Carbon nanometer tube field emitting cathode and manufacturing method thereof

A field emission cathode and carbon nanotube technology, applied in the field emission field, can solve the problems of small field emission current, unstable emission, weak bonding force between carbon nanotube layer and conductive substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

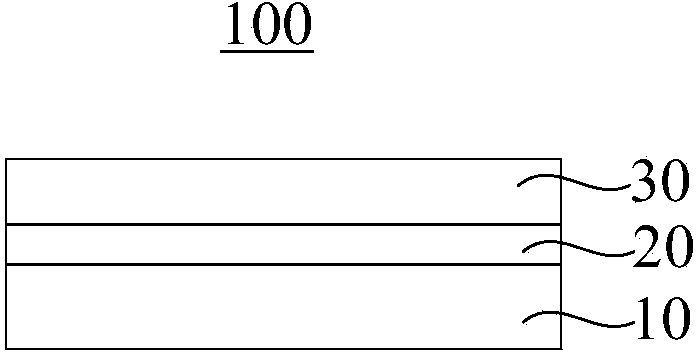

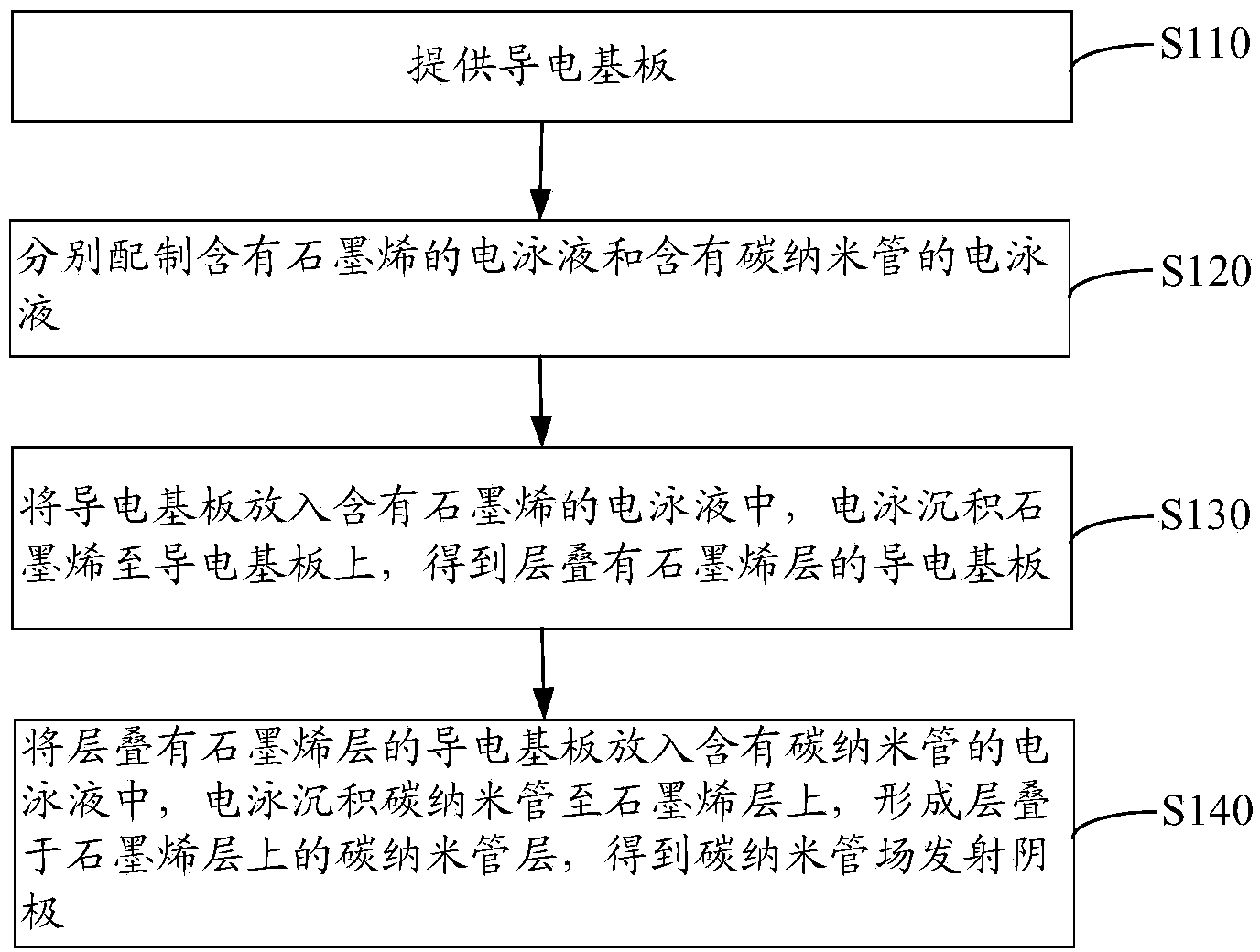

[0051] see figure 2 , the preparation method of the carbon nanotube field emission cathode of one embodiment, comprises the steps:

[0052] Step S110: providing a conductive substrate.

[0053] The conductive substrate can be a metal substrate such as a stainless steel substrate, a titanium substrate, a copper substrate, an aluminum substrate, a chromium substrate or a nickel substrate; or a metal substrate coated with tungsten, molybdenum, titanium, nickel, chromium, gold, silver or platinum Insulating substrate, wherein the insulating substrate is glass, ceramic or silicon wafer.

[0054] In another embodiment, the conductive substrate is ITO glass.

[0055] The conductive substrate was ultrasonically cleaned with acetone and ethanol for 10 minutes in sequence, and then dried with nitrogen gas for later use.

[0056] Step S120: Prepare graphene-containing electrophoretic fluid and carbon nanotube-containing electrophoretic fluid respectively.

[0057] The graphene and t...

