Hollow nanosphere material as well as preparation method and application thereof

A technology of nanospheres and carbon nanospheres, which is applied in nanocarbons, chemical instruments and methods, and pharmaceutical formulations, and can solve problems such as collapse, rupture, and difficulty in maintaining three-dimensional network gel pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) adopt Monodisperse silica nanospheres were prepared by the following method: Prepare ethanol / tetraethyl orthosilicate (202.5mL / 22.4mL) and ethanol / ammonia / water (112.5mL / 8.4mL / 104.1 mL) of the mixed solution, and quickly mixed evenly, set the stirring rate to 250rpm, and reacted at 30°C for 3h to obtain monodisperse silica nanospheres. Then, 2ml of silane coupling agent KH-570 was dissolved in 100ml of ethanol, and added into the above reaction system with a dropping funnel, and the reaction was continued for 36h after the addition was completed, to obtain modified silica nanospheres.

[0054] (2) Dissolve 0.03g of sodium dodecylbenzenesulfonate and 0.24g of sodium bicarbonate in 100mL of deionized water that has been deoxygenated beforehand, stir well until the system is uniform, and pass nitrogen gas into the system for 15 minutes to remove oxygen. Then, ultrasonically dispersed modified silica ethanol dispersion (1.2 g of modified silica nanospheres prepared in...

Embodiment 2

[0062] (1) The preparation of hollow polymer nanospheres is the same as the steps (1) to (4) of Example 1.

[0063] (2) Put the hollow polymer nanosphere material prepared above in a carbonization furnace, raise the temperature to 900°C at a heating rate of 5°C / min under an inert gas atmosphere, and then carbonize at a constant temperature for 3 hours to obtain hollow carbon nanospheres Material.

