Nitrogen and phosphorus removal advanced treatment method for wastewater

A technology for advanced treatment, denitrification and dephosphorization, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. Meet water quality discharge standards, unstable treatment effects, etc., and achieve the effects of low operating costs, easy maintenance and management, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

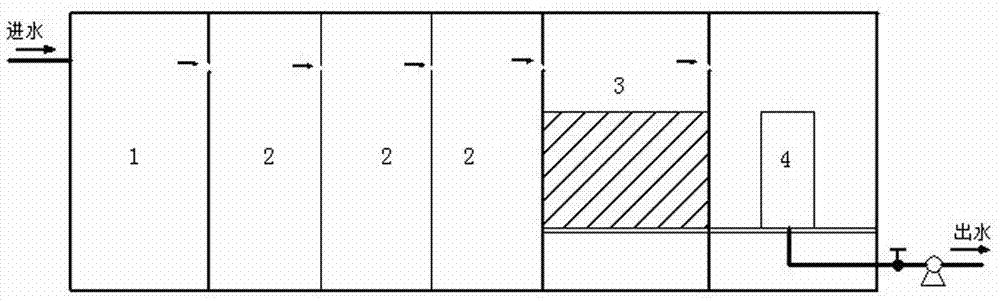

[0030] Such as figure 1 As shown, the sewage containing 20mg / L of ammonia nitrogen, 10mg / L of phosphorus, and 300 mg / L of COD is passed into the pretreatment tank, and polyacrylamide with a molecular weight of 12 million is added in an amount of 1-5ppm of the sewage; Place it for 2 hours to remove the sediment, and the clean sewage enters the algae membrane bioreactor divided into 4 sections. Each section of the reactor has Chlorella pyrenoidosa, Anabaena blooms and Coleopsis algae, and the light intensity is 3000lux; from the end of the reactor A section of outflow water enters the inclined plate sedimentation tank, and polyacrylamide with a molecular weight of 12 million is added, and the amount of addition is 1ppm of the water volume, and it is left to stand for 2 hours. The suspended solids are deposited and discharged uniformly through the sludge collection system at the bottom of the pool. Filtrate with a tubular polyamide filter membrane module, the pore size of the polya...

Embodiment 2

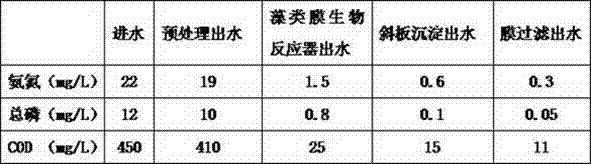

[0032] Such as figure 1 As shown, the sewage containing 23mg / L of ammonia nitrogen, 12mg / L of phosphorus, and 320 mg / L of COD is passed into the pretreatment tank, and polyacrylamide with a molecular weight of 10 million is added in an amount of 1-5ppm of the amount of sewage; Set aside for 3 hours to remove the sediment, and the clean sewage enters the algae membrane bioreactor divided into 6 sections. Each section of the reactor is planted with Chlorella pyrenoidosa, Anabaena blooms, Coleopsis, Scenedesmus obliquus, and Oscillating algae. and water net algae; the light intensity is 3200lux; the water flowing out from the last section of the reactor enters the inclined plate sedimentation tank, and polyacrylamide with a molecular weight of 10 million is added in an amount of 2ppm of the water amount, and the suspended matter is deposited after standing for 3 hours , discharged through the sludge collection system at the bottom of the pool, and the clean water is filtered with...

Embodiment 3

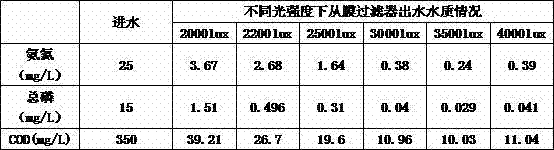

[0034] Such as figure 1 As shown, the sewage containing 25mg / L of ammonia nitrogen, 15mg / L of phosphorus, and 350 mg / L of COD is passed into the pretreatment tank, and cationic polyacrylamide with a molecular weight of 6 million is added, and the amount of addition is 1-5ppm of the amount of sewage; Stand for 4 hours, remove the sediment, and the clean sewage enters the algae membrane bioreactor divided into 8 sections. The first 4 sections of the reactor are planted with Chlorella pyrenoidosa, Anabaena blooms, Coleopsis, Scenedesmus obliquus, A. Oscillating algae and Hydroreticula, the last four stages are Chlorella pyrenoidosa, Anabaena blooms and Coleoptera; the light intensity is 3200lux; the water flowing out from the last stage of the reactor enters the inclined plate sedimentation tank, and the added molecular weight is 6 million The cationic polyacrylamide is added in an amount of 3ppm of the water, and after standing for 4 hours, the suspended solids are deposited and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com