Preparation method for microcrystal alpha-Al2O3 aggregation

A technology of aggregates and microcrystals, applied in the preparation of alumina/hydroxide, etc., can solve the problems of high impurity content, complicated process, low reactivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

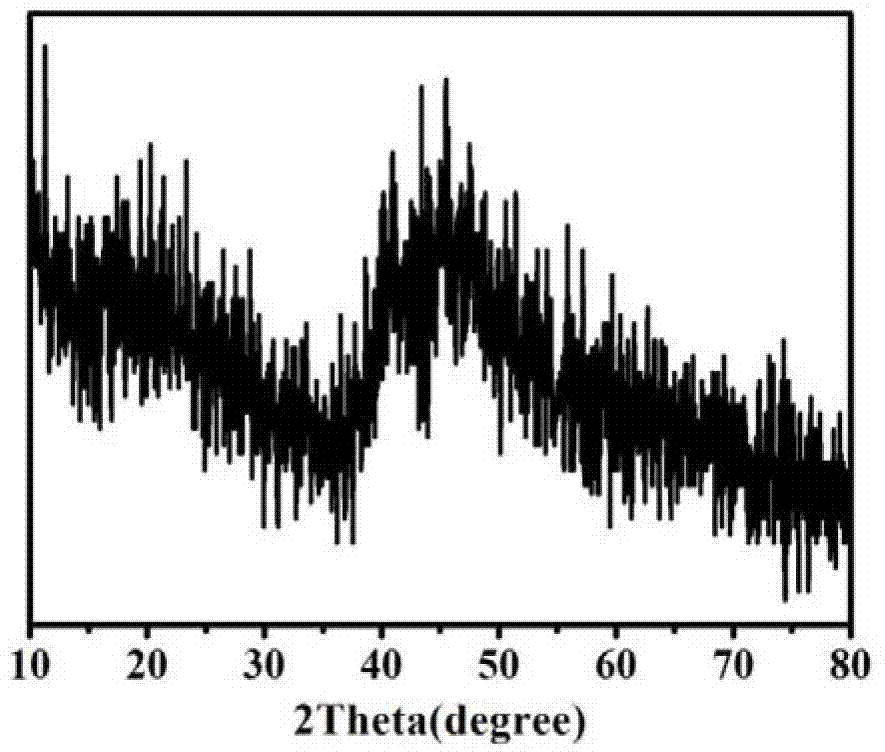

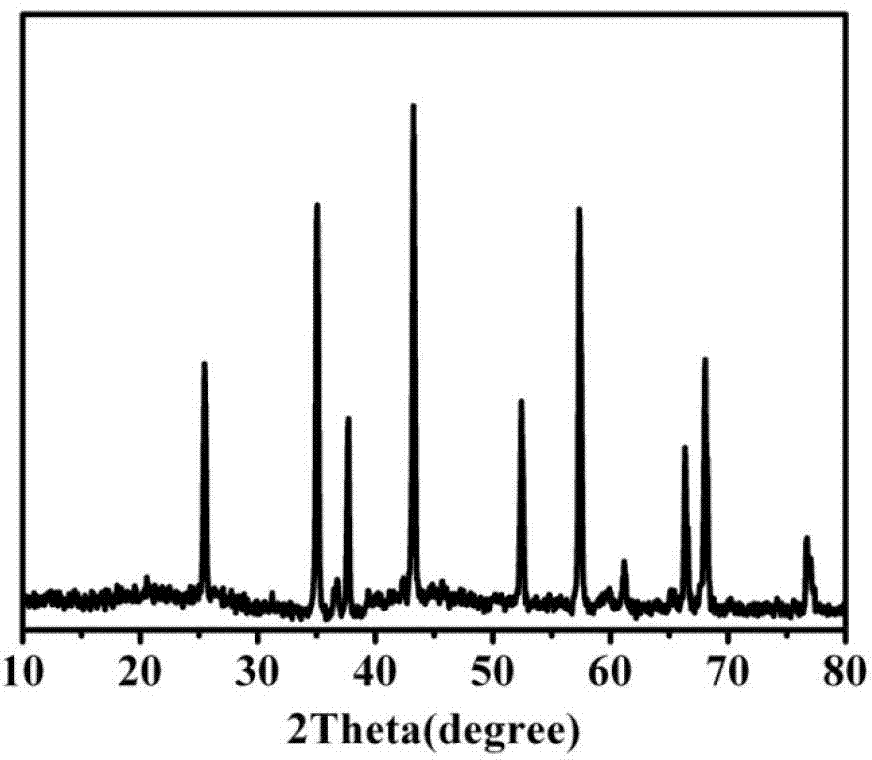

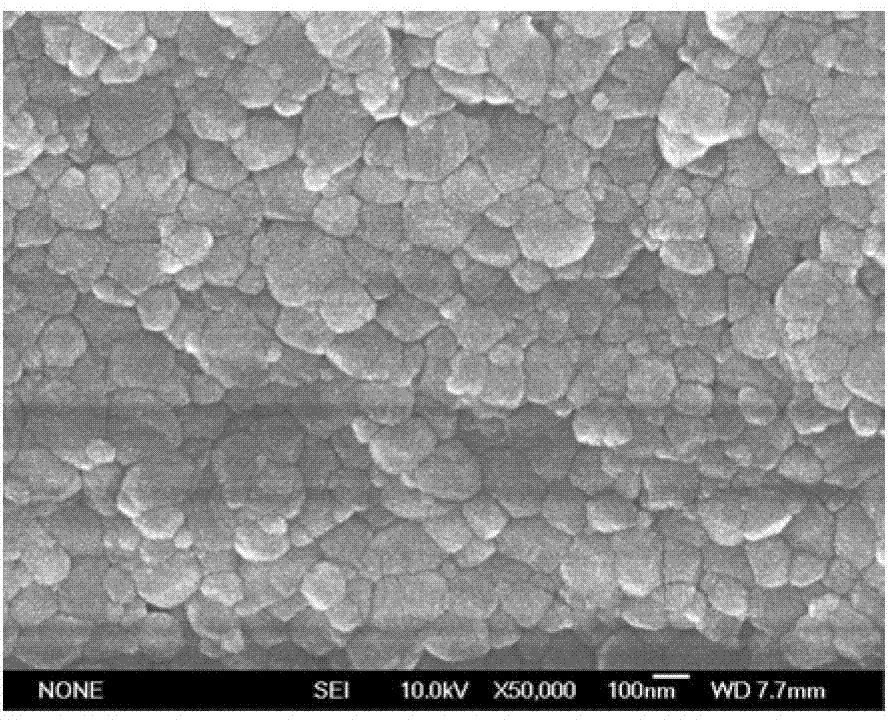

[0014] An aluminum hydroxide gel, wherein the aluminum hydroxide is amorphous, used to prepare microcrystalline α-Al 2 o 3 Aggregates; are prepared in the following steps:

[0015] (1) NH with a concentration of 25-28wt% 3 ·H 2 O added to water and Al(NO 3 ) 3 9H 2 In the mixed solution of O, Al(NO 3 ) 3 9H 2 O:H 2 O: NH 3 ·H 2 The molar ratio of O is 1:(3-8):(4.5-12), and the suspension is obtained after stirring evenly; centrifuged or suction filtered, and the precipitate is washed 2 to 3 times with deionized water to obtain aluminum hydroxide; the filtrate Used to recover by-product ammonium nitrate.

[0016] (2) adding water to the aluminum hydroxide prepared in step (1) is mixed with a suspension with a solid content of 5 to 15wt%, and adding concentrated nitric acid with a concentration of 65 to 69wt%; the mol ratio of the aluminum hydroxide to the concentrated nitric acid (5 -12): 1. Stir for 2 to 5 hours, add alumina ball milling medium to the suspension, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com