Preparation method of glass fiber titanium-dioxide-loaded composite material

A glass fiber, composite material technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as unfavorable practical applications, complex preparation methods, etc., to achieve low cost and improve photocatalytic efficiency. , to achieve the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.01M ammonium nitrate to 100mL0.5M nitric acid solution and stir evenly to obtain a mixed solution, add 0.2M titanium source titanium trichloride to the mixed solution under ice bath conditions, and finally obtain a transparent homogeneous solution;

[0024] Add the obtained solution to 0.1g single fiber form A-glass fiber, raise the temperature to 70°C, react for 6 hours, adjust the pH value to 7 with urea as an alkaline reagent, and after aging for 12 hours, wash and dry to obtain a composite material ;

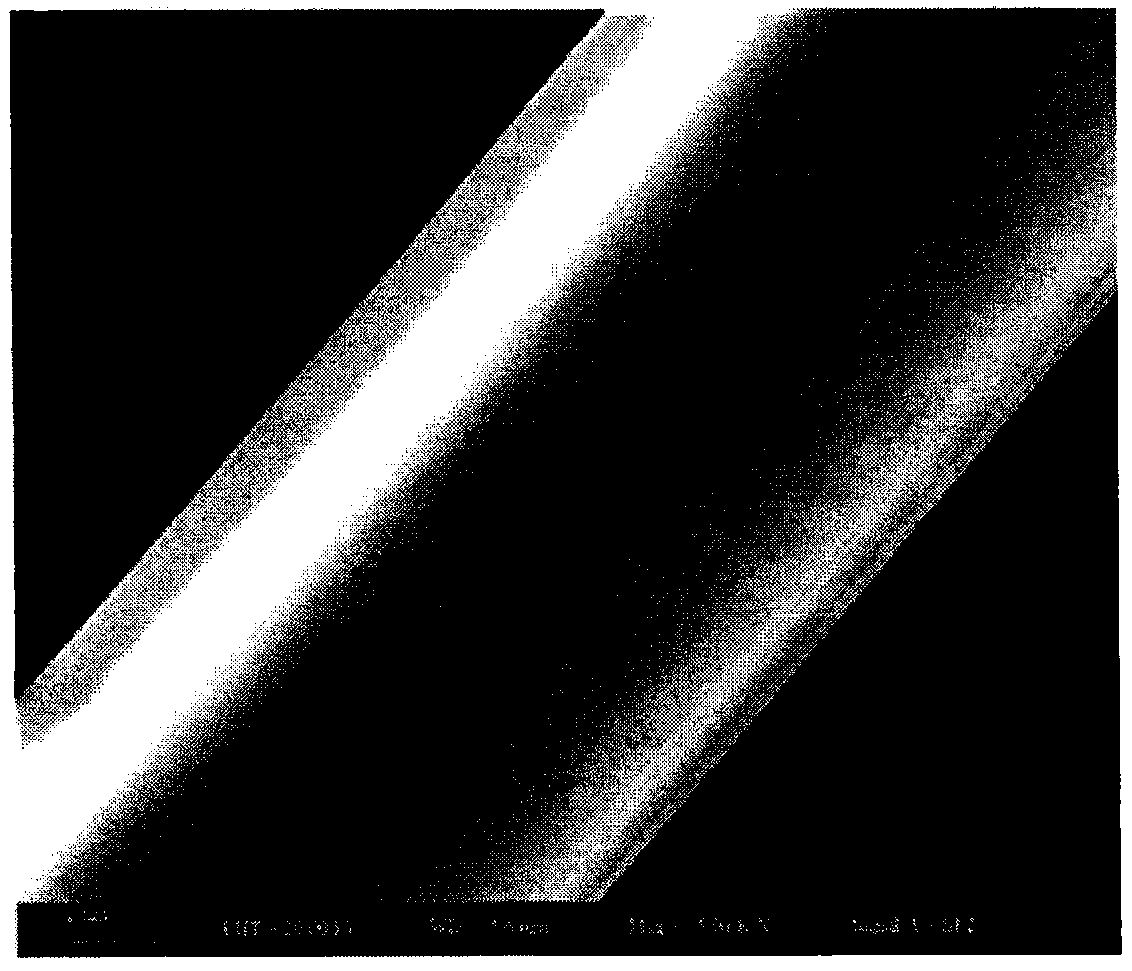

[0025] The obtained composite material is heated up to 600° C. at a temperature of 1° C. / minute in air, kept for 2 hours, and then heat-treated to obtain a glass fiber-supported nano-scale titanium dioxide composite material.

Embodiment 2

[0027] Add 1M ammonium chloride to 100mL of 0.01M hydrochloric acid solution and stir evenly to obtain a mixed solution. Add 0.5M titanium source ammonium fluorotitanate to the mixed solution under ice bath conditions to finally obtain a transparent homogeneous solution;

[0028] Add 2 g of E-glass fibers in the form of short fibers to the solution, raise the temperature to 120°C, and react for 1 hour, then adjust the pH value to 7 with an alkaline reagent as sodium hydroxide solution, and after aging for 12 hours, wash and dry. get composite materials;

