Purine nucleoside phosphorylase and preparation method thereof

A purine nucleoside phosphorylase and polynucleotide technology, which is applied in the field of genetic engineering, can solve the problems of low PNP yield, inactivation, EcPNP changes sharply at 50-55 ℃, and the effect cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] (3) The preparation method of the present invention greatly improves the output of purine nucleoside phosphorylase, and the expression activity of the product can reach or exceed 400U / mL, which is beyond the reach of the current genetic engineering preparation method. Thereby it is conducive to large-scale industrial production.

[0082] The above-mentioned features mentioned in the present invention, or the features mentioned in the embodiments can be combined arbitrarily. All the features disclosed in the specification of this case can be used in combination with any combination, and each feature disclosed in the specification can be replaced by any alternative feature that provides the same, equivalent or similar purpose. Therefore, unless otherwise specified, the disclosed features are only general examples of equivalent or similar features.

Embodiment 1

[0094] Example 1 Optimization of Pseudoalteromonas (Pseudoalteromonas) PNP gene sequence and construction of cloning vector

[0095] ① Optimization of gene sequence

[0096] The optimization of the gene sequence is to partially modify the PNP gene sequence (GEN BANK EF222283, SEQ ID NO.3) of Pseudoalteromonas sp.i590, which is divided into two parts: one is to convert the Arg2 and Leu24 encoding amino acids in the entire sequence , Leu77, Ile87, Leu134, Leu145 codons AGG, CTA, CTA, ATA, CTA, CTA were changed to CGA, CTG, CTG, ATC, CTG, CTG; the second is to transform the 97-position Asp into Tyr, and the codon is changed from GAC Change to TAT. The optimized gene sequence is used for whole gene synthesis.

[0097] Whole Gene Synthesis:

[0098] Entrust Shanghai Sangong Synthetic Co., Ltd. Firstly, the wild-type PNP gene sequence of Pseudoalteromonas sp.i590 was obtained from the NCBI database, and the codon of the 97th amino acid residue was changed from Asp97 to Tyr. In ...

Embodiment 2

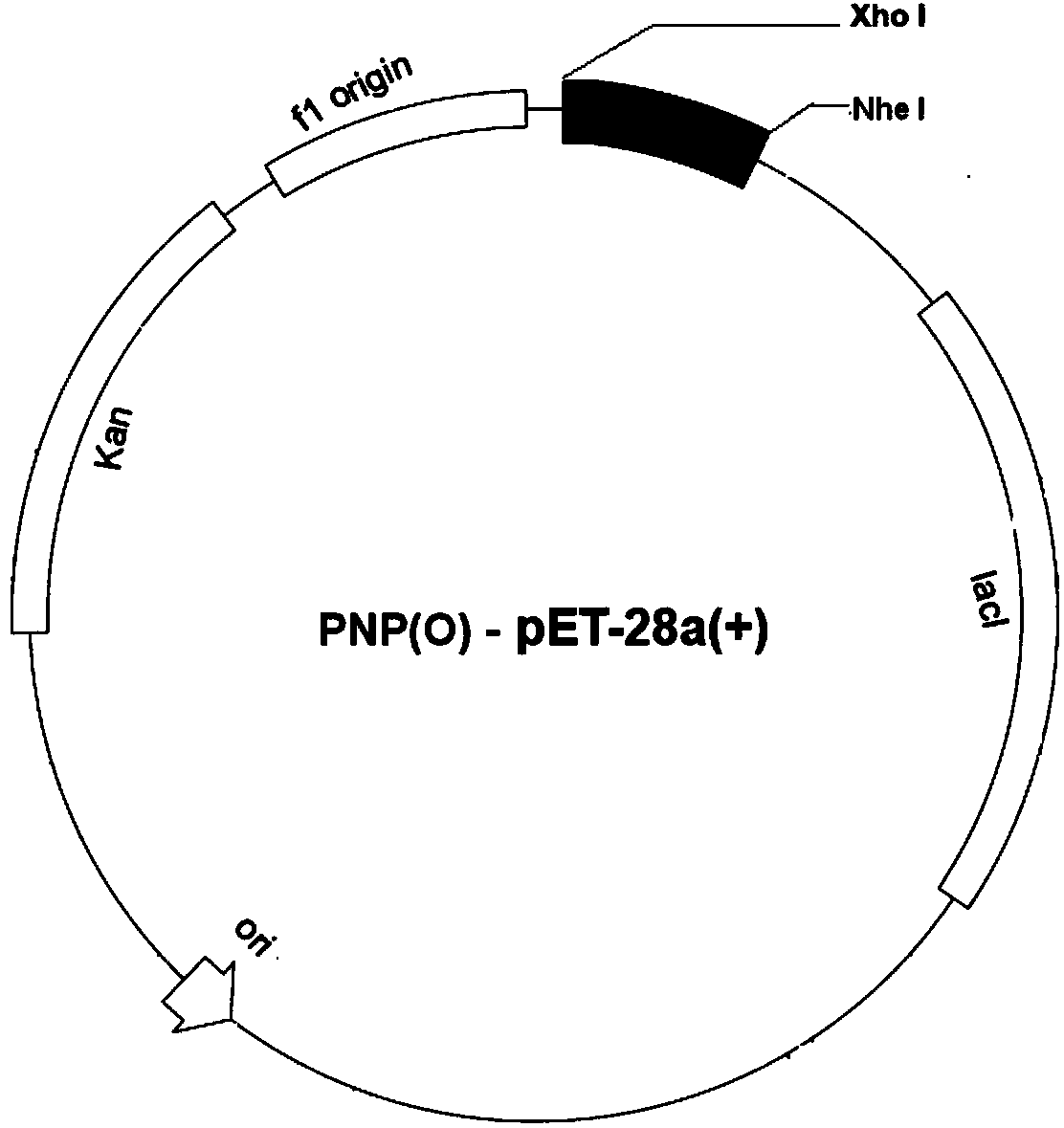

[0120] Example 2 Construction of PNP(O)-pET-28a(+)-BL21 Expression Engineering Bacteria

