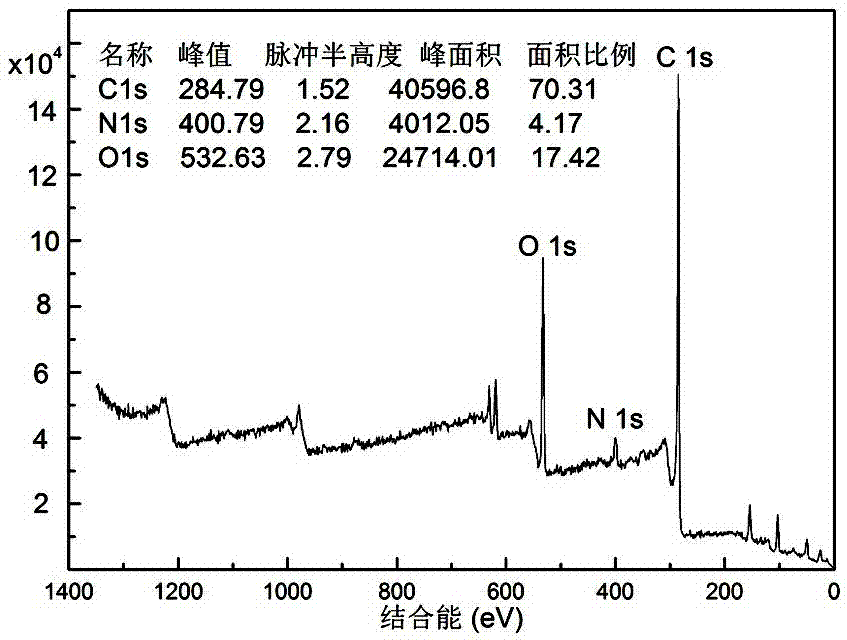

Preparation method and application of sludge activated carbon

A sludge activated carbon and sludge drying technology, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of not finding a preparation method for sludge activated carbon, and achieve a simple and easy preparation method line, avoid pollution, reduce the effect of treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

