Preparation method and application of bi-metal cyanide catalyst

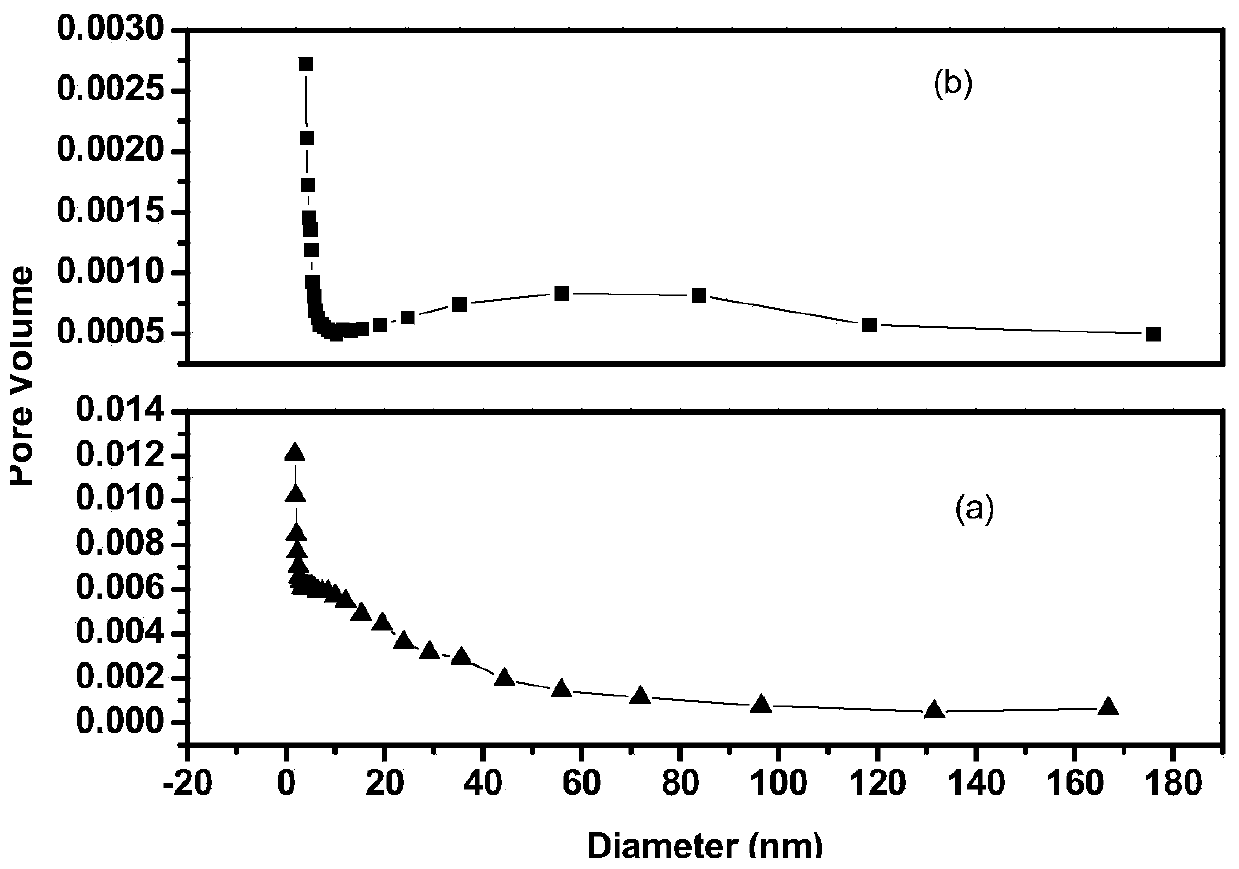

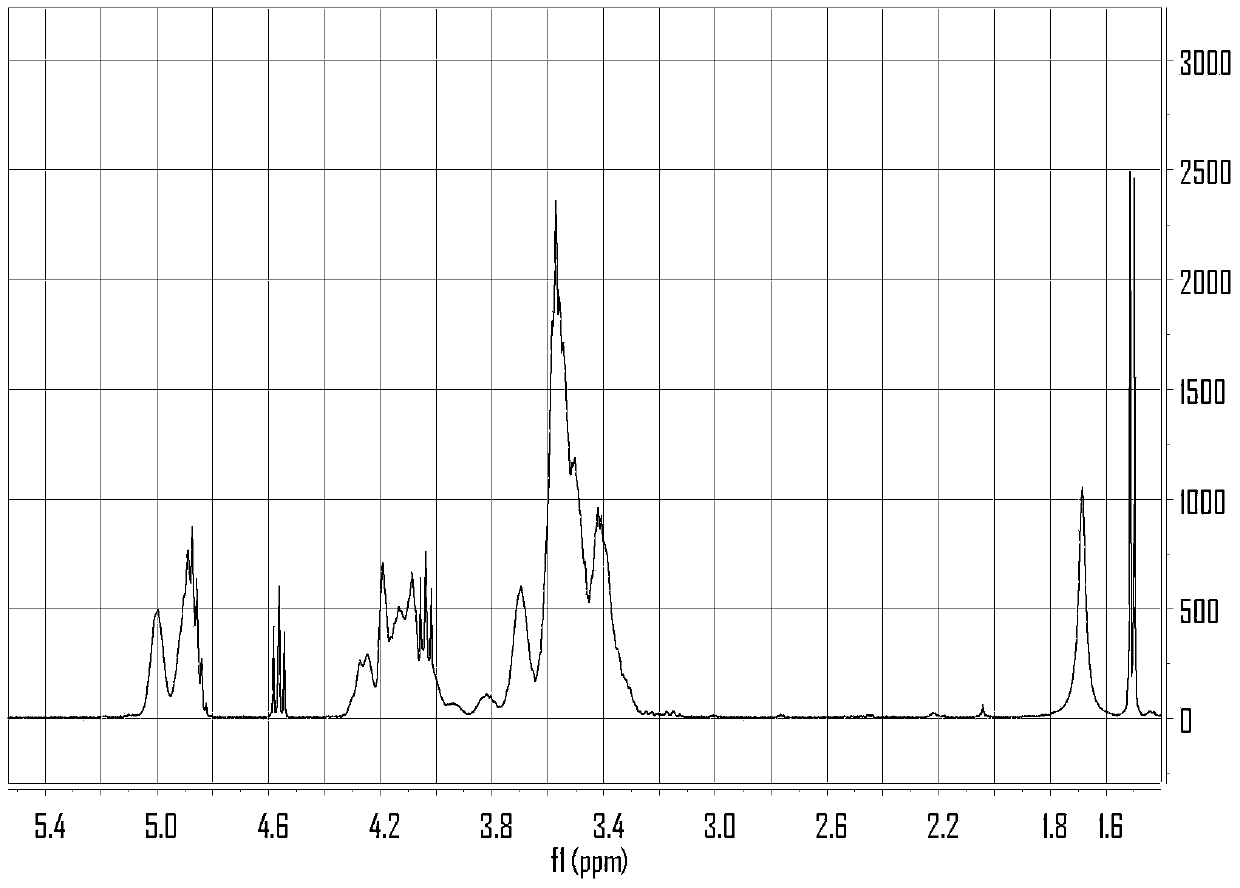

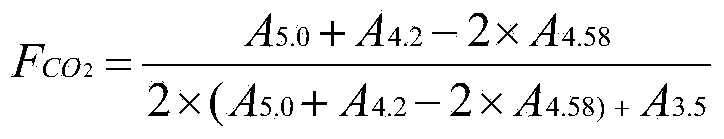

A double metal cyanide and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low carbon dioxide insertion and low catalyst activity, and achieve wide pore size distribution and activity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Weigh 10g of potassium hexacyanocobaltate(III) into a 250mL three-necked flask, add 50mL of deionized water, 90mL of TritonX-100, 50mL of tert-butanol, and 60mL of cyclohexane, and stir for 2 hours at 2000r / min to obtain Uniform and transparent microemulsion. Weigh 40g ZnCl 2 In a 1L three-neck flask, add 100mL of deionized water, 180mL of TritonX-100, 100mL of tert-butanol and 120mL of cyclohexane, and stir at 2000r / min for 2h to obtain a uniform microemulsion. Transfer the potassium hexacyanocobaltate(III) microemulsion to a 300mL separatory funnel, and add it dropwise to the ZnCl 2 In the microemulsion, the temperature was controlled at 30°C. After the dropwise addition was completed, stirring was continued for 2 h. By measurement, the average particle diameter of the emulsion after mixing is 15nm. The resulting solution was demulsified and centrifuged under the condition of 9000r / min, the precipitate was put into a 1L three-necked flask, a mixed solution of 200m...

Embodiment 2

[0062] Weigh 10g of potassium hexacyanoferrate(Ⅲ) into a 250mL three-neck flask, add 50mL of deionized water, 90mL of tetrabutylphosphine bromide, 50mL of ethylene glycol monomethyl ether, and 60mL of dimethyl ether, Stir for 2 hours under the same conditions to obtain a uniform and transparent microemulsion. Weigh 