[0121] ①Plasmid extraction

[0122] The positive clones with correct sequencing were inoculated into LBA medium, cultured with shaking at 37°C and 220 rpm for 12 hours, and the recombinant plasmid was extracted with BIOMIGA's Plasmid Miniprep Kit. For specific operation methods, please refer to the instruction manual.

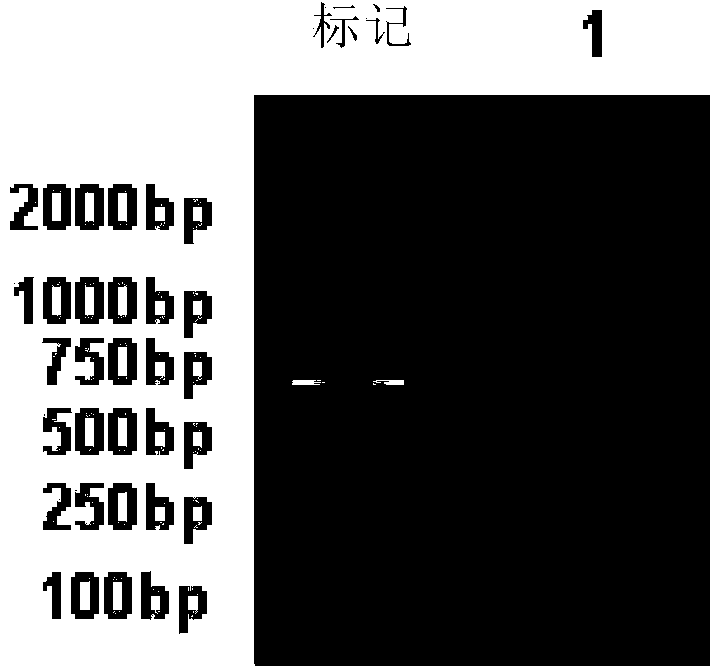

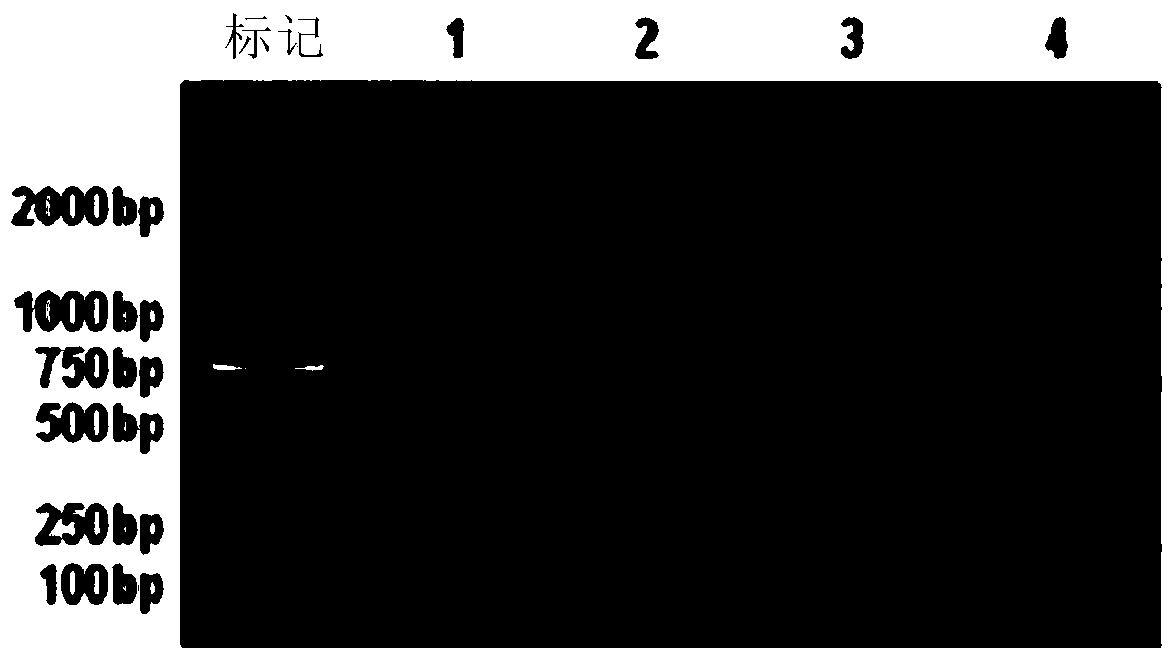

[0124] Both PNP(O)-pMD19T-BL21 and the vector pET-28a(+) were digested with Nhe I and Xho I, overnight at 37°C; all digested products were used for agarose gel horizontal plate electrophoresis at a gel concentration of 1.0 %(W / V), based on TaKaRa's DL2000 TM DNA Marker was used as DNA molecular weight standard; after electrophoresis, the target fragment was recovered with UNIQ-10 Column DNA Gel Recovery Kit.

[0125] ③ connection

[0126] The connection system is shown in Table 4, and connected overnight at 16°C. The plasmid map of the resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com