Aqueous-phase synthesis method of Cu-doped Zn1-xCdxS quantum dot and core/shell structure thereof

A technology of zn1-xcdxs and quantum dots, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of biological application limitations, inability to directly apply biological imaging, high reaction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

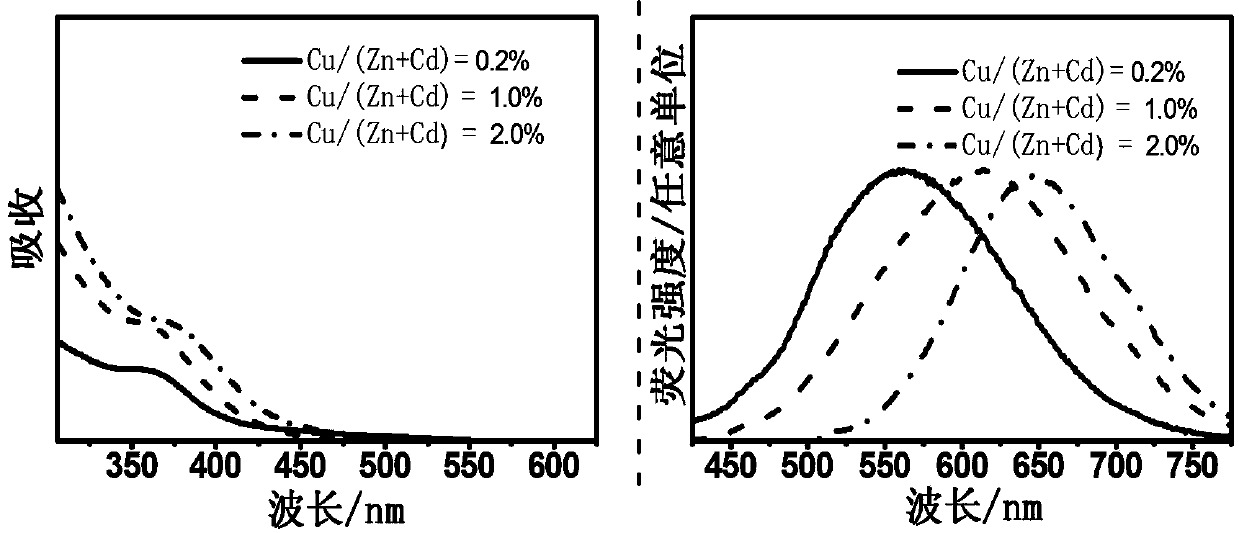

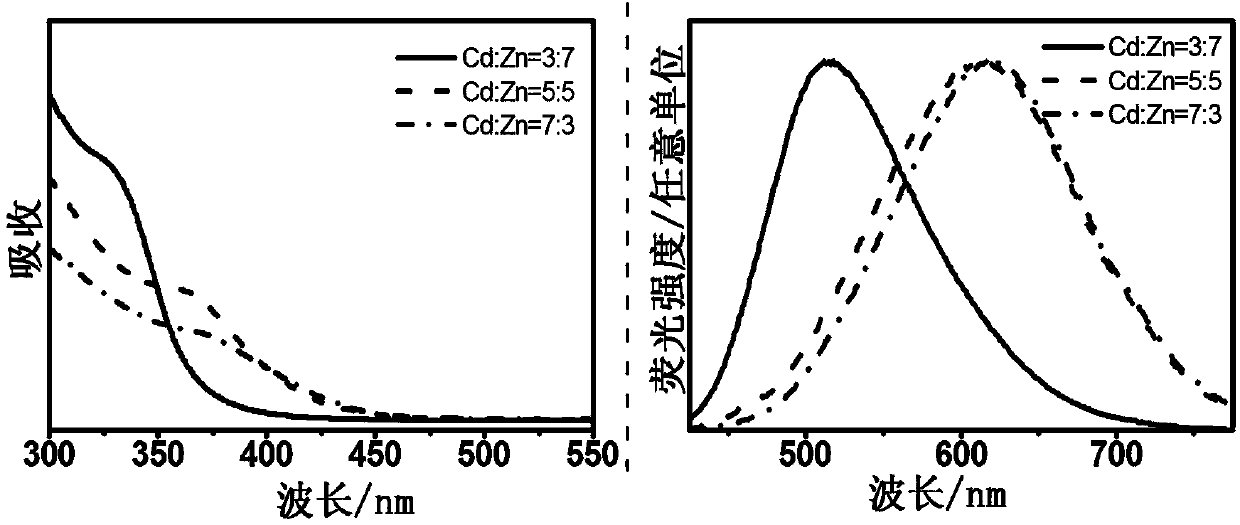

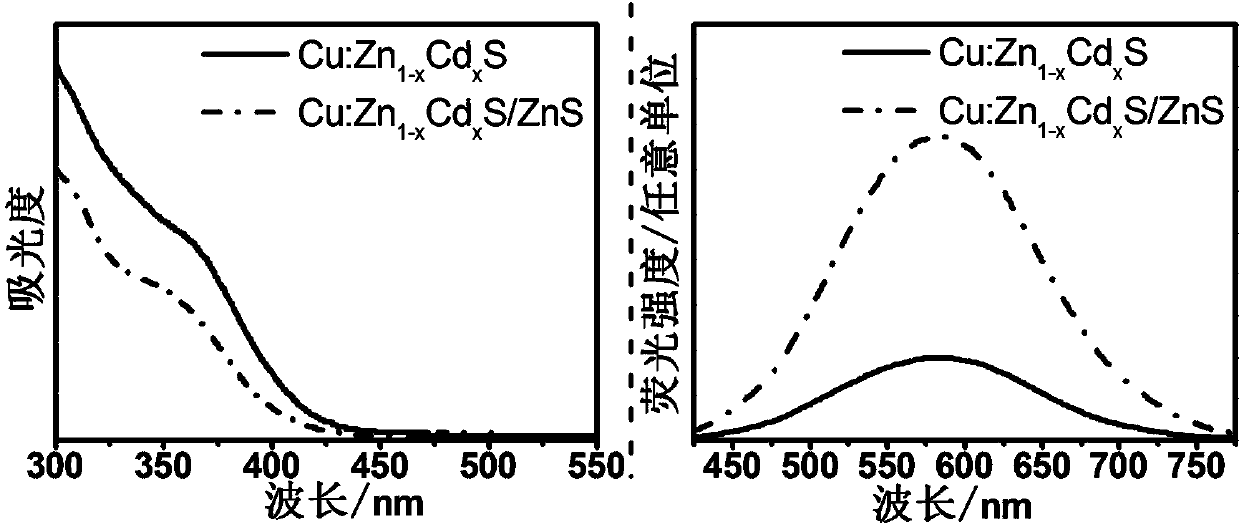

[0022] The reaction solution of sulfur powder and sodium borohydride was used as the sulfur source stock solution, zinc acetate, copper chloride, and cadmium acetate were used as the zinc ion source, copper ion source, and cadmium ion source respectively, and mercaptopropionic acid was used as the mercapto compound to prepare Cu :Zn 1-x Cd x Cu:Zn with core-shell structure formed by S quantum dots and further encapsulation of ZnS 1-x Cd x S / ZnS core / shell quantum dots.

[0023] Step (a): Accurately measure 12 ml of deionized water in the polyethylene liner, add sodium hydroxide to adjust the pH value to 8.5, add 0.0384 g of sulfur powder and 0.15 g of sodium borohydride, and put the polyethylene liner into Just put the kettle on and tighten the lid, react at 180°C for 2 hours, flush with water to cool down, and then make the sulfur source stock solution.

[0024] Step (b): Dissolve 0.104 g of zinc acetate in 4 ml of deionized water, add 0.026 ml of mercaptopropionic acid a...

Embodiment 2

[0029] Example 2 is the same as Example 1, except that the sulfur source stock solution in Example 1 is replaced by a sulfur source stock solution made by dissolving 0.0936 grams of sodium sulfide in 12 milliliters of deionized water.

Embodiment 3

[0031] Embodiment 3 is the same as Embodiment 1, except that the sulfur source stock solution in Embodiment 1 is replaced by directly adopting 0.0152 grams of thiourea as the sulfur source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com