40g of zinc sulfate into a 1L three-neck flask, add 100mL of deionized water, 180mL of tetrabutylphosphine bromide, 100mL of dimethyl ether and 120mL of ethylene glycol monomethyl ether, and stir for 2 hours under the condition of 2000r / min to obtain a uniform Microemulsion. Transfer the potassium hexacyanoferrate (III) microemulsion to a 300mL separatory funnel, and add it dropwise into the zinc sulfate microemulsion under the stirring condition of 2000r / min, and the temperature is controlled at 30°C. After the dropwise addition was completed, stirring was continued for 2 h. By measurement, the average particle diameter of the emulsion after mixing is 16nm. The ...

Embodiment 3

[0064] Weigh 10g of potassium hexacyanocobaltate (Ⅲ) into a 250mL three-neck flask, add 50mL of deionized water, 90mL of lecithin, 50mL of dimethyl ether, and 60mL of petroleum ether, and stir for 2 hours at 2000r / min to obtain a uniform Microemulsion. Weigh 40g ZnBr 2 In a 1L three-neck flask, add 100mL of deionized water, 180mL of lecithin, 100mL of dimethyl ether and 120mL of petroleum ether, and stir at 2000r / min for 2h to obtain a uniform microemulsion. Transfer the potassium hexacyanocobaltate (Ⅲ) microemulsion to a 300mL separatory funnel, and add it dropwise to the ZnBr under the stirring condition of 2000r / min. 2In the microemulsion, the temperature was controlled at 30°C. After the dropwise addition was completed, stirring was continued for 2 h. By measurement, the average particle diameter of the emulsion is 16nm. The resulting solution was demulsified and centrifuged under the condition of 9000r / min, the precipitate was put into a 1L three-necked flask, a mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com