aqueous solution to form a urea solution. Pour 100 grams of acid-washed granular activated carbon into the above-mentioned urea solution, heat while stirring at 60°C, slowly evaporate ethanol and water, and then dry in an oven at 105°C overnight. The activated carbon loaded with urea was placed in a high-temperature calciner, and under the condition of nitrogen protection, the temperature was raised from room temperature to 850 °C at a heating rate of 5 °C / min, and kept at 850 °C for 1 hour. After cooling, urea was obtained. Nitrogen-enriched granular activated carbon desulfurizer with surface nitrogen doping as nitrogen source.

[0050] Elemental a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakthrough sulfur capacity | aaaaa | aaaaa |

| Breakthrough sulfur capacity | aaaaa | aaaaa |

| Breakthrough sulfur capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com