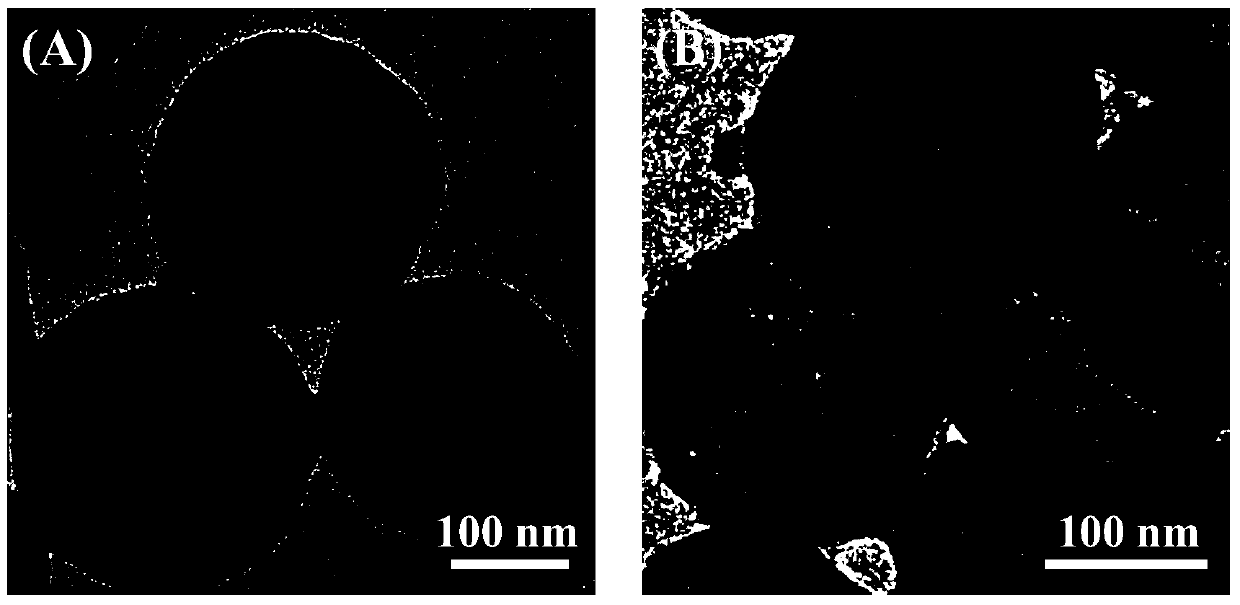

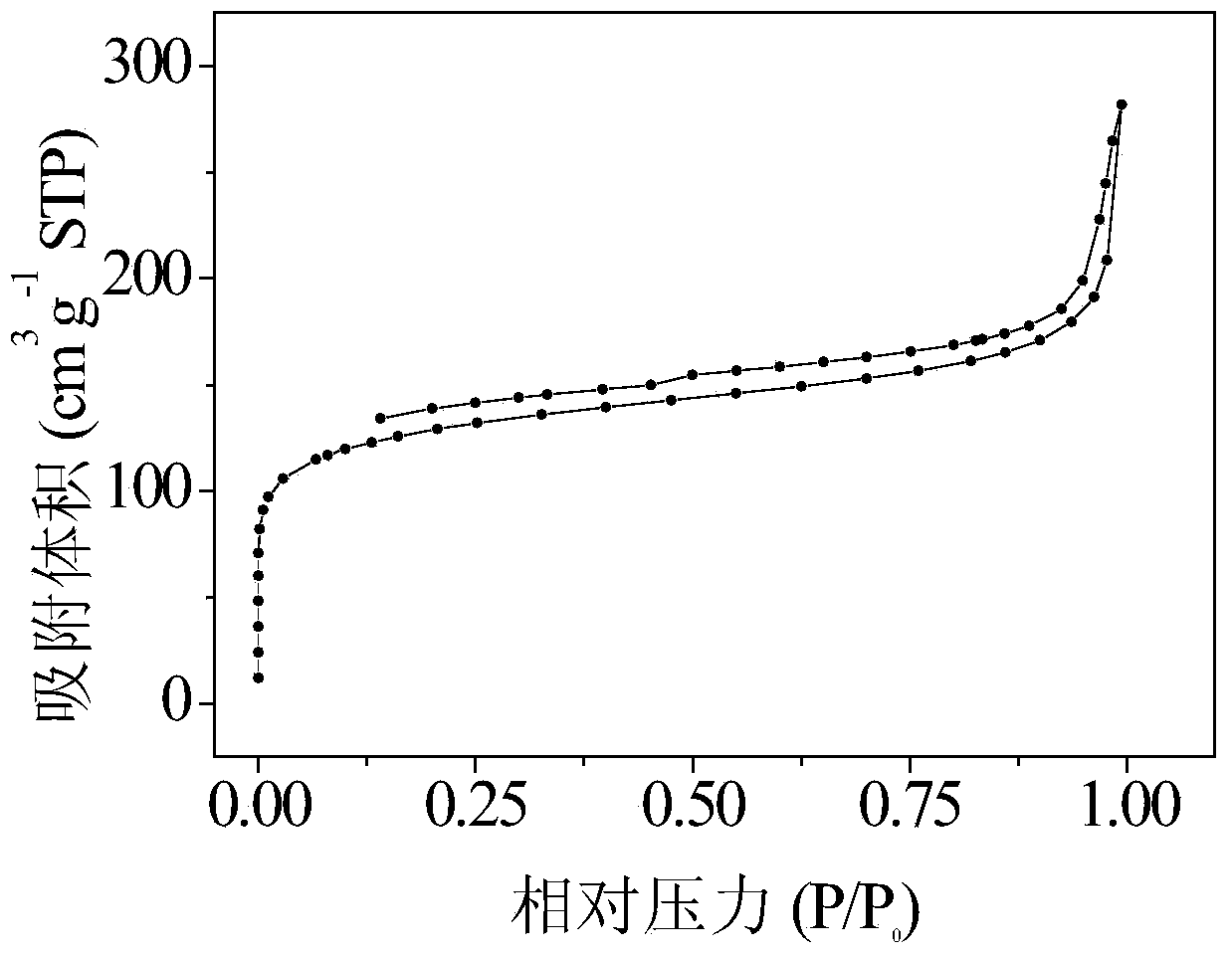

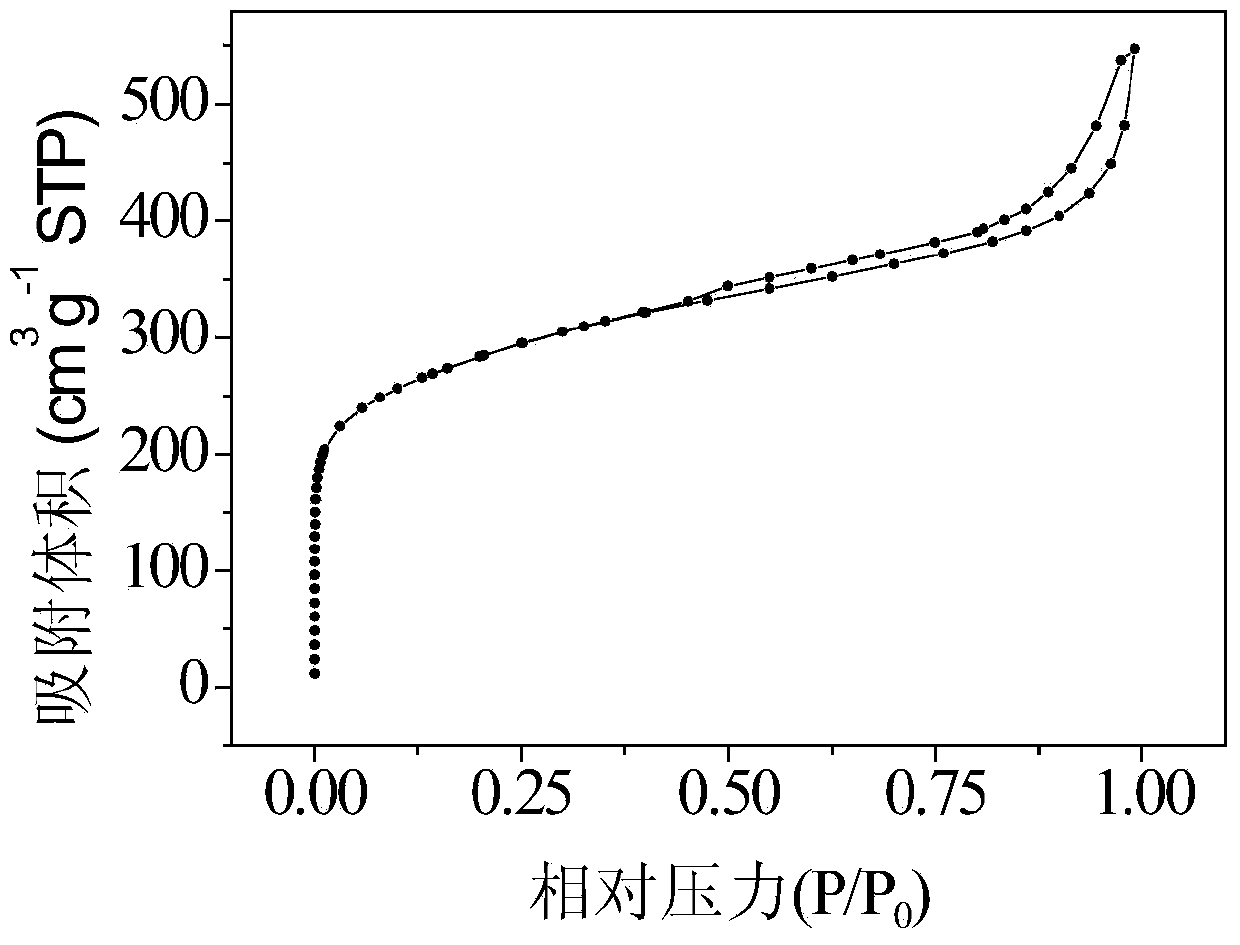

[0064] The ASAP2020 adsorption instrument nitrogen adsorption method produced by Micromeritics Company of the United States was used for testing. see test results Figure 4 , the BET specific surface area of the prepared hollow carbon nanospheres is 1034m 2 g - , where the surface areas of micropores and external pores are 848 m 2 g - and 186m 2 g - ; total pore volume in cm 3 g -1 , where the micropore volume and the external pore volume are 0.40 cm 3 g -1 and 0.43cm 3 g -1 .

[0065] The above-mentioned hollow carbon nanospheres were used as the electrode material,...

Embodiment 3

[0067] (1) The preparation of monodisperse silica nanospheres is the same as in Example 1.

[0068] (2) Dissolve 0.03g of sodium dodecylbenzenesulfonate and 0.24g of sodium bicarbonate in 100mL of deionized water that has been deoxygenated beforehand, stir well until the system is uniform, and pass nitrogen gas into the system for 15 minutes to remove oxygen. Then ultrasonically dispersed modified silica ethanol dispersion (1.2 g of silica nanospheres dispersed in 10 mL of ethanol) was added and vigorously stirred. After the system is uniform, add 10mL of styrene and 3mL of divinylbenzene to the system, stir for 10min, then raise the temperature to 75°C, add 0.12g of initiator potassium persulfate, react for 24h, centrifuge and wash with toluene to remove the surfactant.

[0069] (3) Disperse 1 g of the pre-crosslinked polymer nanospheres obtained in (2) above in 60 ml of carbon tetrachloride and swell for 12 h, then raise the temperature to 75 ° C, add 2.8 g of anhydrous alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com