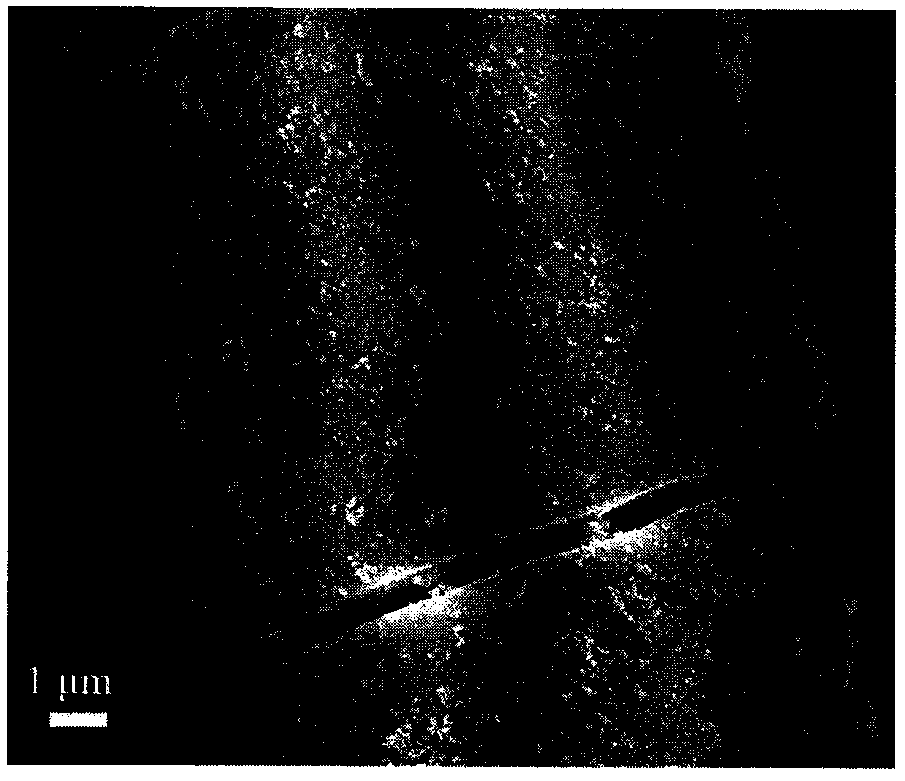

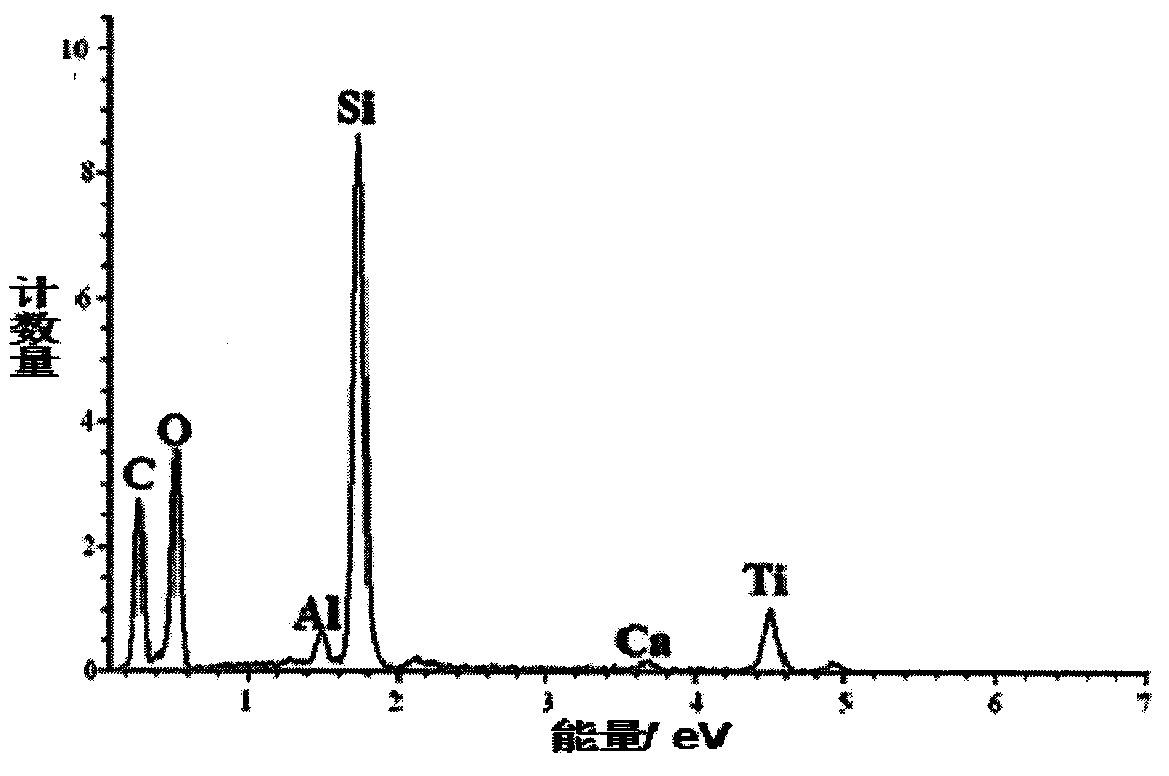

[0029] The obtained composite material was heated in the air at a temperature of 5 °C / min to 300 °C, kept for 2 hours, and then heat-treated to obtain a glass fiber / titanium dioxide composite material with a regular helical structure. Its appearance and element composition are as follows: figure 2 with image 3 shown.

Embodiment 3

[0031] Add 3M ammonium sulfate to 100mL of 1M sulfuric acid solution and stir evenly to obtain a mixed solution. Add 0.4M titanium tetrachloride as a titanium source to the mixed solution under ice bath conditions to finally obtain a transparent and uniform solution;

[0032] Add 5g of C-glass fibers in bundled form to the solution, raise the temperature to 100°C, react for 5 hours, the reaction is complete, adjust the pH value to 7 with urea as an alkaline reagent, and after aging for 12 hours, wash and dry. get composite materials;

[0033] The obtained composite material was heated up to 200°C at a temperature of 2°C / min in the air, kept for 2 hours, and then heat-treated to obtain a glass fiber-loaded titanium dioxide composite material with a spherical structure. Its appearance is as follows: Figure 4 shown;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com