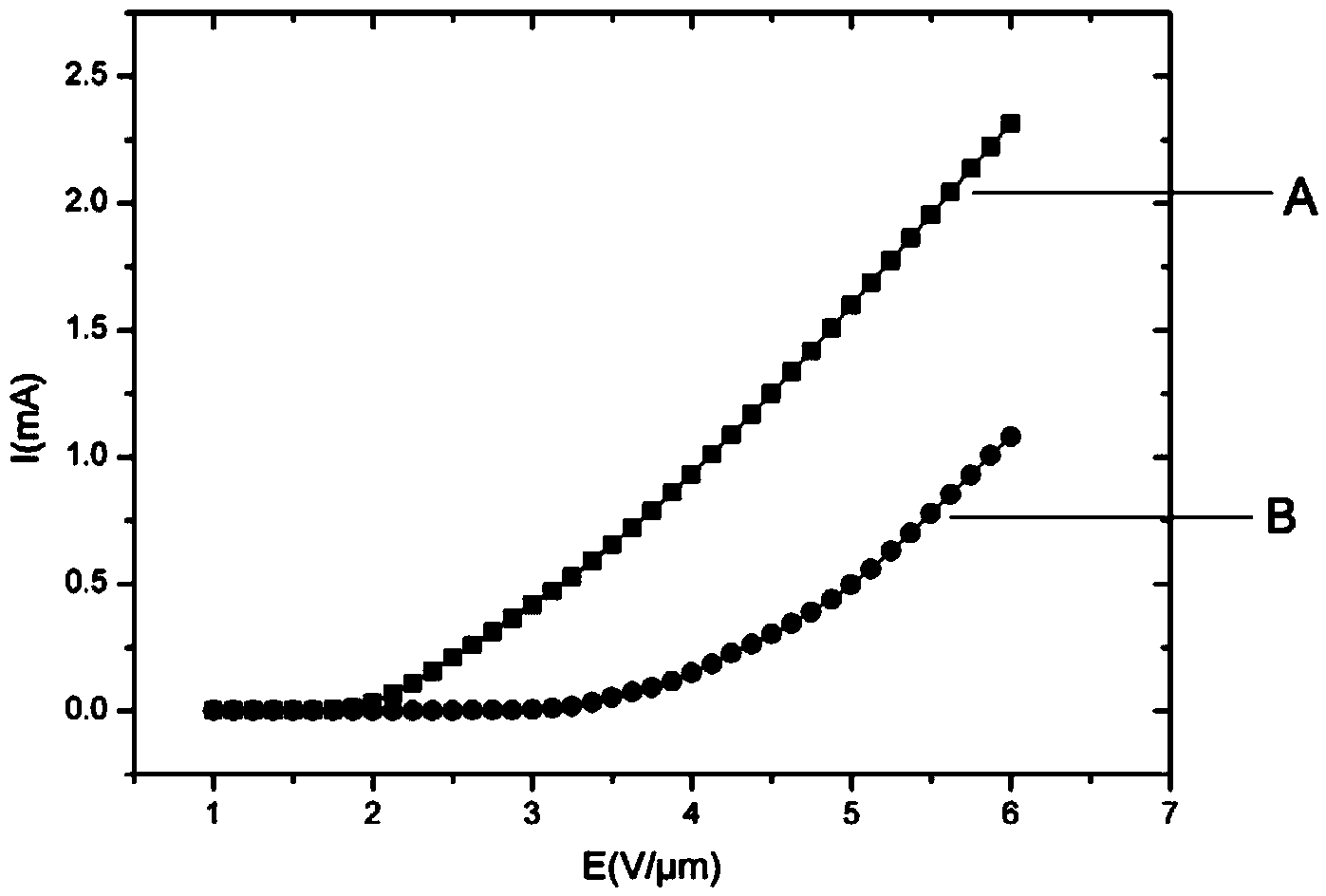

Embodiment 1

[0094] Preparation of Carbon Nanotube Field Emission Cathode

[0095] (1) Add reduced graphene with a thickness of 1.1-3.7nm to absolute ethanol, and add 50% MgCl 2 (Based on the mass of graphene) as the first charge additive, the concentration of graphene is 0.05 mg / ml, ultrasonically dispersed for 1 hour, and an electrophoretic solution containing graphene is obtained;

[0096] (2) Add multi-walled carbon nanotubes with a diameter of less than 8 nm and a length of 5 to 15 μm in absolute ethanol, and add 25% MgCl 2 (Based on the mass of carbon nanotubes) as the second charge additive, the concentration of carbon nanotubes is 0.01 mg / ml, ultrasonically dispersed for 1 hour, and an electrophoretic solution containing carbon nanotubes is obtained;

[0097] (3) ITO glass was used as the conductive substrate, the conductive substrate was used as the cathode, and the oxygen-free copper sheet was used as the anode. Before use, it was ultrasonically cleaned with acetone and ethanol ...

Embodiment 2

[0101] Preparation of Carbon Nanotube Field Emission Cathode

[0102] (1) Add graphene oxide with a thickness of 5.0-8.6nm into absolute ethanol, and add 1% Mg(NO 3 ) 2 (Based on the mass of graphene) as the first charge additive, the concentration of graphene is 0.5 mg / ml, ultrasonically dispersed for 1 hour, and an electrophoretic solution containing graphene is obtained;

[0103] (2) Add single-walled carbon nanotubes with a diameter of less than 10-20 nm and a length of 10-20 μm into absolute ethanol, and add 1% Mg(NO 3 ) 2 (Based on the mass of carbon nanotubes) as the second charge additive, the concentration of carbon nanotubes is 0.1 mg / ml, ultrasonically dispersed for 3 hours, and an electrophoretic solution containing carbon nanotubes is obtained;

[0104] (3) The glass substrate deposited with a metal titanium layer was used as the conductive substrate, the conductive substrate was used as the cathode, and the stainless steel sheet was used as the anode. Before u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com