Microwave hydro-thermal synthesis method of zinc oxide nanostructure modified timber

A zinc oxide nanometer, microwave hydrothermal technology, applied in the direction of wood impregnation, wood impregnation, wood processing equipment, etc. The effect of thermal response time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

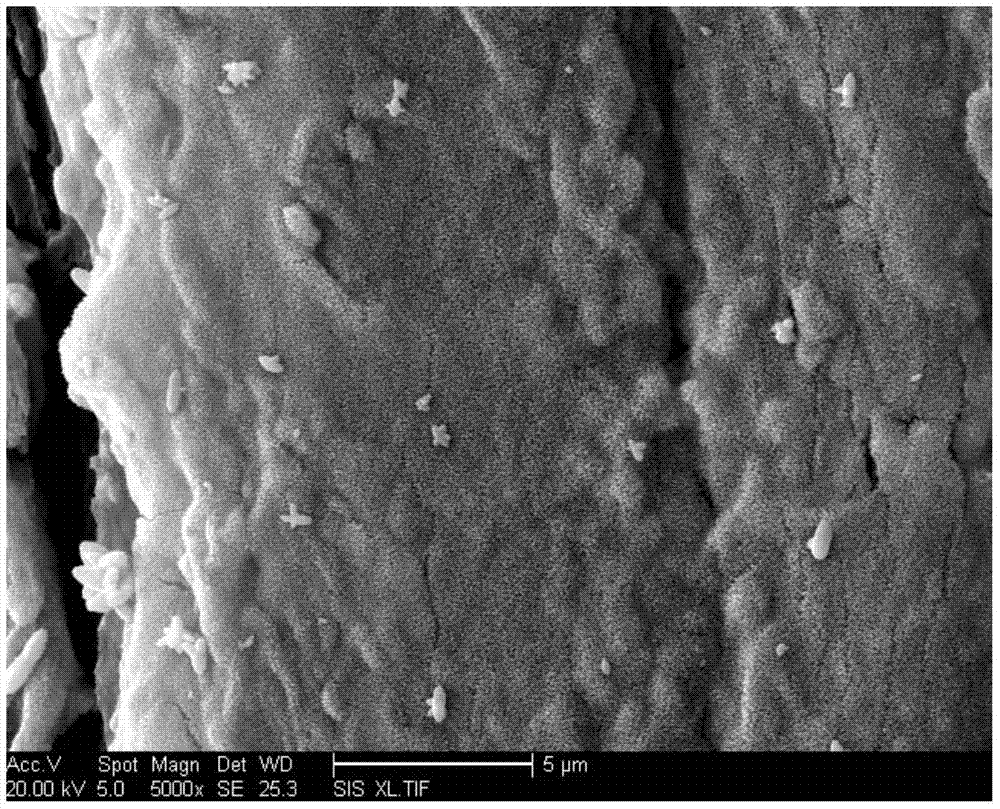

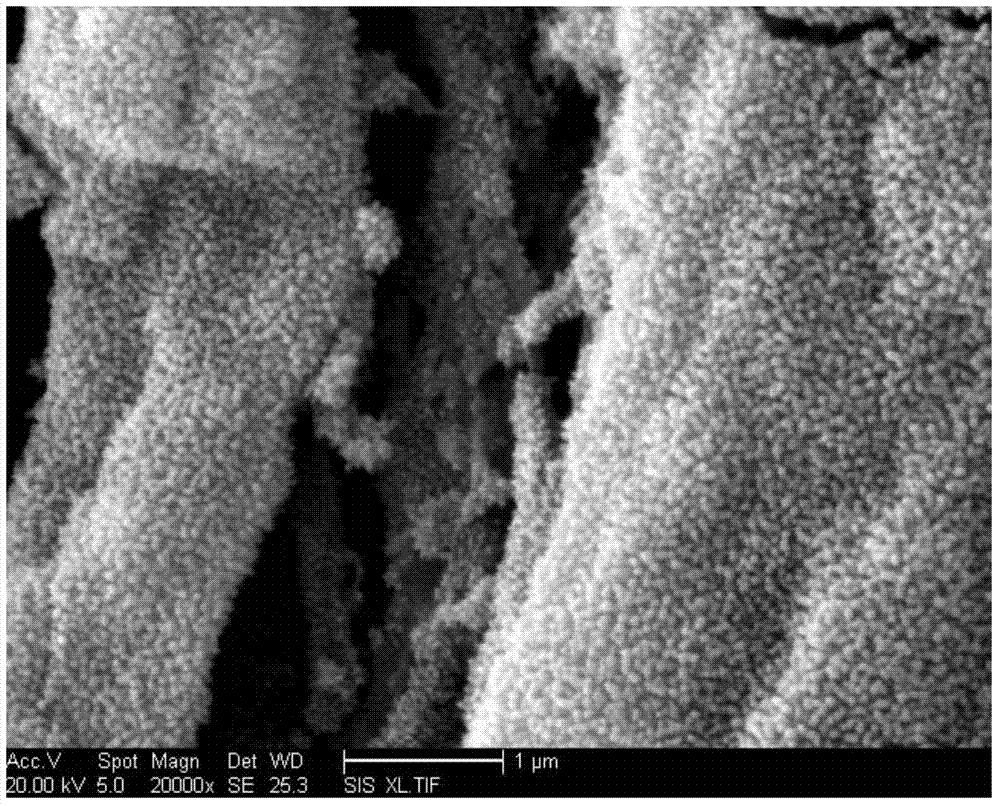

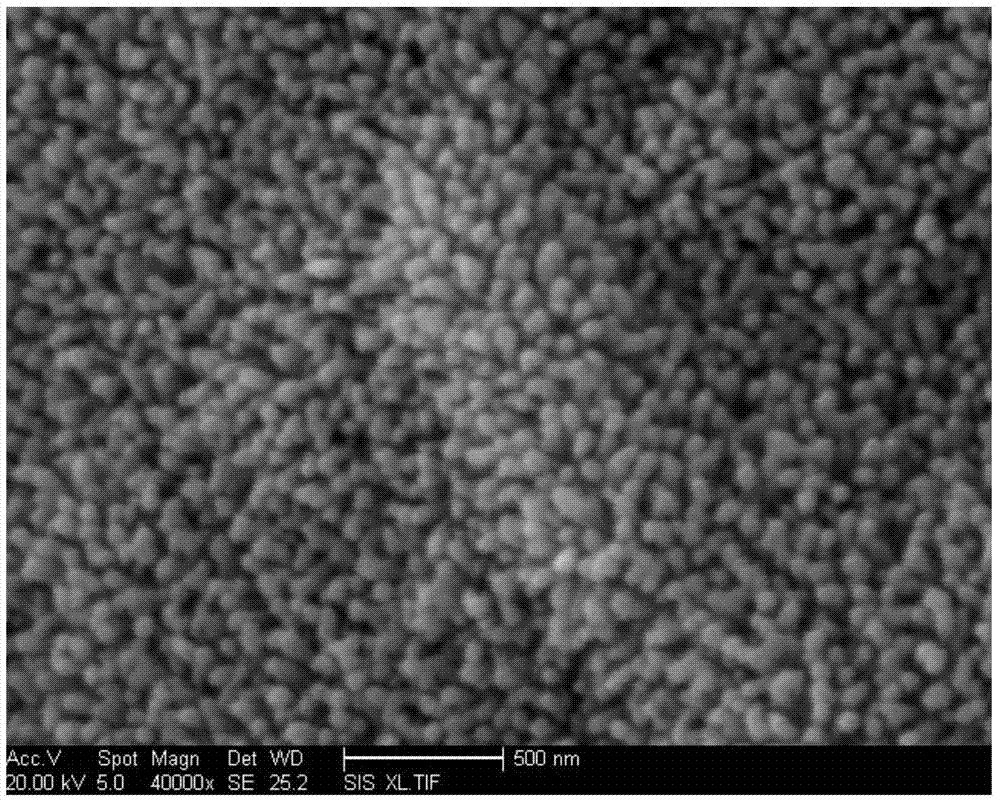

[0030] Specific embodiment one: In this embodiment, a method for microwave hydrothermal synthesis of zinc oxide nanostructure modified wood is realized according to the following steps:

[0031] 1. Stir the zinc acetate-alcohol solution and the sodium hydroxide-alcohol solution evenly to obtain a ZnO seed crystal colloidal solution; wherein the molar ratio of zinc acetate and sodium hydroxide is 1:1 to 5;

[0032] 2. Soak the wood in the ZnO seed crystal colloid solution prepared in step 1 and keep it for 6-48 hours, then dry the wood, repeat soaking-drying 1-5 times, and obtain the wood with ZnO seed crystals growing on the surface;

[0033]3. Mix the zinc salt aqueous solution and the ammonia source aqueous solution at a ratio of 1:1 to 5 in the molar ratio of the zinc salt to the ammonia source to obtain a blend solution, wherein the molar concentration of the zinc salt is 0.005 to 0.1mol / L; The mixed liquid was ultrasonically dispersed for 5-30 minutes, and then the blende...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the alcohol described in step one is absolute ethanol (analytically pure). Others are the same as in Embodiment 1.

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and one of specific embodiments one to two is that the molar ratio of zinc acetate and sodium hydroxide described in step one is 1:1-3. Others are the same as one of the specific embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com