Lithium ion battery and preparation method thereof

A lithium-ion battery and electrolyte technology, applied in the field of electrochemistry, can solve the problems of low capacity of positive electrode materials and slow lithium insertion speed, and achieve the effects of easy large-scale production, improving the ability to store electric charges, and increasing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

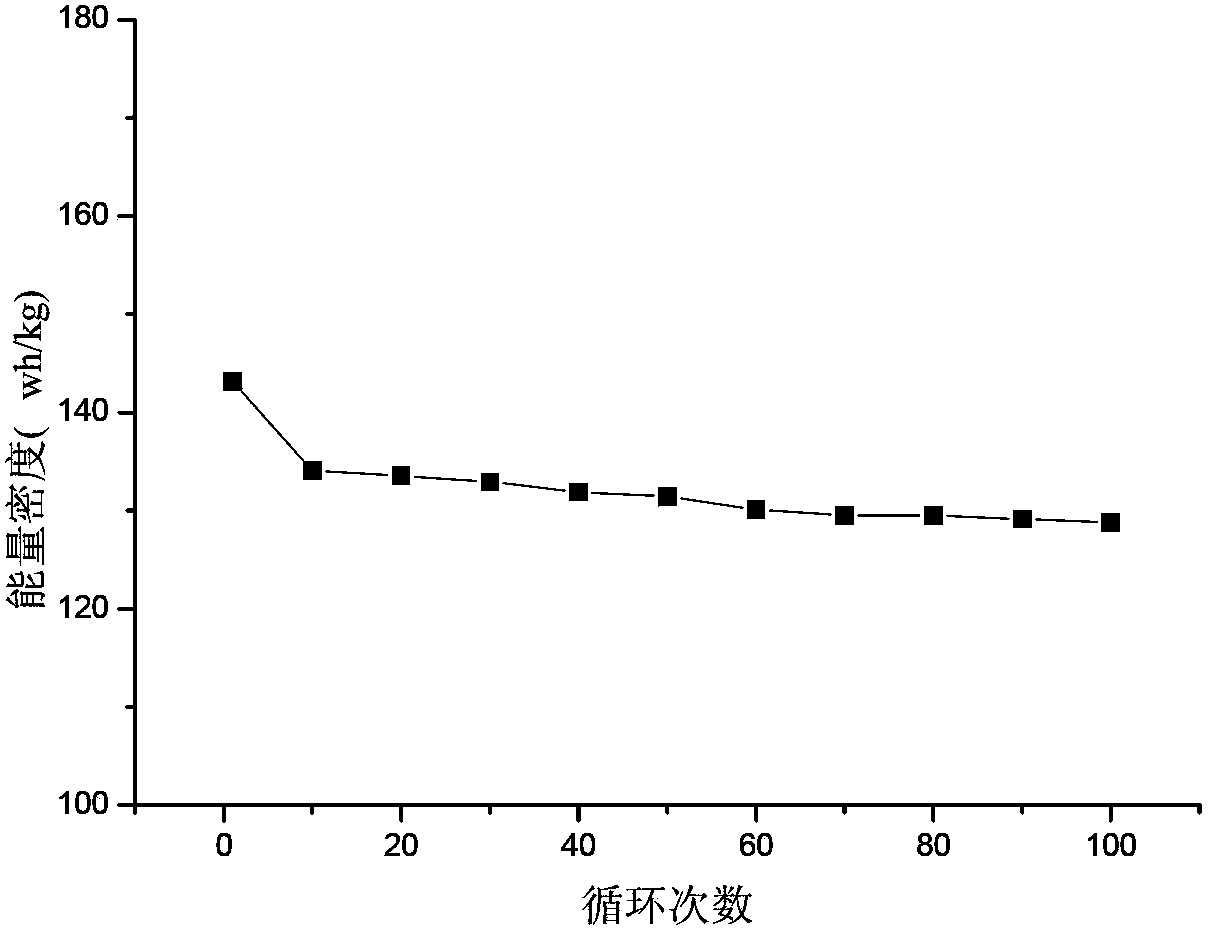

Image

Examples

preparation example Construction

[0050] In addition, the present invention also provides a kind of preparation method of lithium ion battery, comprises the following steps:

[0051] Step (1) Preparation of positive and negative electrodes:

[0052] Mix the positive electrode active material, binder and conductive agent uniformly in a mass ratio of 85-90:5-10:5-10 to obtain a mixed slurry, coat the mixed slurry on an aluminum foil, and dry , film rolling, and edge trimming to obtain the positive electrode sheet of lithium-ion battery; wherein, the positive electrode active material has a specific surface area of 1~20m 2 / g of graphite;

[0053] Mix the negative electrode active material, binder and conductive agent uniformly in a mass ratio of 85-90:5-10:5-10 to obtain a mixed slurry, coat the mixed slurry on an aluminum foil, and dry , film rolling, and edge trimming to obtain lithium-ion battery anode sheets; wherein, the anode active material has a specific surface area of 200~3000m 2 / g carbon mater...

Embodiment 1

[0071] A preparation method for a lithium ion battery, comprising the following steps:

[0072] (1) The specific surface area of 25.5g is 1m 2 / g of graphite, 1.5g of polyvinylidene fluoride binder and 3g of acetylene black conductive agent are mixed evenly to obtain a mixed slurry, which is coated on an aluminum foil, dried, rolled, and trimmed to obtain a Lithium-ion battery positive plate;

[0073] (2) The specific surface area of 8.5g is 1500m 2 Graphene / g, 0.5g polyvinylidene fluoride binder, and 1g acetylene black conductive agent were mixed evenly to obtain a mixed slurry, which was coated on an aluminum foil, dried, rolled, and edge-trimmed. Obtain lithium-ion battery negative plate;

[0074] In this embodiment, the mass ratio of the negative electrode active material to the positive electrode active material is 1:3;

[0075] (3) Take the polypropylene diaphragm, assemble it with the positive electrode sheet and the negative electrode sheet stack to form a batt...

Embodiment 2

[0079] A preparation method for a lithium ion battery, comprising the following steps:

[0080] (1) The specific surface area of 127.5g is 20m 2 Graphite / g, 15g polytetrafluoroethylene binder and 7.5g Ketjen black conductive agent are mixed evenly to obtain mixed slurry, which is coated on aluminum foil, and processed by drying, film rolling and trimming. Obtain lithium-ion battery positive plate;

[0081] (2) The specific surface area of 8.5g is 1500m 2Nitrogen-doped graphene / g, 1g polytetrafluoroethylene binder and 0.5g Ketjen black conductive agent are mixed evenly to obtain a mixed slurry, which is coated on an aluminum foil, dried, rolled, cut Side processing, made lithium-ion battery negative plate;

[0082] In this embodiment, the mass ratio of the negative electrode active material to the positive electrode active material is 1:15;

[0083] (3) Take the polyethylene diaphragm, assemble it with the positive electrode sheet and the negative electrode sheet stack ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com