Conductive adhesive for over-temperature overcurrent protective element and production method thereof

A technology for protecting components, over-temperature and over-current, applied in the direction of electrical components, conductive adhesives, circuits, etc., can solve problems such as occupying a large volume, unable to meet surface mount requirements, etc., and achieve improved safety factor and circuit safety protection Enhanced action and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

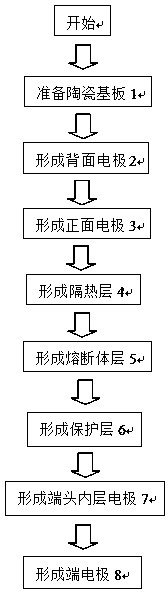

Method used

Image

Examples

Embodiment 1

[0051] The addition ratio of all raw materials is calculated based on the weight of low melting point alloy powder;

[0052] a. Put the low-melting alloy powder with an average particle size of 10 μm into a 10wt% alkali solution and stir for 5 minutes for alkali washing to remove oil stains on the surface of the alloy powder, then wash with deionization for 3 to 5 times until neutral, and then filter ,drying;

[0053] b. Put the alloy powder obtained in step a into the carbonic acid solution of 1wt% concentration and stir for 5 minutes, carry out pickling, remove the oxide on the surface of the alloy powder, then wash 3 to 5 times with deionized water to neutrality, and then use Rinse once with acetone, filter and dry for later use;

[0054] C, take by weighing silver nitrate according to the 20% proportioning of low-melting-point alloy powder weight, and add deionized water to dissolve, then add the ethylenediamine of 15% of above-mentioned low-melting-point alloy powder wei...

Embodiment 2

[0061] a. Put the low-melting alloy powder with an average particle size of 4 μm into a 15wt% alkali solution and stir for 5 minutes for alkali washing to remove the oil stains on the surface of the alloy powder, then wash with deionization for 3 to 5 times until neutral, and then filter ,drying;

[0062] b. Put the alloy powder obtained in step a into the 0.2wt% concentration of acetic acid solution and stir for 5min, carry out pickling, remove the oxides on the surface of the alloy powder, then wash with deionized water 3 to 5 times until neutral, and then Rinse once with acetone, filter and dry for later use;

[0063] C, take by weighing silver acetate according to the 10% proportioning of low-melting-point alloy powder weight, and add deionized water to dissolve, then add the diethylenetriamine of 25% of above-mentioned low-melting-point alloy powder weight, prepare silver amine solution;

[0064] d, based on the weight of the low-melting point alloy powder, take 0.1% ben...

Embodiment 3

[0071] A conductive adhesive for over-temperature and over-current protection components, which is composed of matrix resin and conductive filler, the matrix resin is epoxy resin, and the conductive filler is low-melting-point alloy metal powder plated with silver on the surface. One of tin-copper alloy, tin-silver-copper alloy, tin-bismuth alloy, tin-bismuth-silver alloy and tin-indium alloy between ℃, the average particle size is 10μm, and the added amount is 50wt by weight %~80wt%

[0072] The preparation method of the conductive adhesive for the above-mentioned over-temperature and over-current protection element comprises the following steps:

[0073] The addition ratio of all raw materials is calculated based on the weight of low melting point alloy powder;

[0074] a. Put the low-melting alloy powder with an average particle size of 20 μm into a 3wt% alkali solution and stir for 5 minutes for alkali washing to remove oil stains on the surface of the alloy powder, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com