A fungus superfine powder iron-replenishing beverage and its production process

A production process and ultrafine powder technology, which is applied in the directions of protein-containing food ingredients, bacteria used in food preparation, and functions of food ingredients, etc., can solve the problems of affecting the taking effect and the instability of ferrous lactate compounds to light, and achieve the solution Dissolution problems, good absorption, improved dissolution and release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

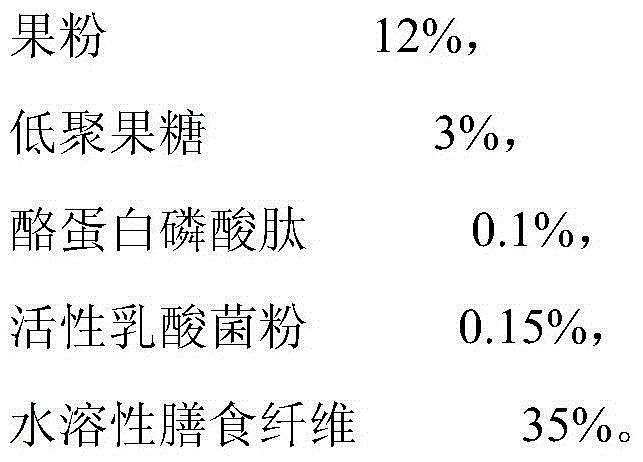

[0034] Embodiment 1: Basic iron supplement formula (1)

[0035] The basic components include main ingredients and auxiliary materials. The main ingredients are 400-1200 mesh fungus superfine powder, and the auxiliary materials include fruit powder, fructooligosaccharides and casein phosphopeptides;

[0036] The mass ratio of each composition in the base component is:

[0037] Fruit powder 12%,

[0038] fructo-oligosaccharides 3%,

[0039] Casein Phosphopeptide 0.1%,

[0040] The rest is superfine powder of fungus.

[0041] Production steps of the present invention are as follows:

[0042] (1) Select high-quality fungus, after cleaning, microwave drying for later use;

[0043] (2) Instantly sterilize the fungus at 135°C for 5 seconds at high temperature;

[0044] (3) Under the condition of -30°C, the fungus is vibrated at a high frequency by a vibrating rod, closed-type ultrafine pulverization, and the pulverized fungus powder is 400-1200 mesh;

[0045] (4) After mixing ...

Embodiment 2

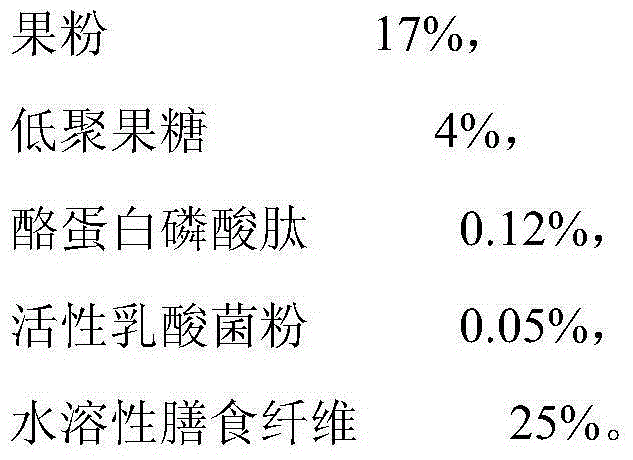

[0057] Embodiment two: Basic formula for supplementing iron (two)

[0058] The mass ratio of each composition in the base component is:

[0059] Fruit powder 18%,

[0060] fructo-oligosaccharides 6%,

[0061] Casein Phosphopeptide 0.15%,

[0062] The rest is superfine powder of fungus.

[0063] All the other methods of making and eating are the same as in Example 1, and will not be repeated.

Embodiment 3

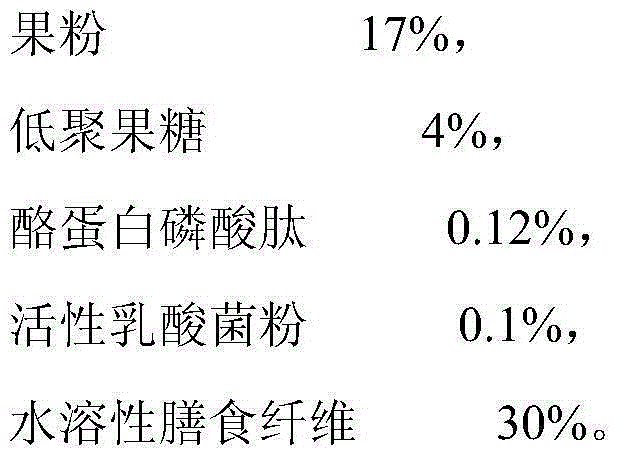

[0064] Embodiment three: Basic formula for supplementing iron (three)

[0065] The mass ratio of each composition in the base component is:

[0066] Fruit powder 16%,

[0067] fructooligosaccharides 5%,

[0068] Casein Phosphopeptide 0.12%,

[0069] The rest is superfine powder of fungus.

[0070] All the other methods of making and eating are the same as in Example 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com