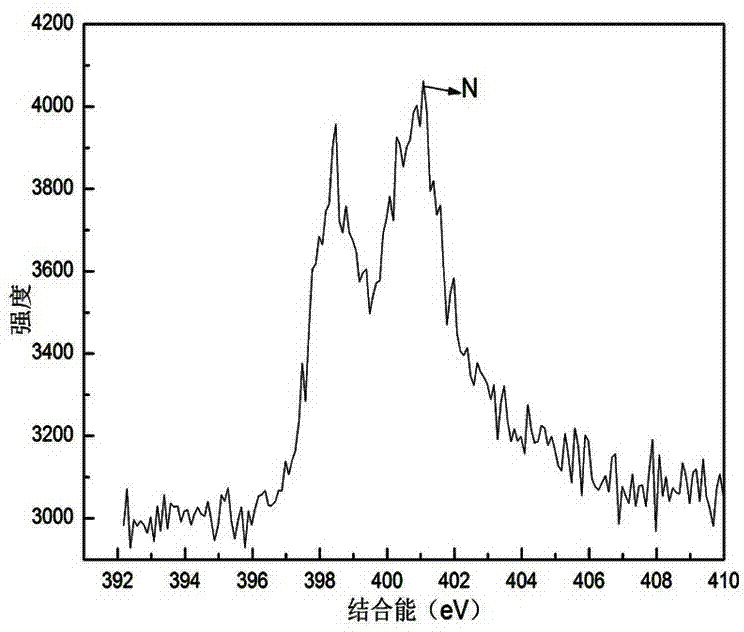

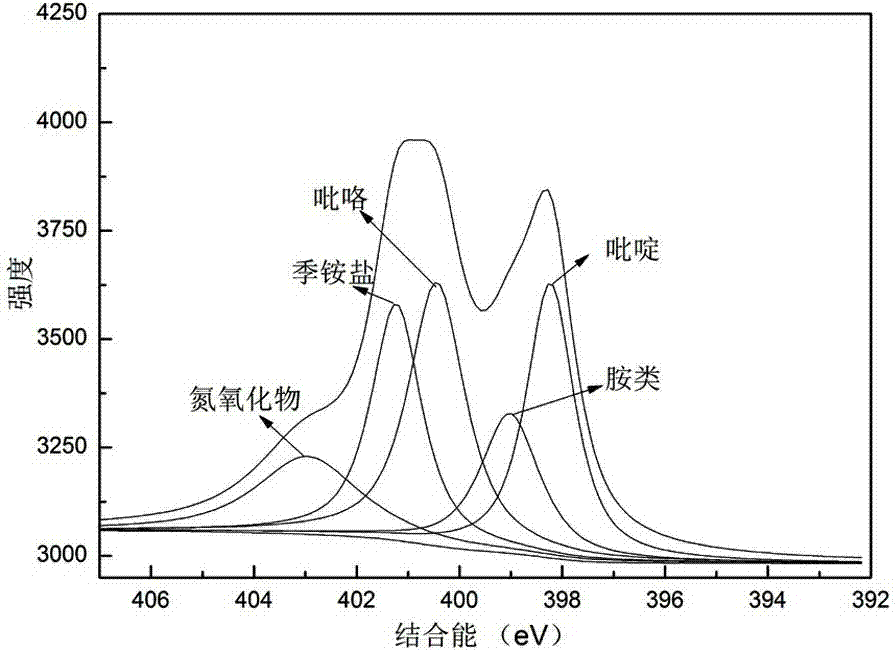

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the sludge activated carbon of the present embodiment may further comprise the steps:

[0036] (1) After drying the remaining sludge from the sewage treatment plant at 105°C for 48 hours, crush it and pass it through 200-mesh and 300-mesh sieves successively, take 10g of the sieved sludge and put it into a tubular resistance furnace, and use 80mL / Ammonia gas was introduced at a flow rate of 25°C / min, the temperature was raised to 110°C at a rate of 25°C / min, and the temperature was raised to 110°C for 5 minutes, then the temperature was raised to a final reaction temperature of 500°C at a rate of 25°C / min, and the temperature was raised to 500°C at a rate of 25°C / min. pH=6.8, and finally dried at a constant temperature of 105°C for 24 hours to obtain sludge activated carbon powder raw material;

[0037] (2) Add 10g of sludge activated carbon powder raw material to 200mL of hydrogen peroxide solution with a mass concentration of 10%, then oscil...

Embodiment 2

[0043] The sludge activated carbon of the present embodiment handles the application of low-concentration perchlorate aqueous solution, comprises the following steps:

[0044] The adsorption system adopted in this embodiment, such as Figure 4 shown. The adsorption system includes an adsorption column 2, the two ends of the adsorption column 2 are respectively connected with the water inlet pipe 5 and the water outlet pipe 1, the water inlet pipe 5 is connected with a peristaltic pump 6, and the end of the water inlet pipe 5 far away from the adsorption column 2 is passed into the original solution Pool 7.

[0045] Concrete implementation is as follows: be 10cm with a length, the plexiglass column that diameter is 6cm is as adsorption column 2, offers a diameter along the length direction and is the through packed column 4 of 3mm, respectively widens a length at packed column 4 two ends. 8mm and 6mm in diameter threaded holes, respectively install a metal casing with an inne...

Embodiment 3

[0049] The regeneration of the sludge activated carbon of the present embodiment and application thereof, comprises the following steps:

[0050] The fully penetrated sludge activated carbon was dried at 105°C for 24 hours, then heated to 500°C in a microwave oven under the protection of nitrogen, and kept at a constant temperature for 10 minutes. 2 Under the environment heated to 800 ℃ for 60min, the regenerated sludge activated carbon was obtained; the regenerated sludge activated carbon was continued to be put back into the packed column 4, and the concentration was 80 μg / L sodium perchlorate aqueous solution under the same adsorption conditions as in Example 2 for adsorption.

[0051] The results showed that perchlorate ions were not detected when the treated water volume was 2000BV, and the water sample volume was 4020BV when the regenerated sludge activated carbon completely penetrated. After calculation, the adsorption capacity of activated carbon from recycled sludge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com