Method for selectively preparing propylene and clean gasoline through using methanol

A selectivity and methanol technology, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and the production of hydrocarbons from oxygen-containing organic compounds. Short time, guaranteed selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 11.76 kg of pseudo-boehmite into the stirred tank, inject 700 kg of deionized water, and add hydrochloric acid to adjust the pH value to 3-4 under the condition of continuous stirring. After the pseudo-boehmite is completely converted into jelly, add 60kg of ZSM-11 molecular sieve material (SiO 2 / Al 2 o 3 The ratio is 100), then add 106kg of kaolin, stir well, then add 40kg of silica sol and 14kg of phosphoric acid. After stirring for 2 hours, spray granulation was carried out.

[0025] The obtained microsphere catalyst was aged for 4 hours at 800° C. and 100% steam for subsequent use.

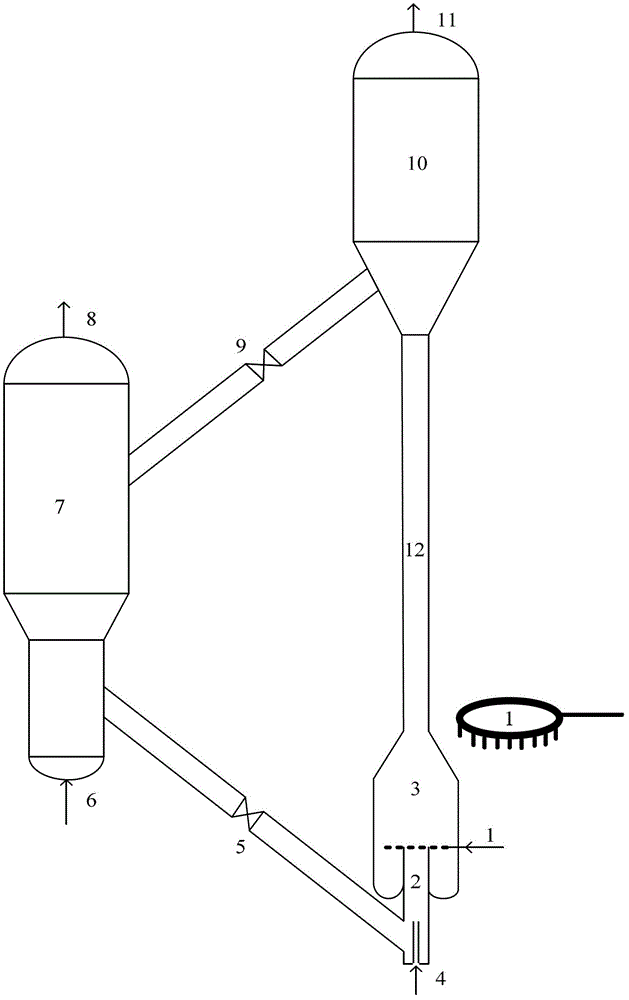

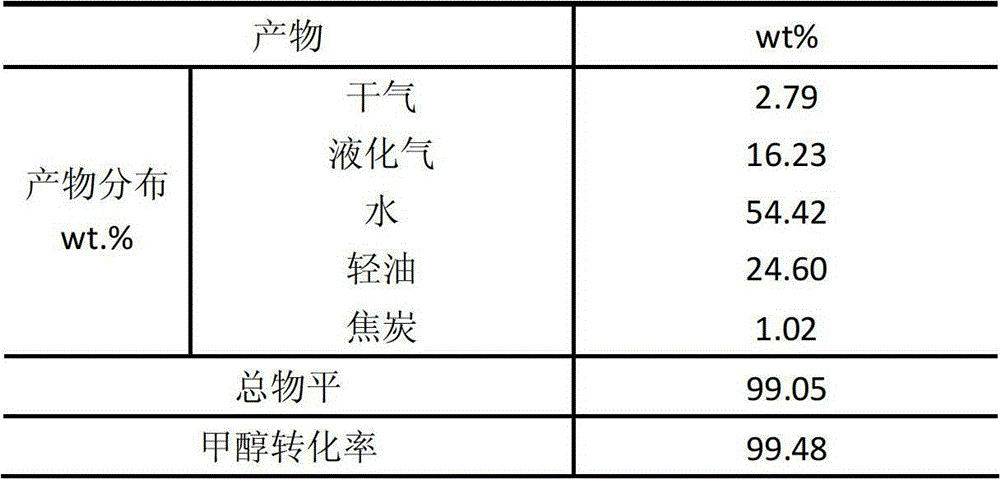

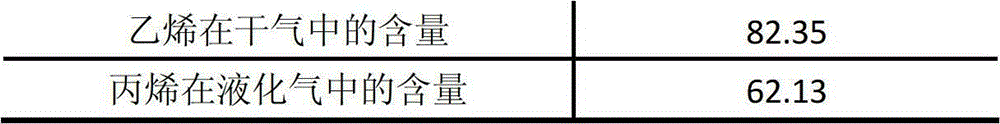

[0026] 50kg of the aged catalyst was loaded into the pilot plant constructed according to the structure shown in the accompanying drawing. The reaction temperature in the turbulent bed is controlled at 420°C; the average linear velocity of the gas in the turbulent bed is 0.45m / s, and the average residence time is about 2s; the average linear velocity of the gas in the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com